BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 7

October 1998

Function 4 and Function 8 of the Handset. The C/L setting is

based on the maximum thermal rating of the control.

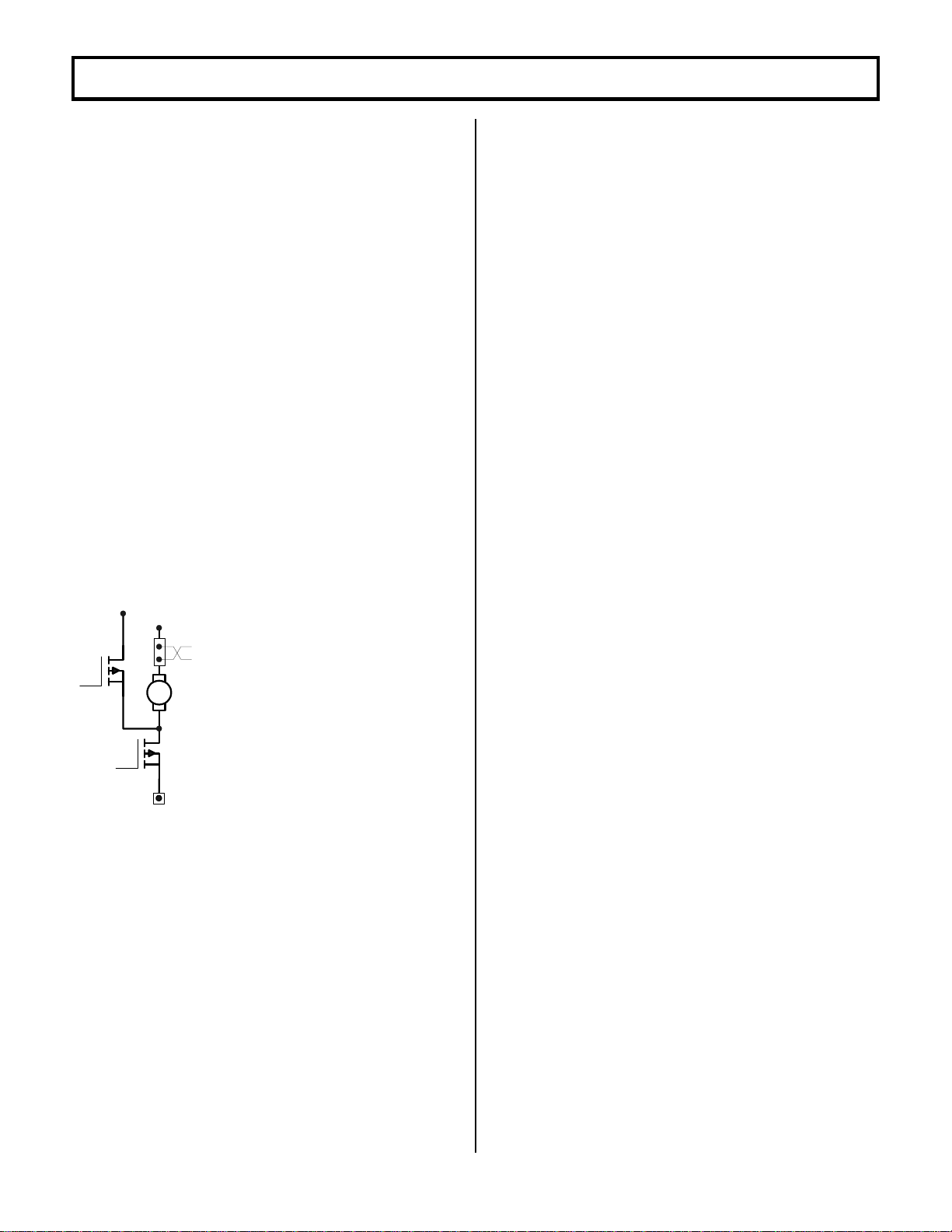

Because of the flyback current through 3REC, the motor

current isusually greater than battery current, exceptat

100% ON time, or when the lA contactor is closed.

Section 2.1.3 Braking

Section 2.1.3.a Plug Braking

Slow down is accomplished when reversing direction by

providing a small amount of retarding torque for

deceleration. If the vehicle is moving, and the directional

lever ismoved from one direction to the other, theplug

signal is initiated. Once the plug signal has been initiated,

the field is reversed, and the armature current is regulated

to the plug currentlimit as setby Function 6. Armature

current is regulated by increasing the field current as the

vehicle slows down. Once the field current reaches a

preset value, set by Function 10, and armature plug current

can no longer be maintained, the braking function is

canceled, and the control reverts back to motoring.

All energy produced by themotor during plugging is

dumped as heatin the motor in this braking mode.

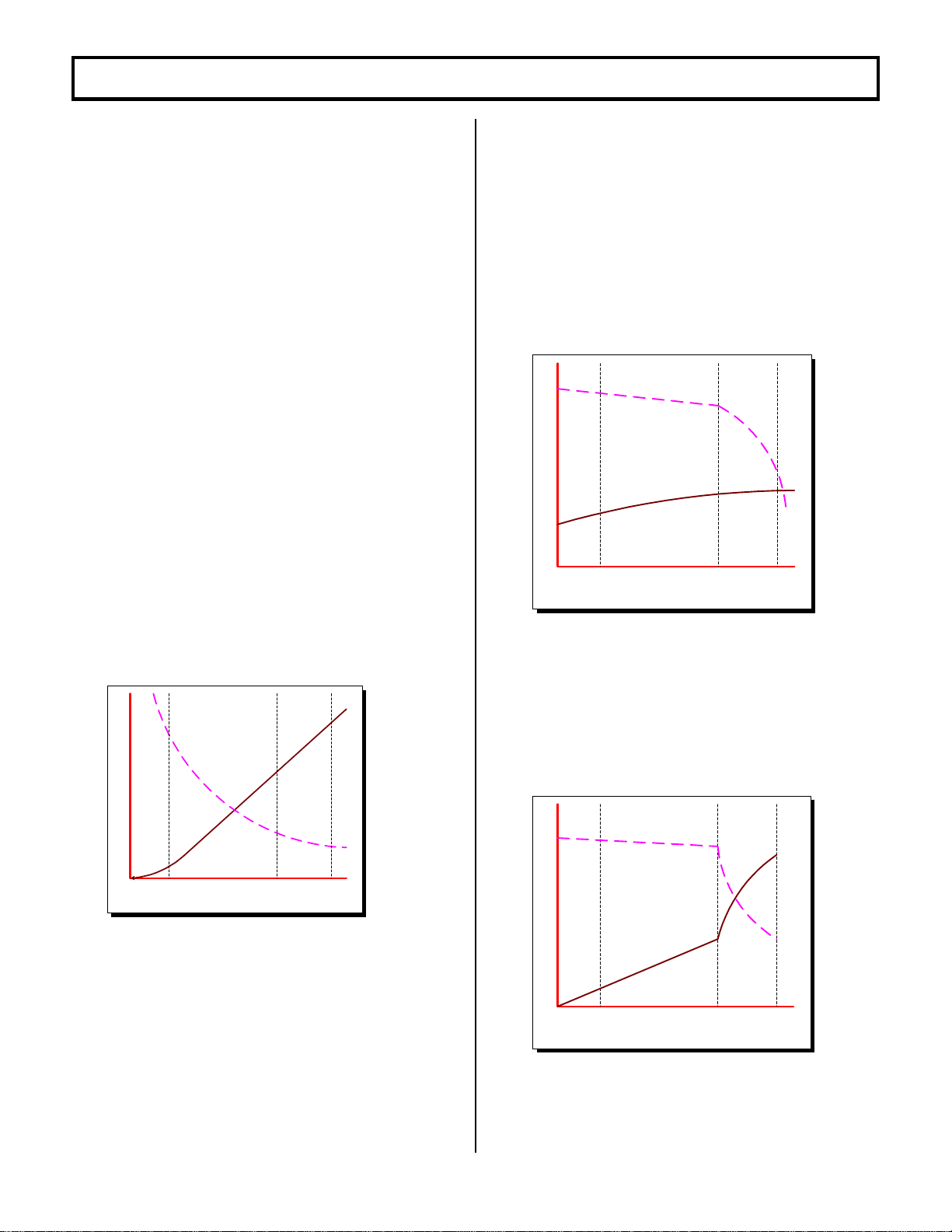

Section 2.1.3.b Regenerative Braking to Zero Speed

Slow down is accomplished when

reversing direction by providing a

small amount of retarding torquefor

deceleration. If the vehicle is

moving, and thedirectional lever is

moved from one direction to the

other, the regen signal is initiated.

Once the regen signal has been

initiated, the field current is

increased. Armature current is

regulated to the regen current limit

as set by Function 9. As the vehicle slows down, thefield

current continues to increase, and transistor Q2 begins to

chop. The field current will increase until it reaches a

preset value set by Function 10, and transistor Q2 on-time

will increase until it reaches 100% on-time. Once both of

the above conditions have been met, and regen current

limit can no longer be maintained, the braking function is

canceled. The fields will then reverse, and the control

reverts back to motoring.

Part of the energy produced by the motor during regen is

returned to the battery, and partis dumped in the motor as

heat.

Section 2.1.3.c PedalPosition Plug Braking

This feature allows control of the plugging distance based

on pedal position when there has been a “directional

switch" change. Pedal position will reduce the plugging

current to the "value set by this function" as the accelerator

is returned to the creep speed position. Maximum plug

current is obtained with the accelerator in the top speed

position. This featureis adjustable by using Function 16 on

the Handset.

Section 2.1.3.d Auto Braking

This featurecan be setup with the Handset using Function

17 to select "Auto Plug/Regen" . Thisfeature is enabled by

initiating a "neutral position" using either the directional

switch or the accelerator switch. Once activated, Auto

Braking operates similar to Pedal Position Plug Braking

and is adjusted by using Function 16 ofthe Handset.

Section 2.1.3.e Brake Pedal Regenerative Braking

This feature sets or varies the amount of REGEN current

with AUTO-REGEN braking feature. The current is variable

through the use of a pot on the brake pedal to provide a

minimum AUTO-REGEN braking level at pedal up, but

increasing as the pedal is depressed. A set level of REGEN

CURRENT LIMIT is available with a set resistor on the brake

pedal. An open inputwith either adjustment modea pot or

resistor will allowcoast until either is selected. Minimum

REGEN CURRENT LIMIT requires a 4200 ohm resistor input

(minimum level 50 amp). Maximum REGEN CURRENT LIMIT

requires a 330 ohm resistor input.

Section 2.1.4 Auxiliary Speed Control

Section 2.1.4.a Field Weakening

This function allows the adjustmentof the field weakening

level in order to set the top speed of the motor. The function

is enabled when the armature current is less than the value

set by Function 24 and the accelerator input voltage isless

than 1 volt. It is important to note that this function is used

to optimizemotor and control performance, and this setting

will be determined by GE and OEM engineers at the time of

vehicle development. This setting must not be changed by

field personnel withoutthe permission of the OEM.

Section 2.1.4.b Speed Limits

This feature provides a means to control speed by limiting

motor volts utilizing three "adjustable speed limits", initiated

by individual limit switches. The NC switches are

connected between input points on the control card and

battery negative. The lower motor volt limit always takes

prioritywhen more than one switch inputis open. This

motor volt limit regulates top speed of the transistor

controller, but actual truck speed will vary at any set point

depending on the loading of the vehicle. Each speed limit

can be adjustable with the Handset using Functions 11, 12,

and 13, for speed limits SL1, SL2, and SL3 respectively. SLl

is active in all card types and must be disabled with the

Handset if speed limits are not used.

ARM

Q1

Q2