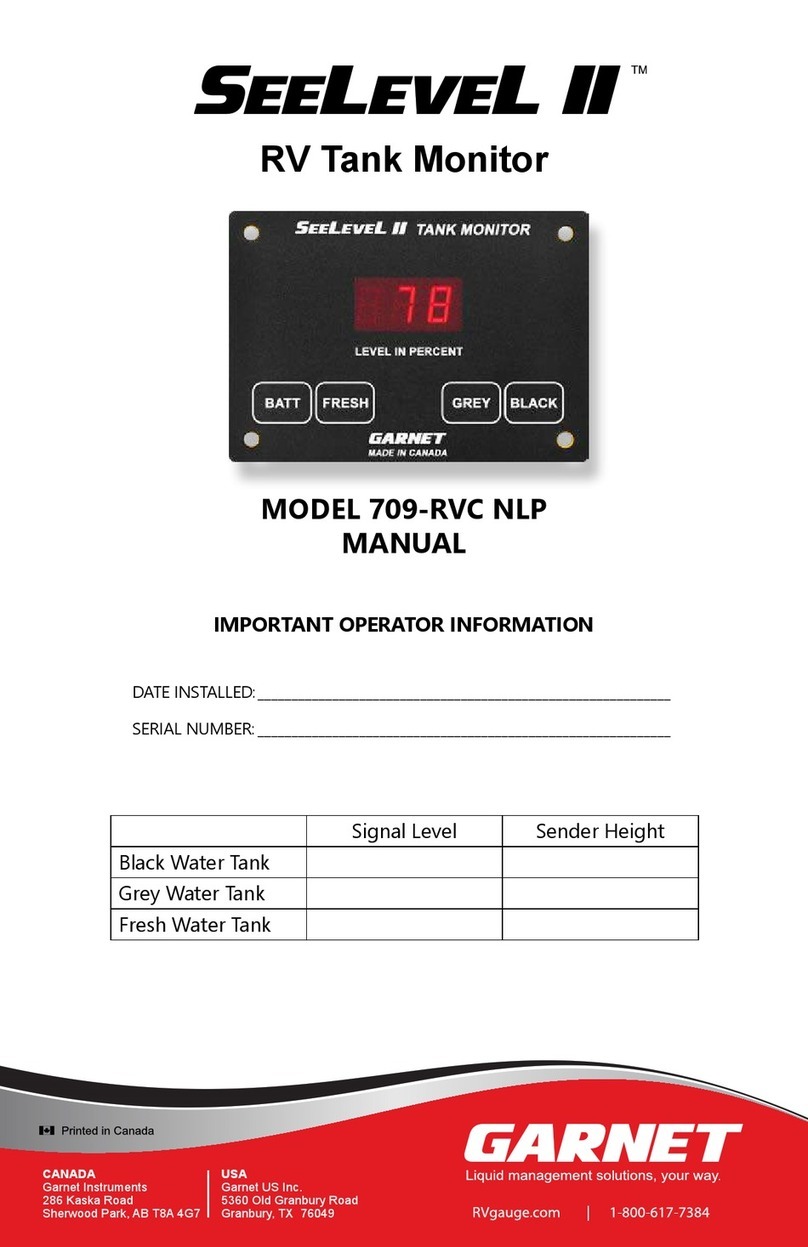

Page 20 709-N2K NLP/709-N2KP NLP Manual

7.

be cut is the bottom end, which is the opposite end from the top

8. The senders need to be programmed so they know which tank

on the top of the sender. See the chapter entitled “SENDER

PROGRAMMING” for details.

9. For double stacked sender systems, the senders also need to

be programmed so they know whether they are being used

as top or bottom senders. See the chapter entitled “SENDER

PROGRAMMING” for details.

10. Once the sender is cut to length and programmed, do a test

by taping the sender to the tank wall. Make sure there are no

air gaps between the sender and the tank. Verify operation

before permanently sticking the sender to the tank wall. Once

paper from ripping. Be careful not to bend the sender sharply

in the process. Position the sender over the side of the tank and

carefully stick it down.

Position the bottom of the sender at least ¼” above the bottom

of the tank, or slightly higher if required to equalize the space

at the top and bottom of the tank. Make sure that the sender is

square with the tank. You only have one shot at this, if you try to

by the sharp bending. Carefully press the sender down to the

tank so that all of the adhesive is contacting the tank wall.

11. Do steps 5 to 10 for the other two holding tanks.

12. Connect all the blue wires from the senders together, and to the

blue wire from the display. Connect the black wire from each

sender to ground at the display. It is very important that the

display and the senders have the same ground. Use crimp on

butt connectors to fasten the wires together.

WCAUTION: DO NOT cut the sides, and DO NOT cut the 710ES

sender shorter than 4 ½”. The cut must be in between the sensor

pads, and the cut must be made parallel to the existing bottom

end. Double check your measurements, if the sender is cut too

short, it cannot be lengthened.

W CAUTION: Make sure that the end with wires is pointing up!!