© 2015 General Electric Company. All rights reserved.Masoneilan SVI II AP Digital Positioner Quick Start Guide | 3

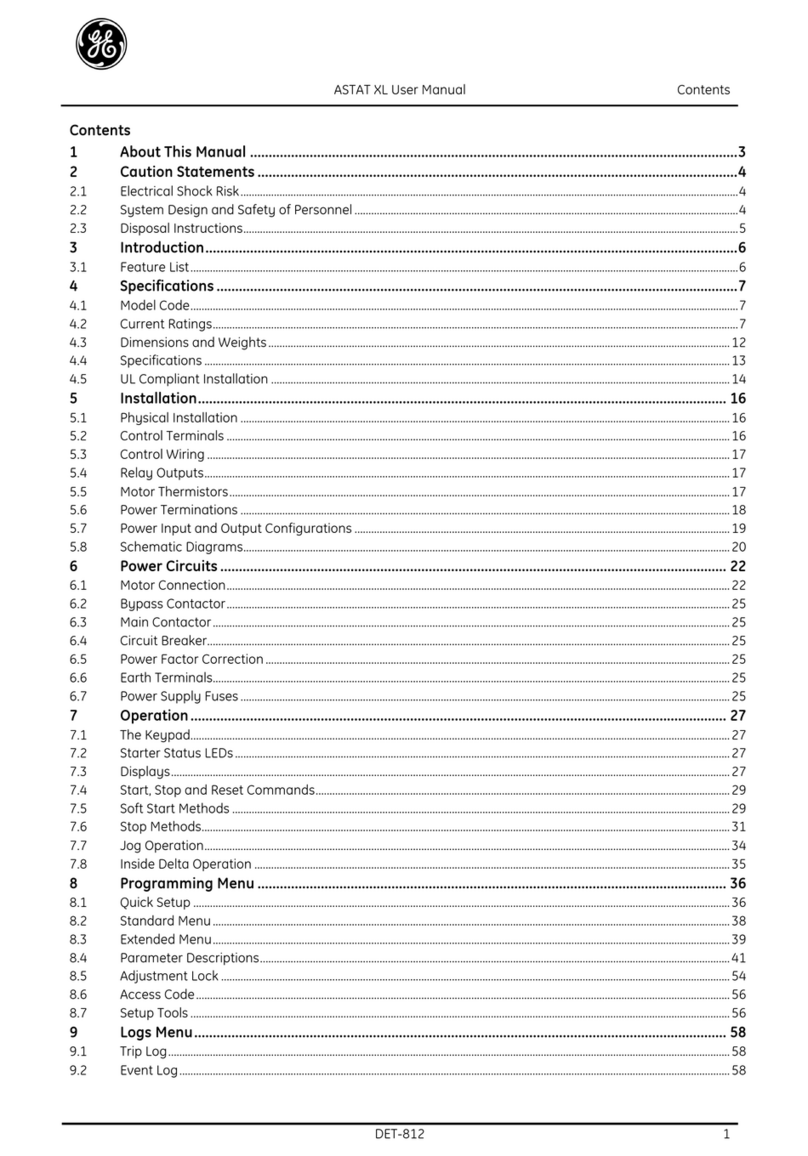

Contents

Safety Information ................................................................................... 7

Safety Symbols ............................................................................................................................7

SVI II AP Product Safety............................................................................................................................ 8

Installation and Set Up ............................................................................ 11

Introduction ...................................................................................................................................11

Using the Quick Start Guide................................................................................................................... 13

Single Acting Positioner............................................................................................................................ 14

Double Acting Positioner ......................................................................................................................... 15

Pushbuttons and Local Display............................................................................................................ 16

Pushbuttons ................................................................................................................................................. 16

ValVue* Software........................................................................................................................................ 20

ValVue Lite .................................................................................................................................................... 20

System Requirements .............................................................................................................................. 20

ValVue Full Trial Version .......................................................................................................................... 20

Mounting the SVI II AP............................................................................................................................... 21

Necessary Precautions ........................................................................................................................... 21

Mounting the SVI II AP on Rotary Valves ......................................................................................... 22

Travel Sensor Alignment ......................................................................................................................... 24

Mounting the SVI II AP on Reciprocating Valves ......................................................................... 25

Checking the Magnet ............................................................................................................................... 29

Installing the SVI II AP for Double- Acting Operation ................................................................. 30

Connecting the Tubing and Air Supply ............................................................................................. 33

Connecting the Air Supply ..................................................................................................................... 34

Wiring the SVI II AP..................................................................................................................................... 34

Connecting to the Control Loop .......................................................................................................... 35

Wiring Guidelines ....................................................................................................................................... 35

SVI II AP Setups ........................................................................................................................................... 36

Grounding Practices ................................................................................................................................. 36

Compliance Voltage in Single Drop Current Mode ..................................................................... 37

Verify Wiring and Connections ............................................................................................................ 37

Check Out, Configuration and Calibration .......................................... 39

Overview .........................................................................................................................................39

Check Out Procedures.............................................................................................................................. 39