ACQVARIA I

TECHNICAL MANUAL4

1 MAIN FEATURES

COMFORT, LOW NOISE, AND EFFICIENCY IN PERFECT

HARMONY!

The new series of hydronic cassette units ACQVARIA, with invert-

er-controlled permanent magnet BLDC motor, consists of six

models (10-20-30-40-50-60) for 2-pipe systems and four models

(10-30-40-60) for 4-pipe systems.

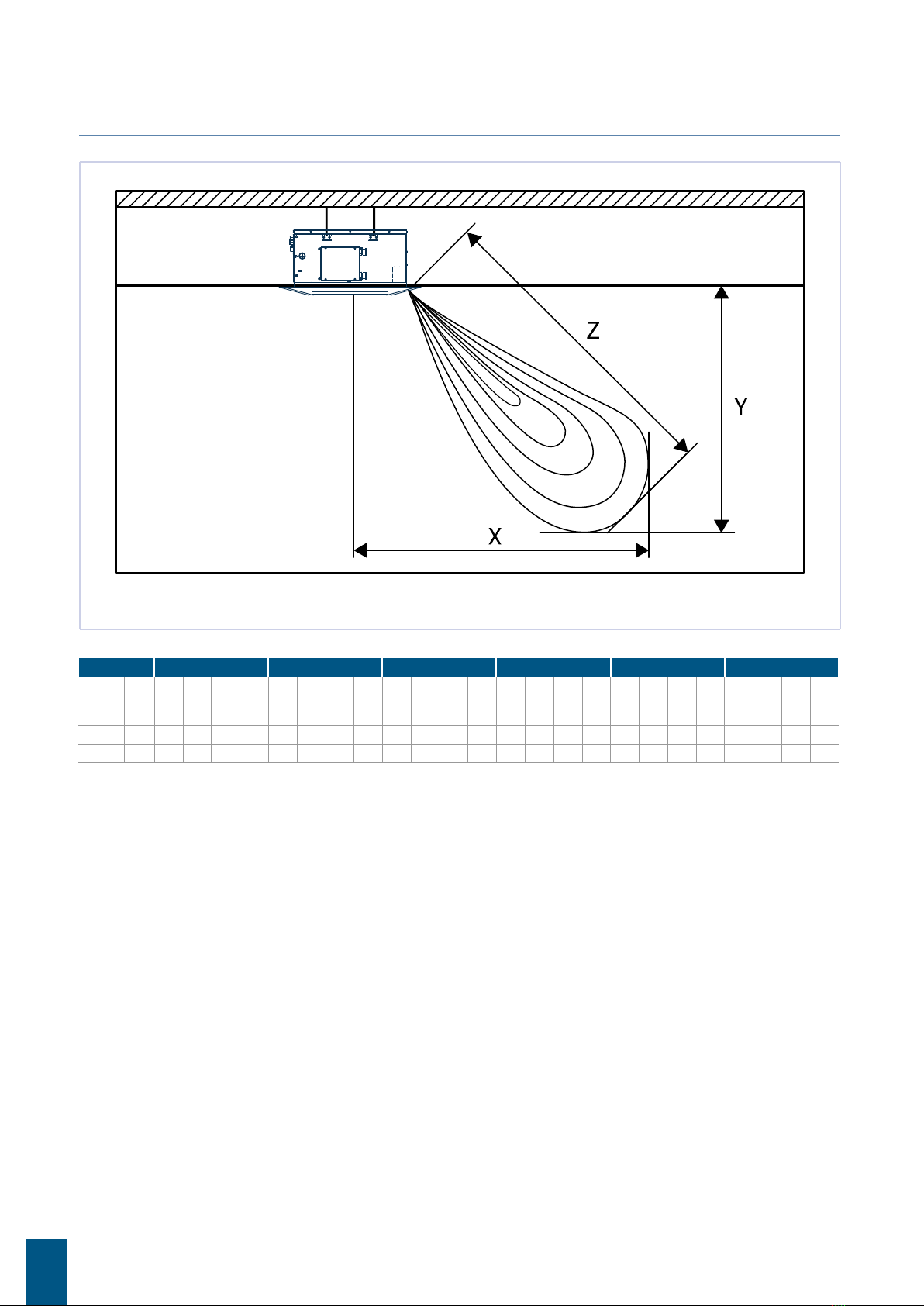

The engineering of the unit makes it possible to develop up to 5

kW in the cooling mode in a standard 600x600 mm modular sus-

pended ceiling and over 10 kW in the 860x860 mm modularity,

with exceptionally low noise levels in the phases for maintaining

interior comfort.

The well-known advantages of BLDC motors are combined with

GreenTech technology (in models 10, 20, and 30), which inte-

grates the inverter directly into the fan drive assembly.

ACQVARIA leverages the entire Galletti, MYCOMFORT, EVO , and

TED10 microprocessor controller platform that incorporate so-

phisticated adjustment logics based on air temperature, air hu-

midity, and water temperature.

These benets translate into greater accuracy in achieving and

maintaining the desired comfort conditions through appropri-

ate modulation of the fan speed as well as the reduction of noise

emissions, which adapt to the actual thermal load.

Lastly, electricity consumption is reduced by up to 75% in com-

parison to conventional xed-speed AC motors.

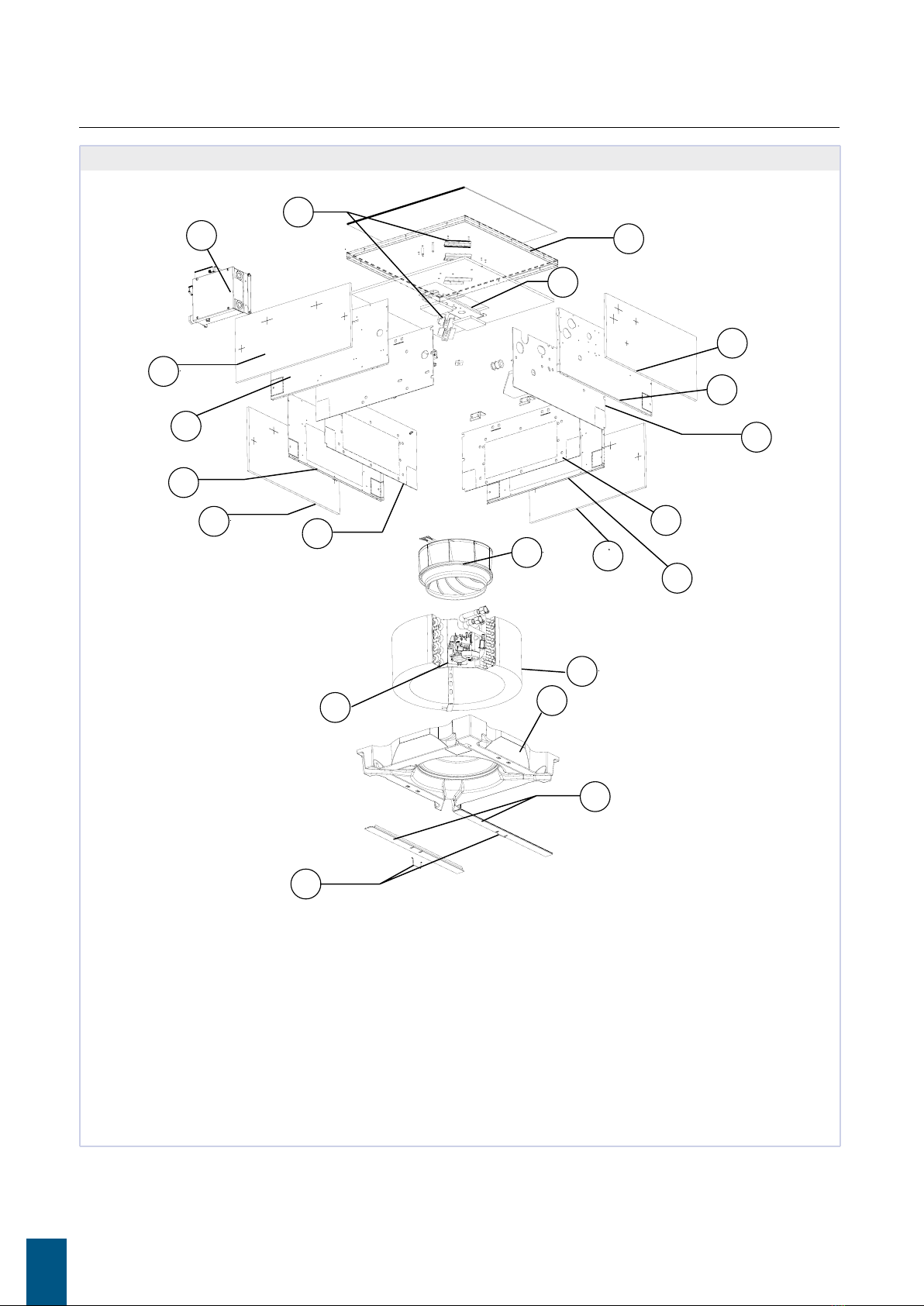

The suspended ceiling unit houses all the components, heat ex-

change coil, fan drive assembly, and condensate collection and

drainage system. Its structure is designed for introducing fresh

air into the space, mixing it with recovered air, and distributing

the treated air from the cassette unit to adjacent rooms.

The design and colour, RAL9003 or RAL9010, of the air intake

and diusion louvre guarantee optimal integration into the sus-

pended ceiling panels. Easy access to the air lter for cleaning

operations.

The unit can be supplied complete with valves, including pres-

sure-independent balancing and control valves, the use of

which signicantly reduces commissioning time.

OPERATING LIMITS

Thermal carrier uid: water

Water temperature: 5°C ÷ 70°C

Air temperature: 5°C ÷ 43°C

Supply voltage: 230 V - 50 Hz

Maximum water pressure during operation: 10 bar

Relative humidity limit of the ambient air:RH < 75% not

condensing

AVAILABLE VERSIONS

AQB0 Unit with one coil for 2-pipe systems

AQBB Unit with one coil for 4-pipe systems

Accessories supplied with the unit

Auxiliary water drip tray;

Installation and use manual;

Brackets for securing the unit.