REFERENCE PRINT

SERVICE MANUAL

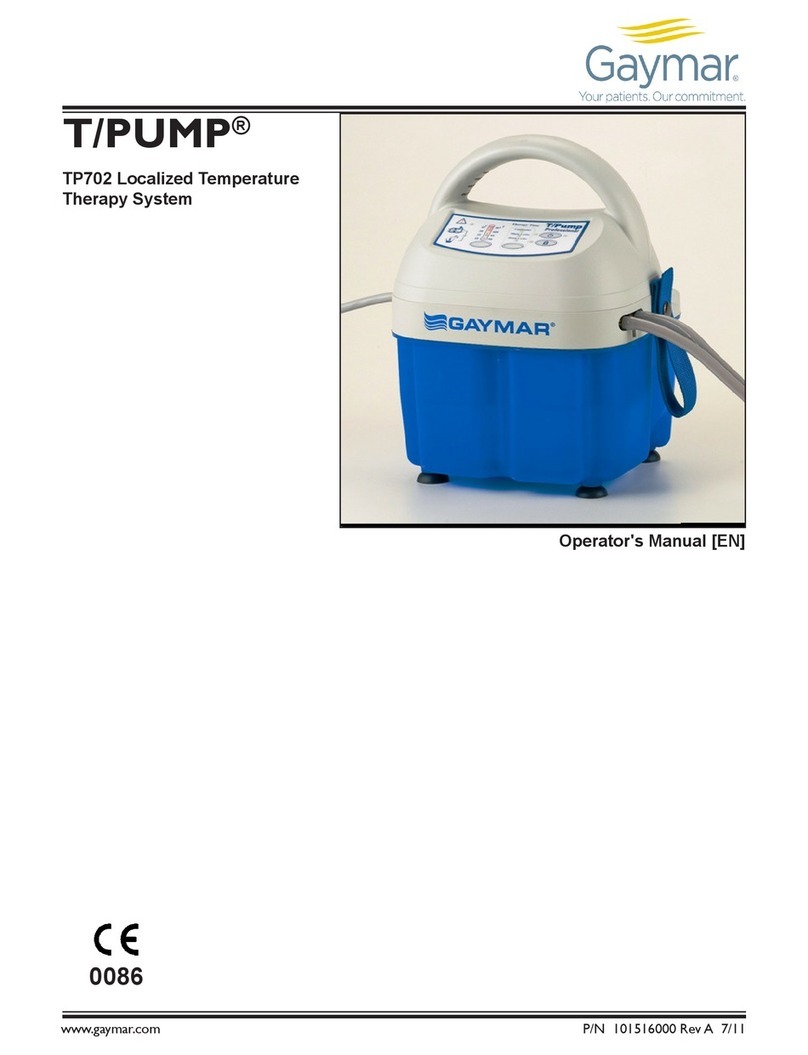

T/PUMP (TP400 Series)

7

Disconnect pad. Connect ends of the connector hoses together. Open

hose clamps. Leave water in the reservoir. To prevent hose kinks, coil the

hose rather than folding it. Fasten the hose and cord with strap.

Disconnect pad. Connect ends of the connector hose together. Open hose

clamps. Add 1/4 ounce AirKem A-33, GAYMAR MTA33 germicidal or

equivalent to water already in reservoir. Run for two (2) minutes. Drain

pump. To prevent hose kinks, coil the hose rather than folding it. Fasten

the hose and cord with strap and store pump.

Unplug the power cord. Disconnect the pad or hoses from one another,

keeping hoses at or above the level of the T/Pump. Remove the fill cap and

invert the T/Pump over a sink. When all fluid has drained from the hoses

and reservoir, replace the fill cap and connect the hoses together.

Unplug the power cord.

To clean the external surfaces, use a non-abrasive cleaning solution (such

as warm, soapy water) and a damp cloth.

To clean the fluid system, drain the pump. Fill the reservoir to the operat-

ing level indicated on the side of the pump. Add 1/4 ounce GAYMAR

catalog MTA33 germicidal or equivalent. Set the temperature indicator to

its lowest setting (fully counterclockwise). Start the

T/Pump and circulate the solution for one hour. Drain the solution and

refill the pump with distilled water. Using distilled water retards algae

growth and mineral buildup.

Change the distilled water monthly or more often depending upon use.

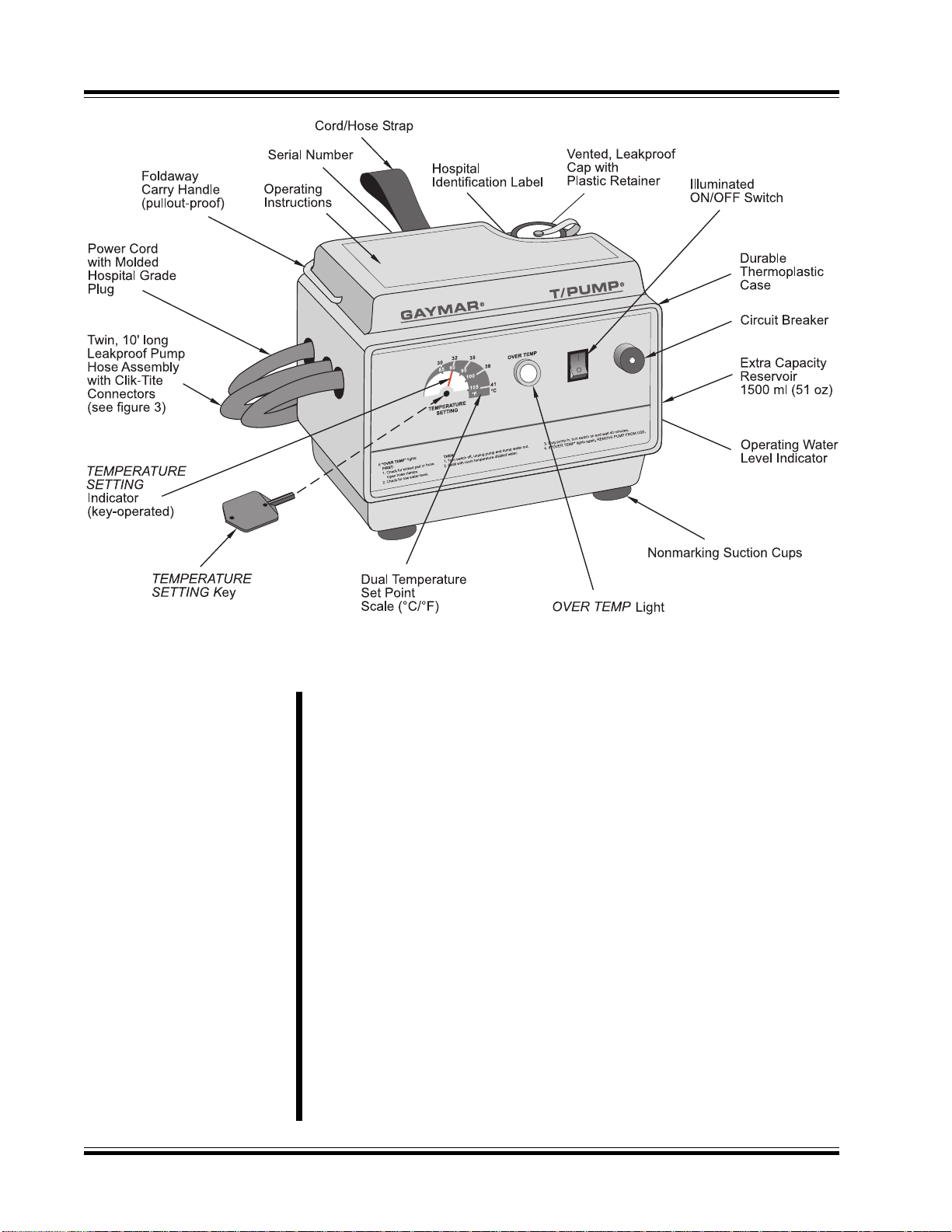

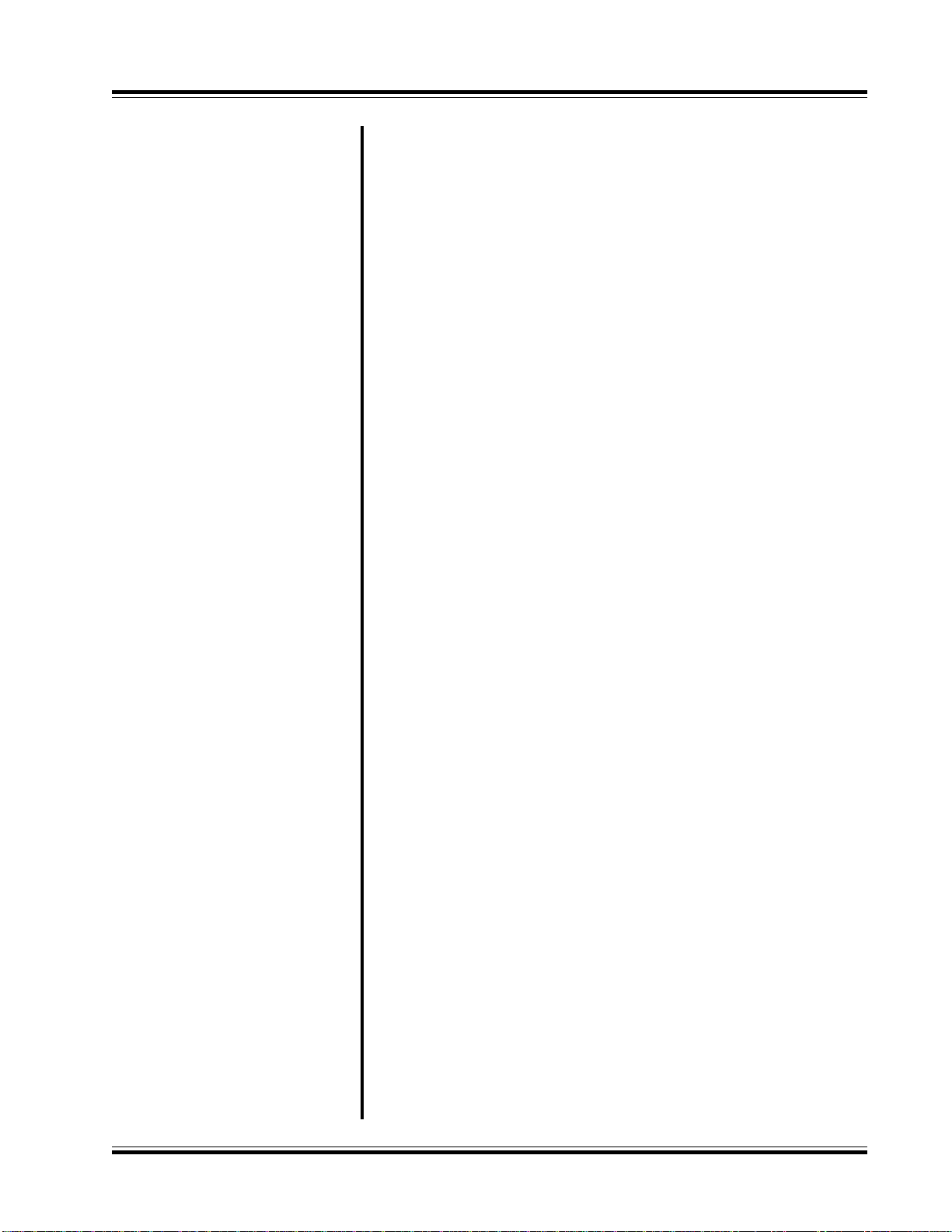

For best results use only GAYMAR T/Pads®or Mul••T••Pads®. The unique

button design allows water to flow and provides trouble free operation

when the pad is folded. This reduces the number of different sizes of pads

your facility must keep in inventory. The T/Pads can be interconnected to

provide therapy to more than one body site at a time (see fig. 1, p. 3). For

a brochure listing the various T/Pads, contact the GAYMAR Customer

Service Department (see inside cover for telephone numbers).

An optional bed bracket (model TP20A) is available to mount the T/Pump

on the footboard of a bed.

Storage (Short term)

Storage (Long term)

Draining

Cleaning

Pads / Accessories

STORAGE/CLEANING

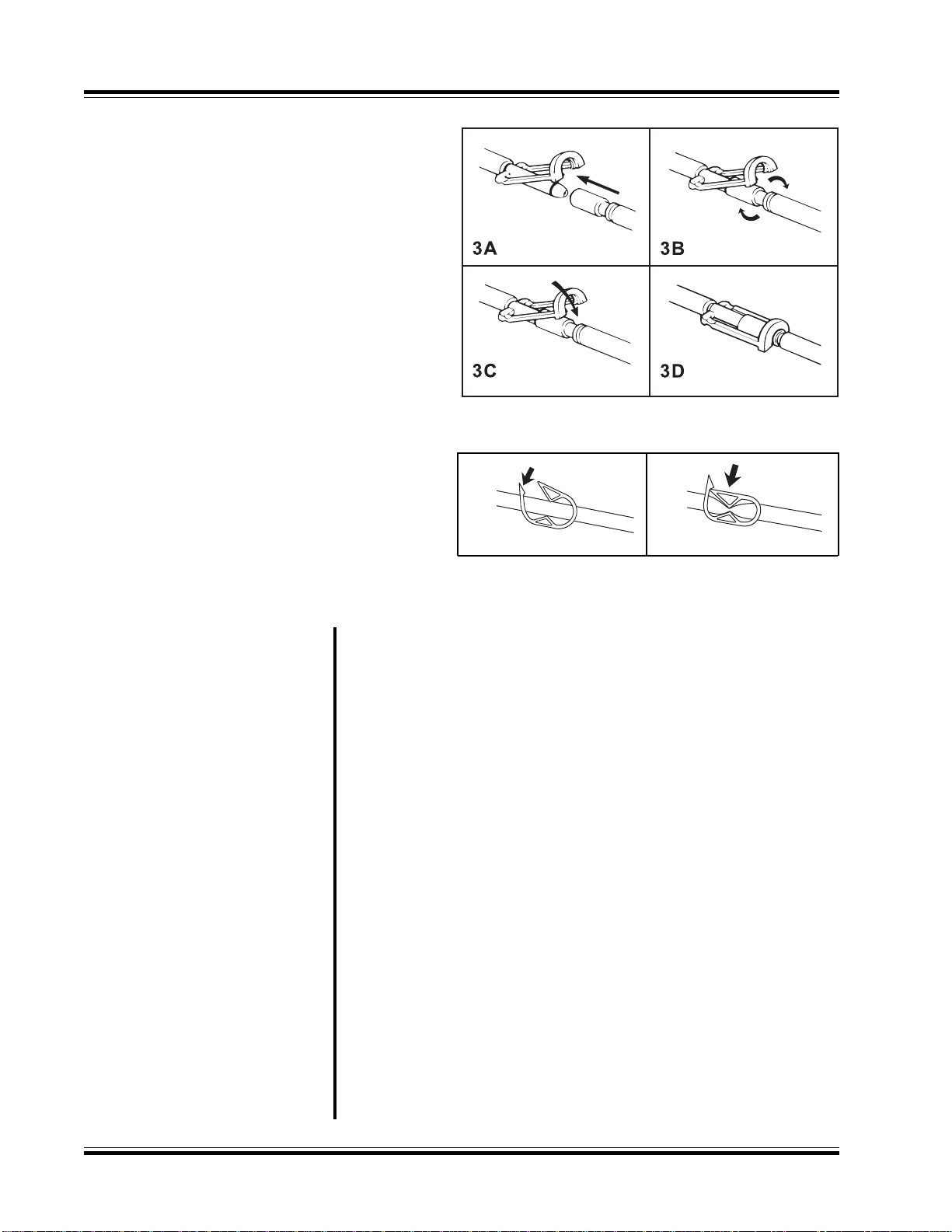

SHUTDOWN PROCEDURE 1. Turn off pump before disconnecting pad. Close hose clamps. To

prevent water spillage, always disconnect pad from pump with

connectors raised above the level of the pad and pump.

2. Connect the T/Pad Clik-Tite connectors together.

3. Connect the ends of the T/Pump connector hose together.

STORAGE AND CLEANING