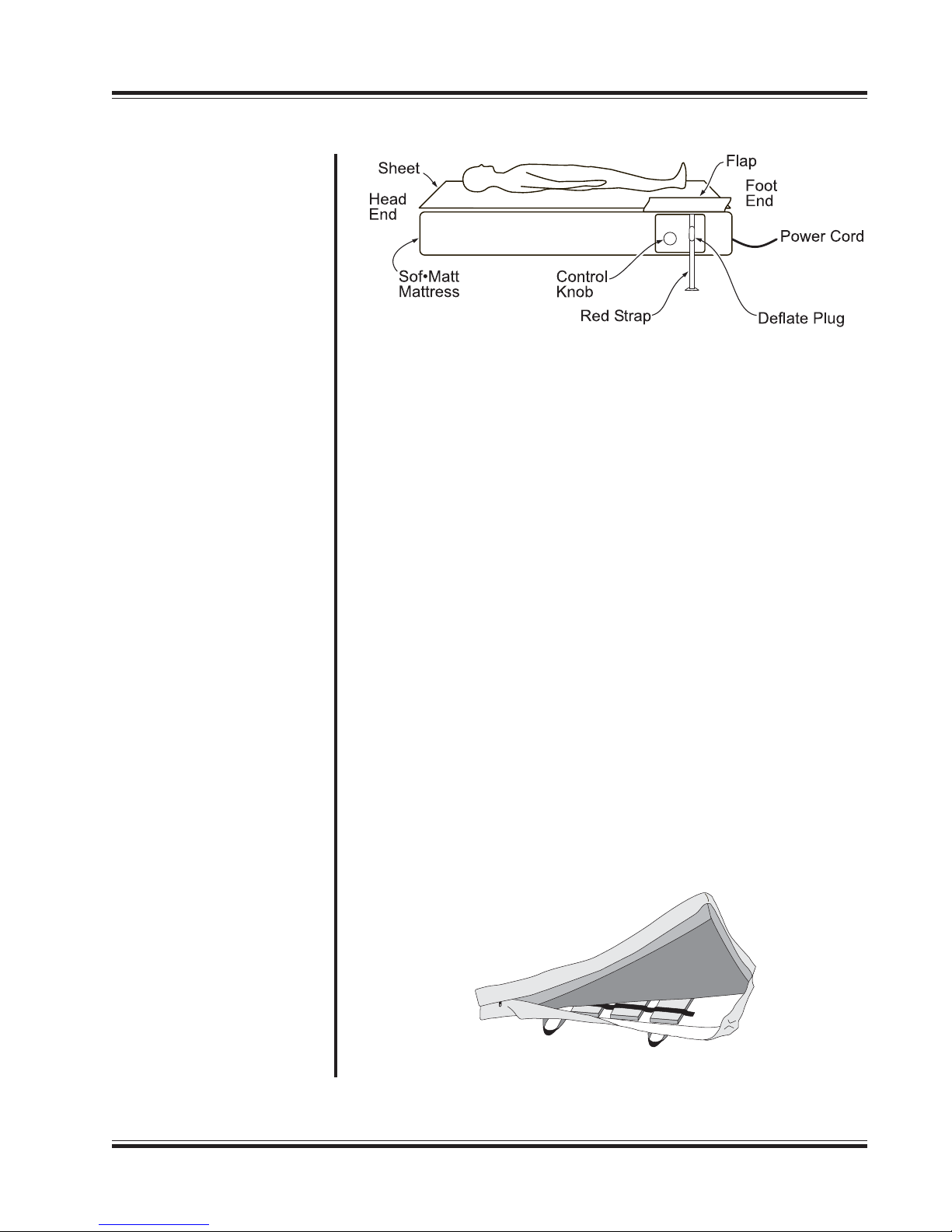

Sof•Matt®Low Air Loss Mattress System

Operator's/Service Manual

Gaymar and Sof•Matt are registered in the U. S. Patent and Trademark Office.

© 2001. Gaymar Industries, Inc. All rights reserved. www.gaymar.com

Before you begin . . .

WARRANTY

Sof•Matt Low Air Loss Mattress Systems are

warranted against defects in material and

workmanship under normal use and operation from

the date of shipment for a period of one year.

During the warranty period, Gaymar will repair or

replace at its sole option, free of charge, any

defective parts or products returned with prior

authorization prepaid to Gaymar Industries, Inc.

See Incoming Inspection and Return Policy.

Warranty does not cover products abused, misused,

or altered outside factory. There are no obligations

on the part of Gaymar for consequential damages

arising out of or in connection with the use or

performance of the product. Gaymar disclaims all

implied warranties including, but not limited to, the

implied warranties of merchantability and of fitness

for a particular purpose.

APPLICABLE SERIAL NUMBERS

This service manual applies only to models RSM176S

(no configuration) and RSM180S configuration ‘A’

Sof•Matt Mattress Systems. The 8th character

of the serial number identifies the configuration.

For example, S/N RSM180S A B10042

identifies a configuration ‘A’ system.

IMPORTANT

Please read all precautions and instructions before

using the Sof•Matt®Low Air Loss Mattress System.

Maximum benefit to the patient at the greatest margin

of safety requires a thorough knowledge and

understanding of the correct operation and

application of the Sof•Matt Low Air Loss Mattress

System.

Users must follow the instructions and precautions

included with each mattress system prior to use.

Operate the equipment with the same care you

would use when operating precision medical

equipment.

INCOMING INSPECTION AND

RETURN POLICY

Check the shipping carton for damage immediately

after receipt. If damage is discovered, the product

should be unpacked with the carrier’s agent present.

Make a claim immediately to the carrier for the damage.

Do not return damaged goods without notifying the

carrier. If products damaged during shipment are

returned to Gaymar without notifying the carrier,

Gaymar will assume that repairs will be made at the

customer’s expense. Products returned to Gaymar

must be accompanied by Returned Goods (RG)

numbers. Returned Goods authorization and numbers

may be obtained by calling Gaymar Industries'

Customer Service Department:

Toll free: 1 800 828-7341

Direct: (716) 662-2551

When inquiring, please supply model and serial number,

purchase order number, whether merchandise was

bought on contract, and reason for return.

In general, deleted and outdated merchandise will not

be accepted for credit. A restocking charge of 15% will

be assessed on returns of current merchandise.

Ship returns prepaid to Gaymar Industries, Inc.,

10 Centre Drive, Orchard Park, NY 14127-2295.

Sof•Matt Low Air Loss Mattress Systems purchased by

individuals for home use must be returned to the

dealer from which they were purchased for repair.

SYMBOLS USED

Attention: consult accompanying documents

Dangerous voltage

Double insulated. When servicing, use only

identical replacement parts.

Type BF applied equipment

Pull red strap to rapidly deflate

mattress for performing CPR