FUTABA GV-1 User manual

Other FUTABA Toy manuals

FUTABA

FUTABA CGY750 User manual

FUTABA

FUTABA SkyLeaf BP User manual

FUTABA

FUTABA SkyLeaf-ST User manual

FUTABA

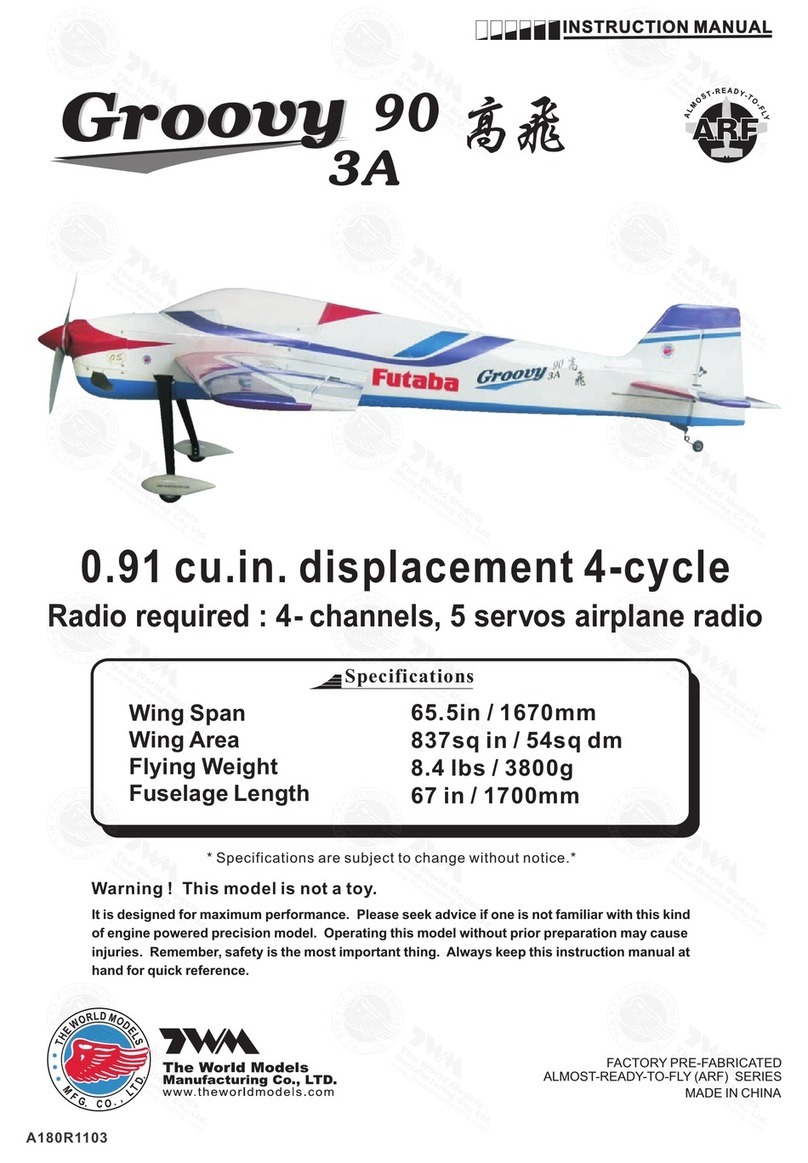

FUTABA Groovy 90 3A User manual

FUTABA

FUTABA GY501 User manual

FUTABA

FUTABA GY520 User manual

FUTABA

FUTABA G190 User manual

FUTABA

FUTABA HV BLS274SV User manual

FUTABA

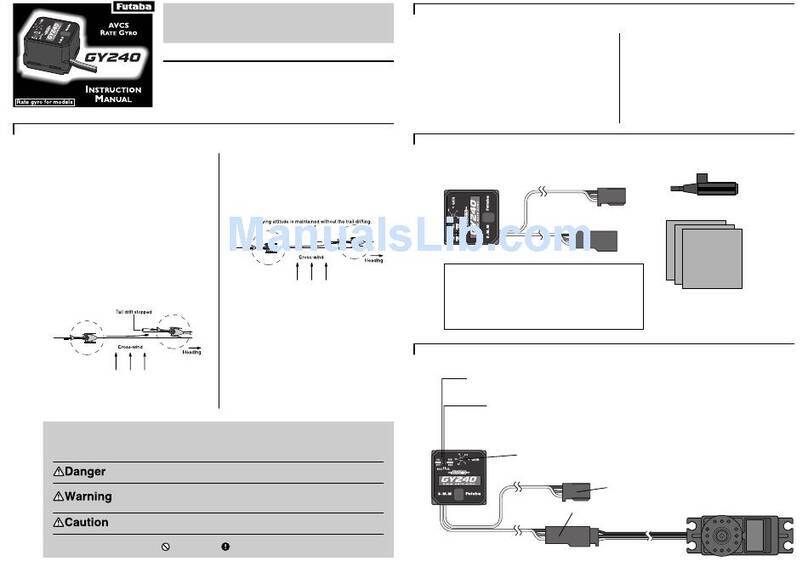

FUTABA GY240 User manual

FUTABA

FUTABA T16IZ Manual

FUTABA

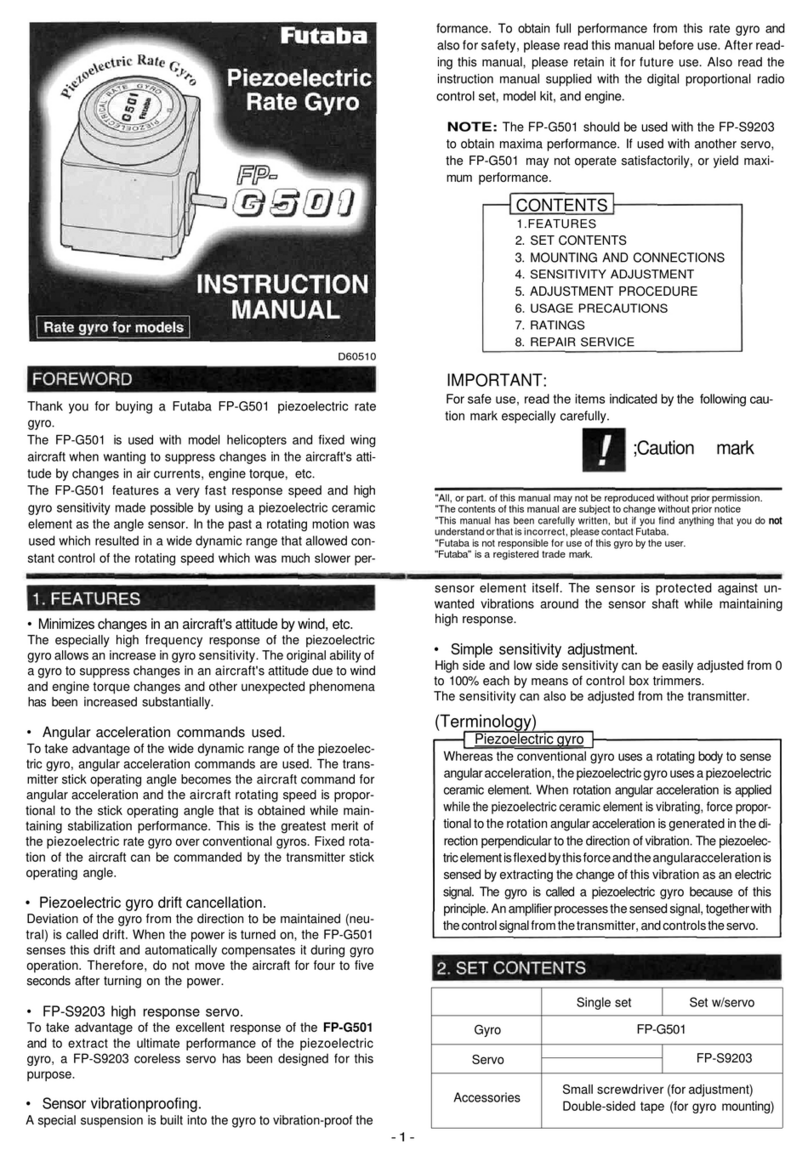

FUTABA G501 User manual

FUTABA

FUTABA GY401 User manual

FUTABA

FUTABA GY470 User manual

FUTABA

FUTABA GY601 User manual

FUTABA

FUTABA SkyLeaf-ST User manual

FUTABA

FUTABA SkyLeaf Classic User manual

FUTABA

FUTABA CGY750 User manual

FUTABA

FUTABA SkyLeaf Leader User manual

FUTABA

FUTABA Big SkyLeaf User manual

FUTABA

FUTABA Sky Leaf Samba f User manual