60 Hertz 115-

120V

200-

208V

230-

240V ---- 460-

480V

575-

600V

50 Hertz 110 ----- 220V 380V 440V 550V

Coil Suffix 002 023 003 064 004 005

Quantity Require

CR301/CR311/CR390

Ref.No

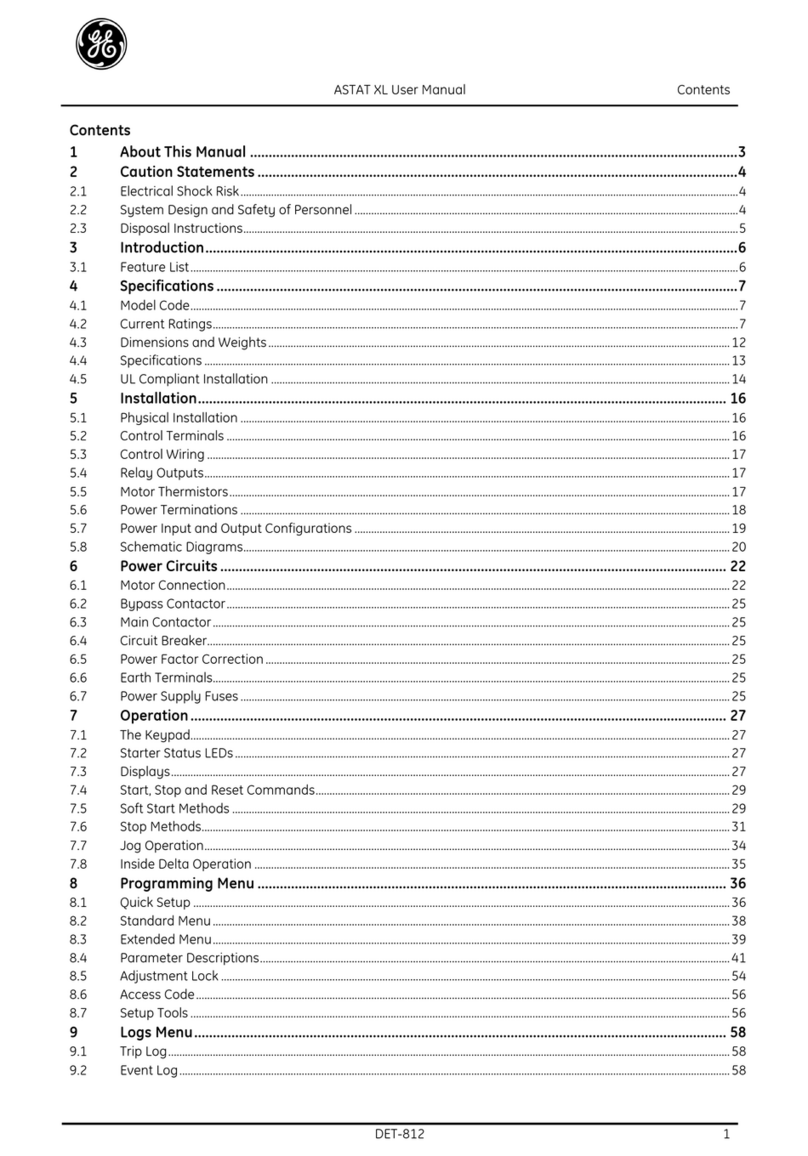

Figure.4 Description Catalog

Number CR307/CR308/

CR387

1

2

3

4

5

6

7

8

9

10

11

12

Coil retainer assembly

Overloa relay (3-heater, non-compensate form, 1 NC contact)

Overloa relay (3-heater, non-compensate , 1 NO-1 NC contacts)

Set of stationary an movable contacts with springs an screws for four poles:

NEMA Size 0

NEMA Size 1

Mol e cover for stationary an movable contacts

Return spring for movable contact support

Mol e movable contact support for 2-, 3-, 4- pole

Armature an frame (magnet)

Operating coil

Spring retainer for armature

Overloa relay for 2-spee single-win ing controller (1 NC contact)

Overloa relay for 2-spee single-win ing controller (1 NO-1 NC contact)

546A301G050

CR324C310F

CR324C360F

---------------

546A300G002

546A301G053

188D711P001

541A278P001

187D350P001

546A301G054

15D21G***

546A588P001

CR324C310G

CR324C360G

2

1

1

-

1

1

1

1

1

1

1

1

-

-

2

1+

1+

-

1

1

1

1

1

1

1

1

1

1

2

++

++

-

1

1

1

1

1

1

1

1

-

-

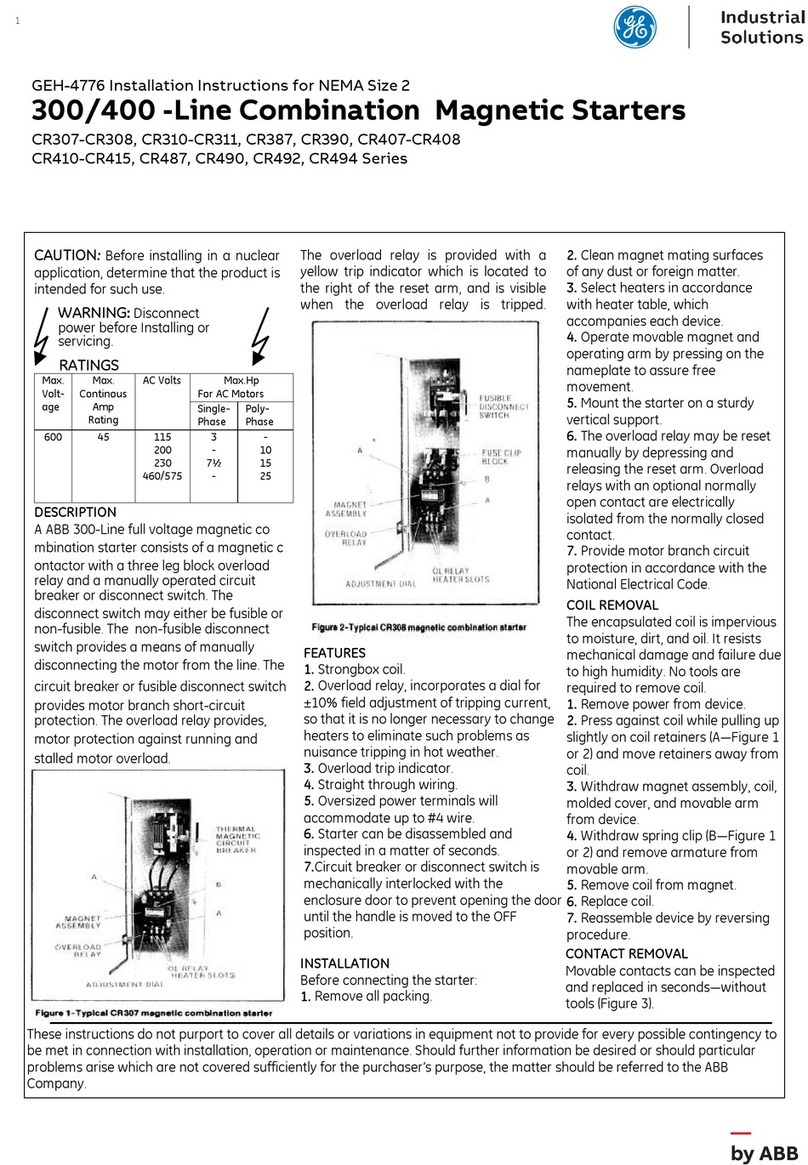

In this con ition there shoul be continuity

between the terminals. Depress white manual

check operator to trip the relay. In the trippe

con ition the circuit between the terminals

shoul be open in icating the contacts are

operating normally. Rewire the terminals an

reset the relay for normal operation

1. Always remove power from evice before

performing any maintenance.

2. Keep magnet mating surface free of

accumulate irt or ust.

3. Do Not Oil Or Grease the magnet mating

surfaces.

4. Contacts are carefully esigne for

maximum life. They nee only be replace

when nearly all the silver tip is gone an the

contact tip support is expose . Do Not File the

contacts. Filing or ressing the contacts only

results in lost tip material an re uces life.

5.

The ultimate tripping current of the installe

relay heater can be a juste ± 10% by using

the a justment ial, shown in Figure 1.

Before adjusting or operating reverser,

make sure the mechanical interlock arm is

engaged with movable contact arm.

mechanical interlock has been factory a juste an

normally shoul never have to be rea juste . If

rea justment is ever nee e , these steps shoul be

followe :

A. Close one contactor by han by pushing own on

armature.

B. Using the other han , loosen the nut on opposite

contactor interlock arm an sli e it towar s the top

of the elongate slot until all gap is taken up

between the two arms. Follow the same proce ure

with the opposite contactor an interlock arm.

C. Best a justment is usually obtaine when both

mechanical interlock arm assemblies are as far up in

the elongate slot as possible.

D. With both arms a juste , there shoul be a very

slight gap (approximately 1/16- inch) between the

arms with both contactors open. Neither arm shoul

overlap the other with both contactors open.

(Or er 15D21G plus coil suffix number below)

First NO aux. cont.for CR305, CR306…………CR3O5X100A

First NC aux. cont. for CR305, CR306…………CR3O5X100B

First NO-NC aux. cont.for CR305, CR306.. .CR3O5X100C

A itional NO aux. cont. for all forms. . … CR3O5X100D

A itional NC aux. cont. for all forms . . .. CR3O5X100E

Pushbutton………………………………………………….. CR305X120N

Selector switch, H—O—A. ………………………… CR305X130N

Selector switch, OFF—ON. ……………………… CR305X130P

In icating light. ………………………………………… CR305X150N

Fifth pole. …………………………………………………… CR3O5X111B

Control circuit fuse………………………………….. CR305X141A, B, C, D

General Electric Company

41 Woo for Avenue, Plainville, CT 06062

GEH-5193B 08/10, 10-2049 © 2010 General Electric

Visit us on the web at www.Gein ustrial.com

*** A coil suffix number from above table to complete the catalog number. Example: Cat. No. 15D21GO02 has ratings of 115—120V, 60 Hz an 11OV, 50 Hz.

+Omitte on 2-spee single-win ing controller.

++ Quantity one for multi-spee controller.

These instructions o not purport to cover all etails or variations in equipment not to provi e for every possible contingency to

be met in connection with installation, operation or maintenance. Shoul further information be esire or shoul particular

problems arise which are not covere sufficiently for the purchaser’s purpose, the matter shoul be referre to the GE Company.