BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 6

July 1999

The oscillator section of thecard has two adjustable

features, creep speed and minimum field current. With the

accelerator at maximum ohms or volts, the creep speed

can be adjusted by Function 2 of theHandset or a trimpot.

The field control section allows the adjustmentof the field

weakening level in order to set thetop speed of themotor.

This top speed function (Minimum Field Current) is enabled

when the armature current is less than the value set by

Function 24 and the accelerator inputvoltage is less than 1

volt. Top Speed can beadjusted by Function 7 of the

Handset or a trimpot.

The % ON-time has a range of approximately 0 to 100

percent. The SX controllers operate at a constant

frequency and the% ON-time is controlled by the pulse

width ofthe voltage/current applied to the motor circuits.

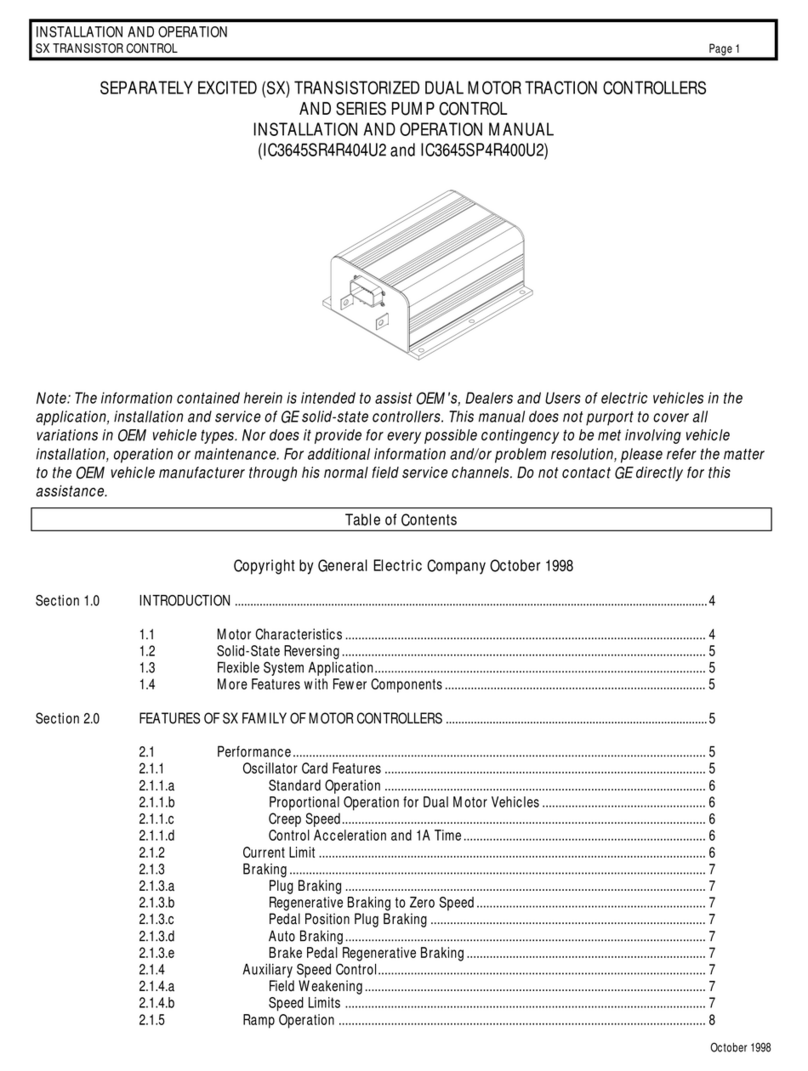

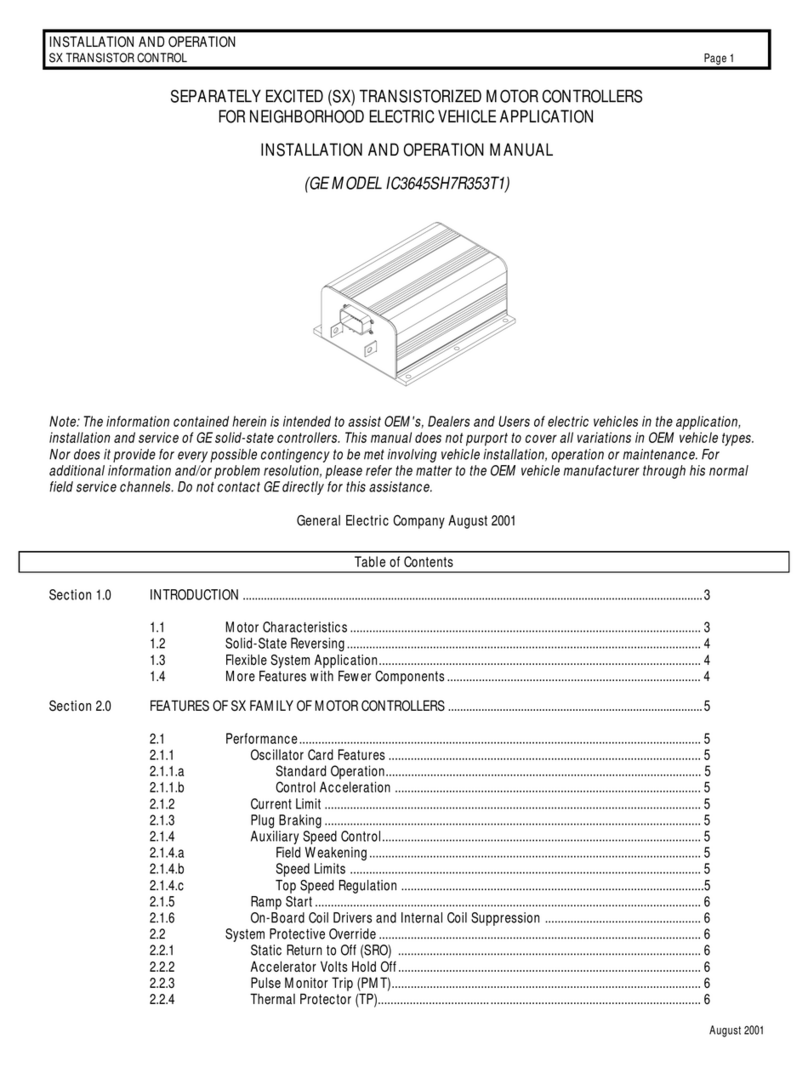

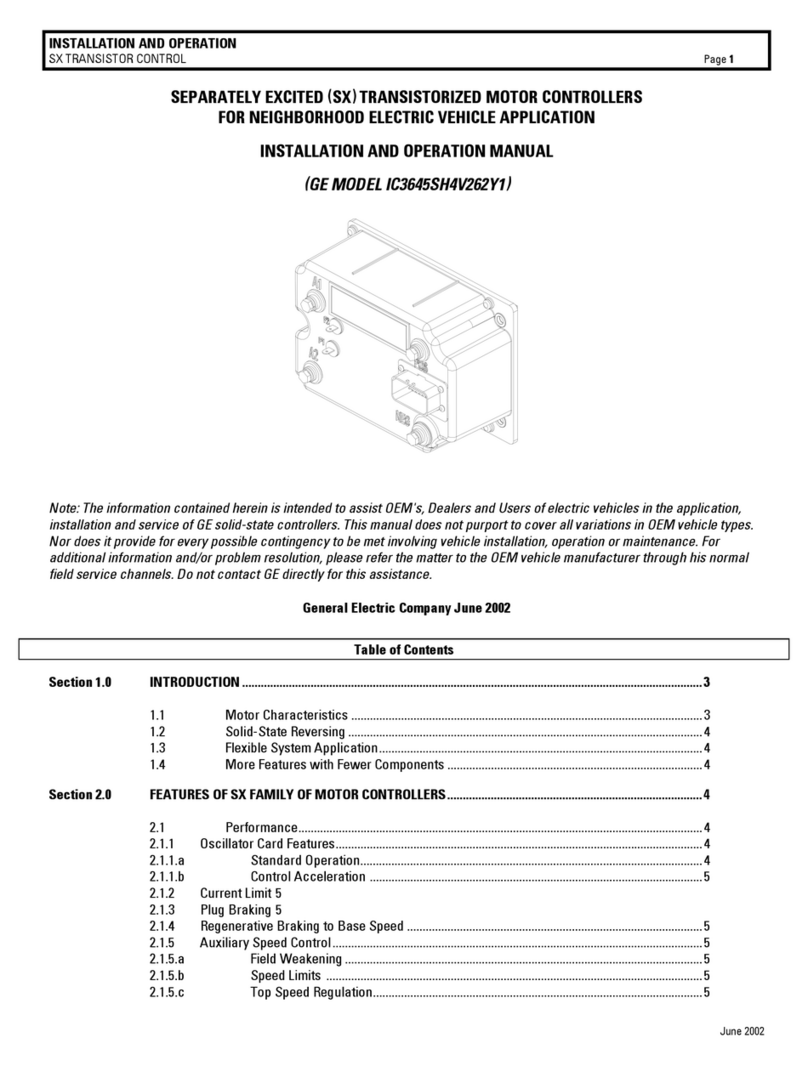

Section 2.1.1.b Proportional Operation for Dual Motor

Vehicles

A key performance advantage of this control is the ability to

achieveactual “proportioning” of motor speed. In a non-

proportioning, or single control, system, when the vehicle

starts to turn, the outside drive wheel turns in a larger

circle than the inside wheel. Depending on the geometry of

the vehicle, at some degree of turn angle, the inside wheel

must slow down to prevent scrubbing of the wheel. This is

accomplished on a single control system by disconnecting

the inside motor and letting the wheel “free wheel” or

“float” at whatever speed is dictated by the outside wheel

that is still under power. The main disadvantage of this

system is that no torque is available on that motor when the

inside wheel is in the “free wheel” mode, and the vehicle

performance in a turn is reduced. When the steer wheel

nears the 90oturn angle, the inside motor is re-connected in

the opposite direction of the outside wheel. At this point,

torque is returned to the inside wheel and the speed is the

same on both motors.

With two controls, the speed of each motor can be

regulated independently. The driver controls the speed of

the outside wheel with the accelerator input signal. The

inside wheel speed is controlled by the turn angle of the

steer wheel. A potentiometer is attached to the steer wheel

in order to communicate the steer angle to the controllers.

During vehicle manufacture, software selection identifies

each control for its application as a right or left control.

The controls are physically identical, and it isonly software

that separates a right from a left control, or differentiates a

control for a dual motor application from one intended for a

single motor vehicle.

With this dual motor system, as the steer reaches some

pre-selected turn angel, approximately 15o, the speed of the

inside wheel decreases proportionally to the speed of the

outside wheel. This proportional decline will continue on a

tangential path, until thesteer angle reaches another

predetermined angle of approximately 70o. At this point, the

inside wheel will stop. As the steer angle is increased

toward the 90opoint, the inside wheel will reverse direction

and start to accelerate proportionally in speed. As the

steer angle reaches the 90opoint, the inside wheel speed

will be the same as that of the outside wheel. During this

entire turn, except for several degrees when the motor was

stopped to reverse direction, torque was always present on

the inside wheel, providing a smoother ride throughout the

turning radius ofthe vehicle.

Details for the adjustment of the steer angle potentiometer

can be found in Section 7 ofthis manual.

0

O

10

O

10

O

20

O

20

O

30

O

30

O

40

O

40

O

50

O

50

O

60

O

60

O

70

O

70

O

80

O

80

O

90

O

100%

50%

50%

100%

90

O

100%

50%

50%

100%

RIGHT

MOTOR LEFT

MOTOR

STEERING ANGLE

LEFT

TURN RIGHT

TURN

LEFT

MOTOR RIGHT

MOTOR

RIGHT

CONTROL

LEFT

CONTROL

0

O

90

O

90

O

REV - SPEED - FWD

REV - SPEED - FWD

Section 2.1.1.c Creep Speed

With the accelerator at minimum speed, the creep speed

can be adjusted by Function 2 of the Handset. At creep

speed, the ON time can decreased to approximately 5%,

with the OFF time at approximately 95%. At full transistor

operation, this condition will be reversed (shortOFF time,

long ON time). This variation of ON and OFF time of the

oscillator varies the voltage applied to the motor, thereby

varying the speed of the motor for a given load.

Section 2.1.1.d Control Acceleration

This feature allows for adjustment of the rate of time it

takes for the control to accelerate to 100% applied battery

voltage to the motor on hard acceleration. Armature C/A is

adjusted by Function 3 from 0.1 to 6 seconds.

Section 2.1.2 Current Limit

This circuit monitors motor current by utilizing sensors in

series with the armature and field windings. The

information detected by the sensor is fed backto the card

so that current may be limited to a preset value. If heavy

load currents are detected, this circuit overrides the

oscillator and limits the average currentto a value set by

Function 4 and Function 8 of the Handset. The C/L setting is

based on the maximum thermal rating of the control.

Because of the flyback current through Q6, the motor

current isusually greater than battery current, except at

100% ON time.