Ganz C-AllView User manual

C-AllView

Ruggedised PTZ Camera

Installation

Manual

2

This page is intentionally blank

3

Contents

Introduction ..................................................................................................................4

Safety Warning.............................................................................................................4

Packing List..................................................................................................................4

Parts not included: ................................................................................................4

Disclaimer ....................................................................................................................4

Mounting ......................................................................................................................5

Offset Mounting ........................................................................................................6

Power Supply ...............................................................................................................6

Camera unit Composite Cable ~ RCPS1 connections .............................................7

RCPS1 System Side Connections ...........................................................................7

Telemetry Control.........................................................................................................8

On-Board Protocols ..................................................................................................8

DIL Switches.............................................................................................................8

Protocol Settings...................................................................................................9

RS485 Address Settings.......................................................................................9

RS485 Termination .............................................................................................11

Keyboard Operation ...............................................................................................11

On Screen Menu Access ...........................................................................................12

Menu Structure...........................................................................................................13

Camera On-Screen-Display ...................................................................................13

Opening screen ......................................................................................................13

Run Menu Screen...................................................................................................14

Setup Screen..........................................................................................................14

Motion Setup ..........................................................................................................16

Setting Preset Positions......................................................................................16

Editing Position Text ...........................................................................................17

Setting Preset Position Tours .............................................................................17

Programming Mimic Tours..................................................................................19

Video Setup ............................................................................................................20

Joystick Setup ........................................................................................................22

Privacy Zones.........................................................................................................23

Alarm Setup............................................................................................................25

Setting Alarm Actions..........................................................................................26

Alarm Activated Infra-Red Switching ..................................................................26

Alarm Masks .......................................................................................................27

Alarm Holidays....................................................................................................28

Display Options ......................................................................................................30

Default Position Text...........................................................................................31

Error Reporting ...................................................................................................32

Time and Date Setup ..........................................................................................33

Special Settings......................................................................................................36

Special Settings - Overview ................................................................................36

Time Out Time ....................................................................................................37

Timeout Action ....................................................................................................38

Changing the Password .........................................................................................39

Specifications .............................................................................................................41

Dimensions – Camera Unit.....................................................................................41

Dimensions – 4” PCD Adaptor ...............................................................................42

WEEE statement........................................................................................................42

Installer Notes: ...........................................................................................................43

4

Introduction

The Camera unit is designed with harsh and difficult environments in mind and to

provide enhanced features over a normal speed dome camera.

These added benefits are:

•Flat toughened glass window – scratch resistant, maintenance-free and

optically correct

•Integral Wiper – to clean away rain and deposits caused by wind, sea spray

and road traffic

•Hard anodised aluminium castings, with optional powder coating to prevent

corrosion in the harshest of marine environments

•M4 marine grade stainless steel case fastenings

•Optional Washer System

•Optional Infra Red Led illumination system

•Day night switching by external contact closure (optional alarm interface)

•Multiple native protocols - coaxial and RS485

•Optional RS485 alarm interfaces

Safety Warning

Installation of this product should only be carried our by a

competent and suitably qualified engineer. If you are in doubt,

you should refer the installation to a suitably qualified person.

Packing List

Included in the Rugged Camera kit:

1x Camera &Power-Supplyunit

1x 4”/101.6mm PCD adaptor & mounting bolts to Camera Unit

1x 10m composite cable and IP67 connector

1x Installer Manual

Parts not included:

Mounting hardware – e.g. nuts and bolts for 4” PCD adaptor to tower / bracket

Washer Nozzle & Bracket

Washer pump & Hose

Infra Red Lamps

Disclaimer

The manufacturer reserves the right to change specifications and procedures integral

to the operation, control and programming of this product at any time and without

prior notice.

This manual relates to firmware version 0.2.6

5

Mounting

The Camera unit is designed to be mounted upright or inverted. By the nature of its

manufacture, it is a heavy item, thus it requires a substantial and stable mounting.

Each Camera unit is supplied with a 4” (101.6mm) PCD mounting adaptor to allow

mounting to industry standard brackets, tower and columns.

The adaptor as two cable entry points:

1. A pass-through hole in the plate to allow cabling through a column or tube

type mounting.

2. A M25 conduit thread in the side wall to permit flexible conduit to be

connected to the adaptor.

Figure 1

This adaptor should have the composite cable threaded through it before it is

mounted to the column or bracket. The cable should be dressed such that approx

25~35mm of the weatherproof connector is protruding out of the smaller plate that

connects to the Camera unit.

Figure 2

The 4” (101.6mm) PCD plate should then be mounted to bracket or tower using M8

bolts, washers and Ny-Loc type nuts.

6

It is important that this type of nut is used to prevent injury should the bolts

work loose in operation, due to vibration.

A stainless steel wire lanyard and clip is provided as a safety measure should any of

the bolts that hold the body of the Camera unit to the adaptor bracket work loose.

Always use the lanyard to support the Camera unit during installation and

ensure that it is connected and in use when the Camera unit mounting is

complete.

Insert the connector into the socket on the Camera unit, and screw home the

retaining ring.

Push the connector back into the adaptor bracket and align

the allen head bolts with the keyhole slots.

Push the heads through the keyholes and turn the Camera

unit body so that the bolt heads drop into their respective

receptacles. The bolts should then be tightened to approx

1.6Kg/m.

Do not over tighten bolts

Figure 3

Offset Mounting

When mounting upright, an offset can be added to allow the camera field of view to

clear the pan motor section of the housing.

Unscrew and withdraw the M5

socket head retaining bolt

from the middle of the front of

the yoke.

Tip the tilt housing and yoke

assembly forward.

Re-insert the bolt from the rear

and screw home. The Torque

figure is approx 0.97Kg/m

Do not over tighten the bolt

Power Supply

The Camera unit can accept a wide range of power supply input voltages.

The applicable range is 20-36Vdc or 14-26Vac. It draws 15W peak and 5W when idle.

This however does not take account of any optional heating of cooling devices in the Camera

unit, nor optional IR lighting systems.

The RCPS1 Camera unit power supply is capable of providing sufficient current to run the

Camera unit and a 24VAC washer pump (Typical example Dennard WW5 or WW25).

This supply also has built-in transient suppression and individually fused outputs for the

Camera and Washer units, as well as spark-gap protection for video and data connections.

Each output fuse has positive indication of failure, so a blown fuse is instantly identified.

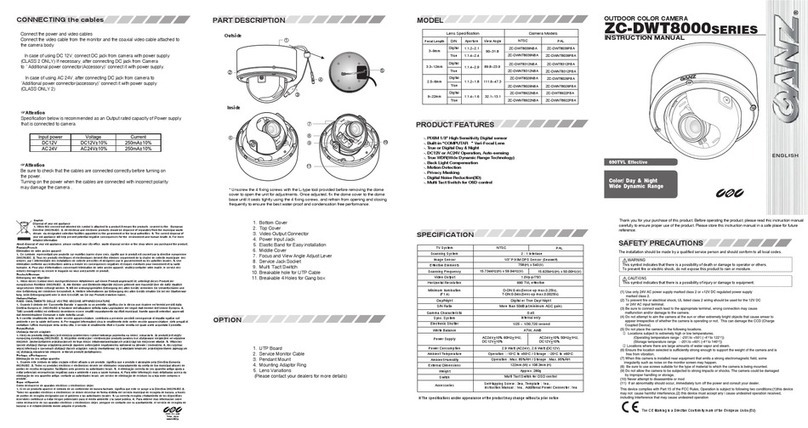

The RCPS1 pcb layout is shown below in Figure 4.

The pcb has a number of connector strips for terminations in and out of the camera plus

power output terminals and a ground lug.

Retaining

bolt

Retaining

bolt

7

Camera unit Composite Cable ~ RCPS1 connections

Connections for the Camera unit Composite cable should be made to the terminals

as follows:

URM70 Video:

Connect the centre core to the terminal marked “VIDEO”

Connect the screen to the terminal marked “GND”

Power:

Connect the Red 20AWG cable to the terminal marked PTZ 1P

Connect the Black 20AWG cable to the terminal marked PTZ 1N

Washer:

Connect one White 20AWG cable to the upper terminal marked AUX1

Connect the other White 20AWG cable to the upper terminal marked AUX2

RS485 data:

Connect the Yellow 26AWG cable to the upper terminal marked DATA 5

Connect the Blue 26AWG cable to the upper terminal marked DATA 6

Earth:

Connect the Green/Yellow cable to the Earth stud adjacent to the BNC

output socket.

The IR Lamp and Ethernet terminals are reserved for future use.

CE- RCPS1 1.0

P3

P2

P1

SLOT

2P

1P

AC IN

ON

123456

56432

1

VIDEO OUT

24V AC IN

PTZ

WASHER

1P 1N 2P 2N

MANUFACTURED IN THE E.U.

F0 F1

L1 L2

LL1

MOV1

CHOKE

7446720047 L0

R0

F2

R1

R2

R3 R4

CN0

PUMP

WASHER FEED

WASHER OUTPUT

IR LAMP +

IR LAMP -

RS485 +

RS485 -

TXD +

TXD -

RXD +

RXD -

GREEN

WHITE/

GREEN

WHITE/

ORANGE

ORANGE

ETHERNET

DATA

POWER

AUX

AUX POWER DATA ETHERNET

78910

789

10

V

GND

I

D

E

O

Figure 4

RCPS1 System Side Connections

Video:

The Video output from the RCPS1 and Camera unit is available on the pcb

mounted BNC socket. Connect the coaxial cable back to the monitor / matrix

or DVR to this socket. If the Camera unit and control system are configured to

use coax based telemetry, it will pass through this connector.

Data:

Connect RS485A (RS485+) to the lower terminal marked DATA 5

Connect RS485B (RS485-) to the lower terminal marked DATA 6

Power:

Connect 240VAC Live the to the mains input marked L

Connect 240VAC Neutral the to the mains input marked N

Connect 240VAC Earth the to the mains input marked E

8

The supplier installed mains input cable to the RCPS1 should have an isolator

fitted and be fused according to its gauge and local electrical regulations.

Failure to observe such regulations may result in injury or death

Telemetry Control

The Camera unit is designed to be added to any telemetry controlled system by

providing compatibility to a number of industry standard control protocols. This can

be done by directly using the on-board protocols or by adding a third party protocol

converter to interface between an incompatible control protocol and one of the on-

board protocols.

Telemetry control is by RS485 or Co-axial video telemetry.

Due to the limitations or software changes of the some of the protocols, it is not

always possible to implement all of the features of the Camera unit with the Original

Manufacturers protocol, thus some features on a manufacturers keyboard, may limit

the way the Camera unit can operate.

Using RS485 based telemetry camera addresses are limited to 127 addresses.

On-Board Protocols

The Camera unit has the following on board protocols:

American Dynamics / Sensormatic RS422 (uni-directional only)

BBV Coaxial Telemetry

CBC C-Dome RS485

DeView [VTC]

Kalatel DP

Overview RS485

Pelco Co-Axitron

Pelco D 2400 baud

Pelco P 4800 baud

Pelco P 9600baud

DIL Switches

All addressing and protocol selection is set by 2 banks of 8way DIL switches located

on the main body of the housing, underneath a removable weatherproof cover.

Cover retained by

two screws

Screws and cover

removed

9

Figure 5

Protocol Settings

The Protocol selection is made on Switches S1-8, S2-1, S2-2, S2-3 and S2-7

The protocol selection is defined by the following table.

Coax based protocols do not use the RS485 address, so this can be left in the

Address 0 state.

Description Protocol No. S1-8 S2-1 S2-2 S2-3 S2-7

Dennard/ Overview RS485 0 Off Off Off Off Off

Pelco P 9600 1 On Off Off Off Off

Pelco P 4800 2 Off On Off Off Off

Kalatel DP 5 On Off On Off Off

Sensormatic RS422 6 Off On On Off Off

VTC / DeView RS485 9 On Off Off

On Off

Pelco D 2400 10 Off On Off On Off

CBC C-dome RS485 12 Off Off

On On Off

Pelco Coaxitron 24 Off Off Off On On

BBV coax 31 On On On On On

Figure 6

RS485 Address Settings

RS485 address settings are set by S1-1 to S1-7 and provide binary addresses to a

camera id of 127.

S2-8 is for termination of the RS485 bus. Set to ON to enable termination at the

camera.

The camera addressing is defined as below (a “-“ indicates switch in OFF position):

Address S1-1 S1-2 S1-3 S1-4 S1-5 S1-6 S1-7 Address S1-1 S1-2 S1-3 S1-4 S1-5 S1-6 S1-7

0 - - - - - - - 64 - - - - - - ON

1 ON - - - - - - 65 ON - - - - - ON

2 - ON - - - - - 66 - ON - - - - ON

3 ON ON - - - - - 67 ON ON - - - - ON

4 - - ON - - - - 68 - - ON - - - ON

5 ON - ON - - - - 69 ON - ON - - - ON

Camera

ID number

switches

Controller

protocol

switches

RS485

Termination

10

6 - ON ON - - - - 70 - ON ON - - - ON

7 ON ON ON - - - - 71 ON ON ON - - - ON

8 - - - ON - - - 72 - - - ON - - ON

9 ON - - ON - - - 73 ON - - ON - - ON

10 - ON - ON - - - 74 - ON - ON - - ON

11 ON ON - ON - - - 75 ON ON - ON - - ON

12 - - ON ON - - - 76 - - ON ON - - ON

13 ON - ON ON - - - 77 ON - ON ON - - ON

14 - ON ON ON - - - 78 - ON ON ON - - ON

15 ON ON ON ON - - - 79 ON ON ON ON - - ON

16 - - - - ON - - 80 - - - - ON - ON

17 ON - - - ON - - 81 ON - - - ON - ON

18 - ON - - ON - - 82 - ON - - ON - ON

19 ON ON - - ON - - 83 ON ON - - ON - ON

20 - - ON - ON - - 84 - - ON - ON - ON

21 ON - ON - ON - - 85 ON - ON - ON - ON

22 - ON ON - ON - - 86 - ON ON - ON - ON

23 ON ON ON - ON - - 87 ON ON ON - ON - ON

24 - - - ON ON - - 88 - - - ON ON - ON

25 ON - - ON ON - - 89 ON - - ON ON - ON

26 - ON - ON ON - - 90 - ON - ON ON - ON

27 ON ON - ON ON - - 91 ON ON - ON ON - ON

28 - - ON ON ON - - 92 - - ON ON ON - ON

29 ON - ON ON ON - - 93 ON - ON ON ON - ON

30 - ON ON ON ON - - 94 - ON ON ON ON - ON

31 ON ON ON ON ON - - 95 ON ON ON ON ON - ON

32 - - - - - ON - 96 - - - - - ON ON

33 ON - - - - ON - 97 ON - - - - ON ON

34 - ON - - - ON - 98 - ON - - - ON ON

35 ON ON - - - ON - 99 ON ON - - - ON ON

36 - - ON - - ON - 100 - - ON - - ON ON

37 ON - ON - - ON - 101 ON - ON - - ON ON

38 - ON ON - - ON - 102 - ON ON - - ON ON

39 ON ON ON - - ON - 103 ON ON ON - - ON ON

40 - - - ON - ON - 104 - - - ON - ON ON

41 ON - - ON - ON - 105 ON - - ON - ON ON

42 - ON - ON - ON - 106 - ON - ON - ON ON

43 ON ON - ON - ON - 107 ON ON - ON - ON ON

44 - - ON ON - ON - 108 - - ON ON - ON ON

45 ON - ON ON - ON - 109 ON - ON ON - ON ON

46 - ON ON ON - ON - 110 - ON ON ON - ON ON

47 ON ON ON ON - ON - 111 ON ON ON ON - ON ON

48 - - - - ON ON - 112 - - - - ON ON ON

49 ON - - - ON ON - 113 ON - - - ON ON ON

50 - ON - - ON ON - 114 - ON - - ON ON ON

51 ON ON - - ON ON - 115 ON ON - - ON ON ON

52 - - ON - ON ON - 116 - - ON - ON ON ON

53 ON - ON - ON ON - 117 ON - ON - ON ON ON

54 - ON ON - ON ON - 118 - ON ON - ON ON ON

55 ON ON ON - ON ON - 119 ON ON ON - ON ON ON

56 - - - ON ON ON - 120 - - - ON ON ON ON

57 ON - - ON ON ON - 121 ON - - ON ON ON ON

11

58 - ON - ON ON ON - 122 - ON - ON ON ON ON

59 ON ON - ON ON ON - 123 ON ON - ON ON ON ON

60 - - ON ON ON ON - 124 - - ON ON ON ON ON

61 ON - ON ON ON ON - 125 ON - ON ON ON ON ON

62 - ON ON ON ON ON - 126 - ON ON ON ON ON ON

63 ON ON ON ON ON ON - 127 ON ON ON ON ON ON ON

Figure 7

RS485 Termination

If the Camera unit is installed using a RS485 based control system, care needs to

taken to ensure the RS485 bus is terminated properly to prevent erratic operation.

The maximum length of cable that be used on one cable section in 1.2Km. There is a

maximum number of 32 devices that can reside on a cable section. All devices must

be un-terminated, with the exception of the last unit which must have its RS485

termination set to ON (S2-8 ON)

CAT5 cable or any cable that meets or exceeds the requirements for EIA RS485 may

be used for RS485 telemetry control

Figure 11

Keyboard Operation

Where possible, manufacturer key sequences have been implemented to make the

control of the camera unit as close as possible to the “normal” telemetry system

implemented by the OEM manufacturer, i.e. presets and tours can be programmed

and recalled in the same way from the manufacturers control system.

Where it has not been possible to implement all of the Camera unit features with a

manufacturer’s protocol, the extra features can be accessed through the camera unit

on-screen-menu.

Note – OE manufacturers may update software or protocols in their keyboards

without prior warning, This may change the way in which the Camera unit behaves in

relation to keyboard operation. The manufacturer accepts no responsibility for such

changes in OE Manufacturer software/protocols.

Un

-

Terminated

Terminated

12

On Screen Menu Access

Using the following sequences, the Camera unit OSD menu can be accessed. The

MENU sequence will open the OSD and the SELECT sequence will accept the

current data displayed.

Overview

Menu: Recall Preset 94

Select: Recall Preset 1

Pelco (All types)

Menu: Store preset 95

Select: Iris Open or Recall Preset 1

DeView

Menu: ENT (to open) / ESC (to exit)

Select: ENT

CBC C-Dome (RS485)

Menu: Recall Preset 95

Select: Recall Preset 1

American Dynamics / Sensormatic RS422

Menu: Recall / Store Preset 94

Select: Recall Preset 0

Kalatel

Menu: Recall / Store preset 64 or Menu

Select: Recall Preset 0

BBV TX400 (Coax)

Menu: Shift (or #) + 1

Select: Recall Preset 1

BBV TX1000

Menu: Shift + Wash

Select: Recall Preset 1

BBV TX1500

Menu: 1 then #

Select: Recall Preset 1

Dedicated Micros DS/BX range:

Menu: * 8 8 9 10 10 2 or ** (depending on S/W version)

Select: Recall Preset 1

13

Menu Structure

Camera On-Screen-Display

Opening screen

Start up screen

Selecting RUN from the MAIN MENU allows a user to go to a pre-set

position or start a tour. There are 32 pre-set positions, 8 slow tours (S), 8

fast tours (F) and 4 one-minute mimic (M) tours. When a programmed

position or tour is selected the menu will be cleared from the screen and

the unit will execute the appropriate function.

In this guide the yellow

border indicates the

item is flashing

This arrow confirms

the item selection and

returns the user to the

a

pp

ro

p

riate menu

Selecting the arrow will

take the user to the

previous screen

This arrow deletes the

last item selected by

the user

14

Run Menu Screen RUN menu screen

If a position or tour is not set a message will be displayed, POSITION NOT SET

or TOUR NOT SET, respectively. WASH moves the unit to the wash position, if it

has been set, and starts the screen wash process. WIPE activates the wiper for 5

seconds.

Setup Screen Start up screen

The SETUP menu gives the operator full access to set up presets and

tours as well as other features of the unit. SETUP menu is password

protected

15

SETUP first screen – Password menu

The default password is “AAAAAA”; once entered 6 stars displays on the

screen and the SETUP menu appears. If the PASSWORD menu is re-

displayed it means the incorrect password has been entered.

When the correct password is entered, the following screen is shown:

SETUP menu screen

Selecting any of the above options will then reveal sub-menus relative to

the chosen option

16

Motion Setup

Setting Preset Positions

Once the password is correctly entered, the above screen is displayed.

Selecting MOTION from SETUP menu allows an operator to set up preset

positions and tours: MOTION Menu Screen

Selecting a position takes the operator to the FORMAT POSITION menu.

FORMAT POSITION menu screen

The FORMAT POSITION menu allows the operator to setup a preset

position. The top line of this menu displays the position number and its

status. STORE CURRENT VIEW sets the current unit view to the

currently selected position number. GOTO POSITION leaves the menu

structure and moves the unit to the position. EDIT POSITION TEXT

17

takes the operator to the EDIT POSITION TEXT menu. DELETE

POSITION removes the position and resets its status.

Editing Position Text EDIT POSITION menu screen

In the EDIT POSITION TEXT menu custom text can be entered which

will be displayed on the screen when at the position.

NOTE: GOTO POSITION, EDIT DEFAULT TEXT and DELETE POSITION

will only function if the position has been set.

Setting Preset Position Tours

MOTION Menu screen

Selecting a slow (SX) or fast (FX) tour from the MOTION menu takes the

operator to the SETUP TOUR menu. A slow tour has a dwell time of 6

18

seconds and travel time between positions of 10 seconds. A fast tour has

a dwell time of 6 seconds and a travel time between positions of 1 second.

SETUP TOUR menu screen

EDIT TOUR takes the operator the to the EDIT TOUR menu. SETUP

TOUR menu displays the selected tour and its status. START TOUR will

exit the menu structure and execute the currently selected tour. DELETE

TOUR will delete the currently selected tour.

NOTE: START TOUR and DELETE TOUR will only function if the selected

tour has been set.

EDIT TOUR menu screen

In the EDIT TOUR menu, the tour can be setup by selecting the positions

wanted for that tour. Each tour can contain up to 8 positions. Selecting

the forward arrow Xconfirms the new tour setup, whereas the backward

arrow Wdeletes the last position from the tour.

19

Programming Mimic Tours

First selecting the MOTION option from the SETUP menu and the

following screen is displayed:

MOTION menu screen

Selecting a mimic (MX) tour from the MOTION menu takes the operator

to the SETUP MIMIC TOUR menu.

SETUP MIMIC TOUR menu screen

The top line of the SETUP MIMIC TOUR menu displays the currently

selected mimic tour and its status. RECORD NEW MIMIC TOUR takes

the operator to the RECORD MIMIC TOUR screen. START TOUR leaves

the menu structure and starts the currently selected mimic tour. DELETE

TOUR deletes the currently selected mimic tour.

20

RECORD NEW MIMIC TOUR menu screen

After selecting RECORD NEW MIMIC TOUR the unit can be moved to the

starting position of the tour, and recording started by pressing the

SELECT button. If the operator cancels the recording they are taken back

to normal joystick operation.

Video Setup SETUP menu screen

Selecting VIDEO from the SETUP menu takes the operator to the VIDEO

SETTINGS menu.

Other manuals for C-AllView

1

Table of contents

Other Ganz Security Camera manuals

Ganz

Ganz ZN-D2MAP User manual

Ganz

Ganz ZC-DW4039 NHA User manual

Ganz

Ganz ZC-BNX8312NBA User manual

Ganz

Ganz ZC-D4000 Series User manual

Ganz

Ganz ZN-PTZ202XE User manual

Ganz

Ganz ZN-PTZ202XE-XT User manual

Ganz

Ganz ZC-Y41PH3 User manual

Ganz

Ganz ZN-CM1 User manual

Ganz

Ganz ZC-DWNT8312NBA User manual

Ganz

Ganz ZN1-D4FN7 User manual

Ganz

Ganz ZC-PT336N-IR User manual

Ganz

Ganz ZC-PT series User manual

Ganz

Ganz ZC-Y20PH User manual

Ganz

Ganz ZC-DN3048PHA User manual

Ganz

Ganz ZN-BT3312 User manual

Ganz

Ganz DAY/NIGHT VANDAL DOME CAMERA User manual

Ganz

Ganz ZN-M2AF User manual

Ganz

Ganz ZN-PTZ12VP-XT User manual

Ganz

Ganz PIXELPRO SERIES User manual

Ganz

Ganz BC-IR3.6N User manual