BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 4

Section 1. 2 Solid-State Reversing

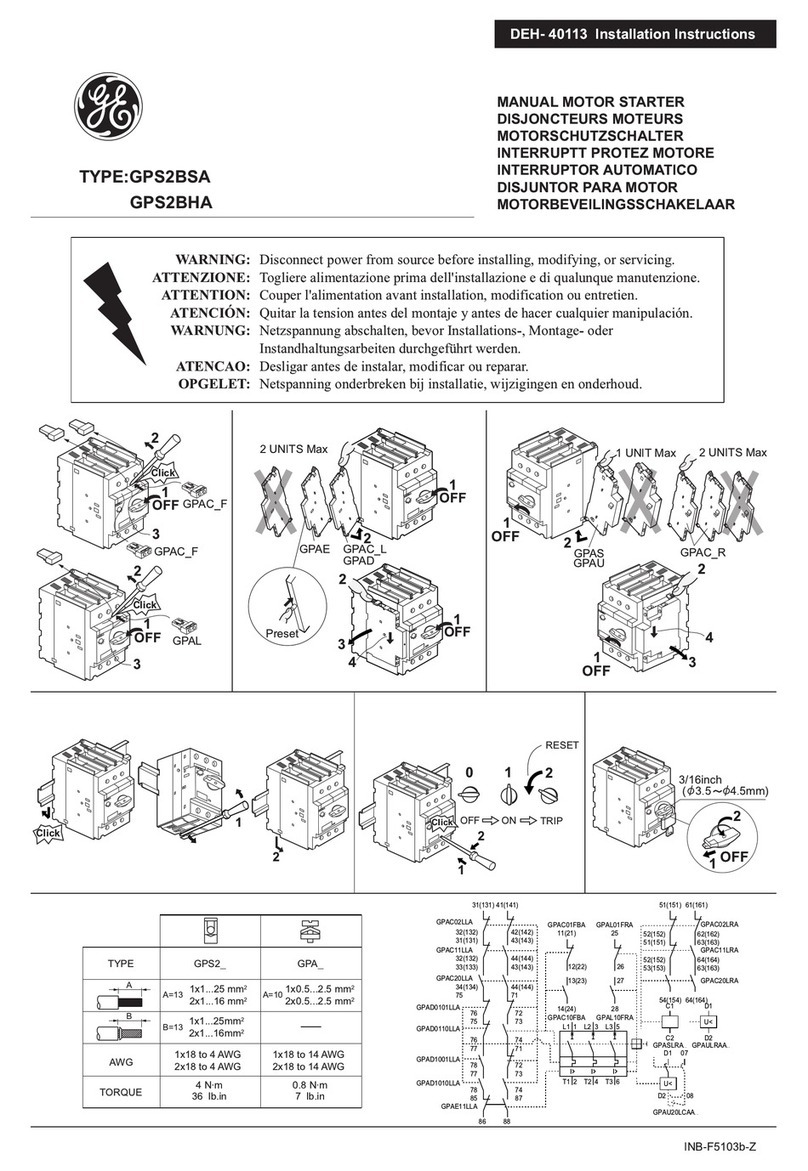

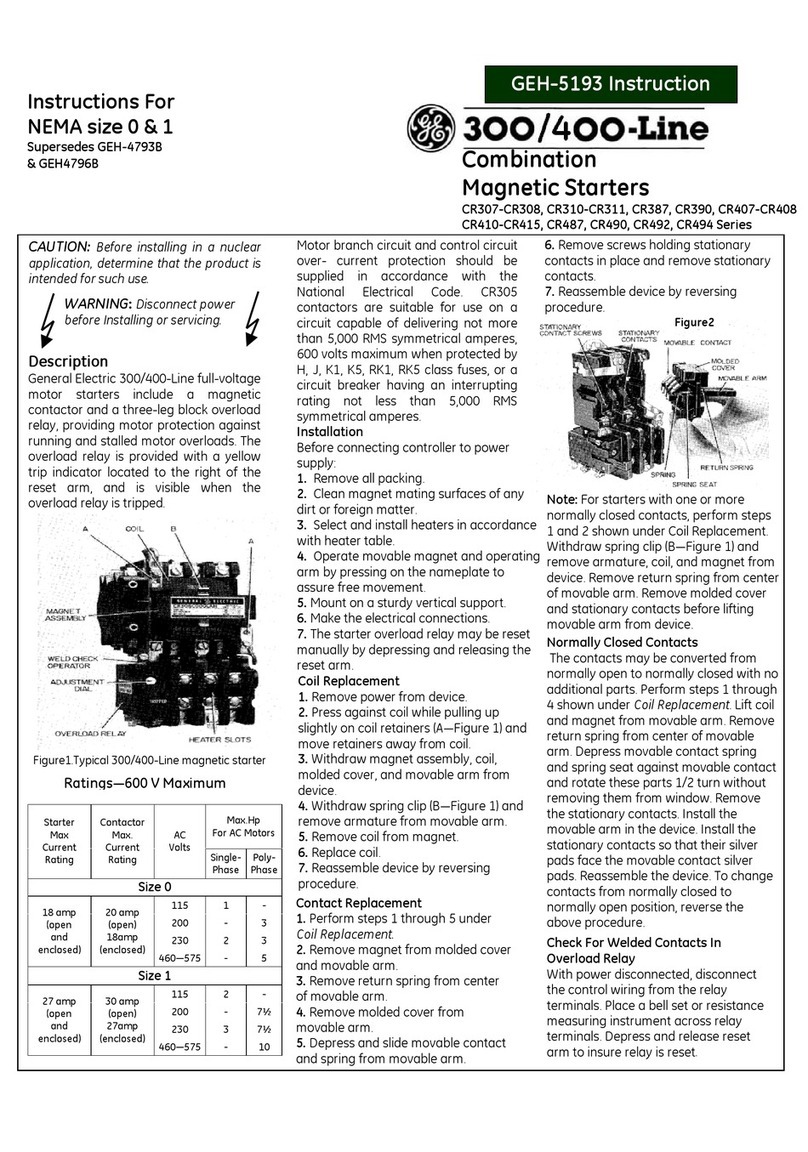

The direction of armature rotation on a shunt motor is

determined by the direction in which current flows through

the field windings. Because of the shunt motor field,

typically only requires about 10% of the armature current at

full torque, it is normally cost effective to replace the

double-pole, double-throw reversing contactor with a low

power transistor H-Bridge circuit (Figure 4).

By energizing the transistors in pairs, current can be made

o flow in either direction in the field. The field andt

armature control circuits typically operate at 12KHZ to

15KHZ, a frequency range normally above human

hearing. This high frequency, coupled with the elimination

of directional contactors, provides for very quiet vehicle

operation.

he line contactor is normally the only contactor requiredT

for the shunt motor traction circuit. This contactor is used

or both pref -charge of the line capacitors and for

emergency shut down of the motor circuit, in case of

problems that would cause a full motor torque condition.

The line can be energized and de-energized by the various

ogic combinations of the vehicle, i.e. activate on key, seatl

or start switch closure, and de-energize on time out of idle

ehicle. Again, these options add to the quiet operation ofv

he vehicle.t

ection 1. 3 Flexible System ApplicationS

Because the shunt motor controller has the ability to

control both the armature and field circuits independently,

the system can normally be adjusted for maximum system

efficiencies at certain operating parameters. Generally

speaking, with the ability to independently control the field

nd armature, the motor performance curve can bea

maximized through proper control application.

Section 1. 4 More Features with Fewer Components

Field weakening with a series wound motor is

accomplished by placing a resistor in parallel with the field

inding of the motor. Bypassing some of the currentw

lowing in the fielf d into the resistor causes the field current

to be less, or weakened. With the field weakened, the

motor speed will increase, giving the effect of “overdrive”.

To change the “overdrive speed”, it is necessary to change

the resistor value. In a separately excited motor,

independent control of the field current provides for infinite

adjustments of “overdrive” levels, between the motor base

speed and maximum weak field. The desirability of this

feature is enhanced by the elimination of the contactor and

resistor required for field weakening with a series motor.

With a separately excited motor, overhauling speed limit,

or downhill speed, will also be more constant. By its

nature, the shunt motor will try to maintain a constant

speed downhill. This characteristic can be enhanced by

increasing the field strength with the control.

Overhauling load control works in just the opposite way

of field weakening, as armature rotation slows with the

increase of current in the field. An extension of this

feature is a zero-speed detect feature which prevents

the vehicle from free-wheeling down an incline, should

the operator neglect to set the brake.

Regenerative braking (braking energy returned to the

battery) may be accomplished completely with solid-

state technology. The main advantage of regenerative

braking is increased motor life. Motor current is

reduced by 50% or better during braking while

maintaining the same braking torque as electrical

braking with a diode clamp around the armature. The

lower current translates into longer brush life and

reduced motor heating. Solid state regenerative braking

also eliminates a power diode, current sensor and

contactor from the circuit.

For GE, the future is now, as we make available a new

generation of electric traction motor systems for electric

vehicles having separately excited DC shunt motors and

controls. Features that were once thought to be only

available on future AC or brushless DC technology

vehicles systems are now achievable and affordable.

Section 2. FEATURES OF SX FAMILY OF TRANSISTOR

MOTOR CONTROLLERS

Section 2.1 Performance

Section 2.1.1 Oscillator Card Features

Section 2.1.1.a Standard Operation

The oscillator section of the card has two adjustable

features, creep speed and minimum field current. The

creep speed can be adjusted by Function 2 of the handset.

The field control section allows the adjustment of the field

weakening level in order to set the top speed of the motor.

This top speed function (Minimum Field Current) is enabled

when the armature current is less than the value set by

Function 24. Top Speed can be adjusted by Function 7 of

the handset .

The % ON-time has a range of approximately 0 to 100

percent. The SX controllers operate at a constant

frequency and the % ON-time is controlled by the pulse

width of the voltage/current applied to the motor circuits.

FUSE

LINE

CAP ARM F2F1

Q3

Q4

Q5

Q6

Q1

POS

NEG

Figure 4

A1 +

A2 -

Q2

Updated Sept 2019