– 8 –

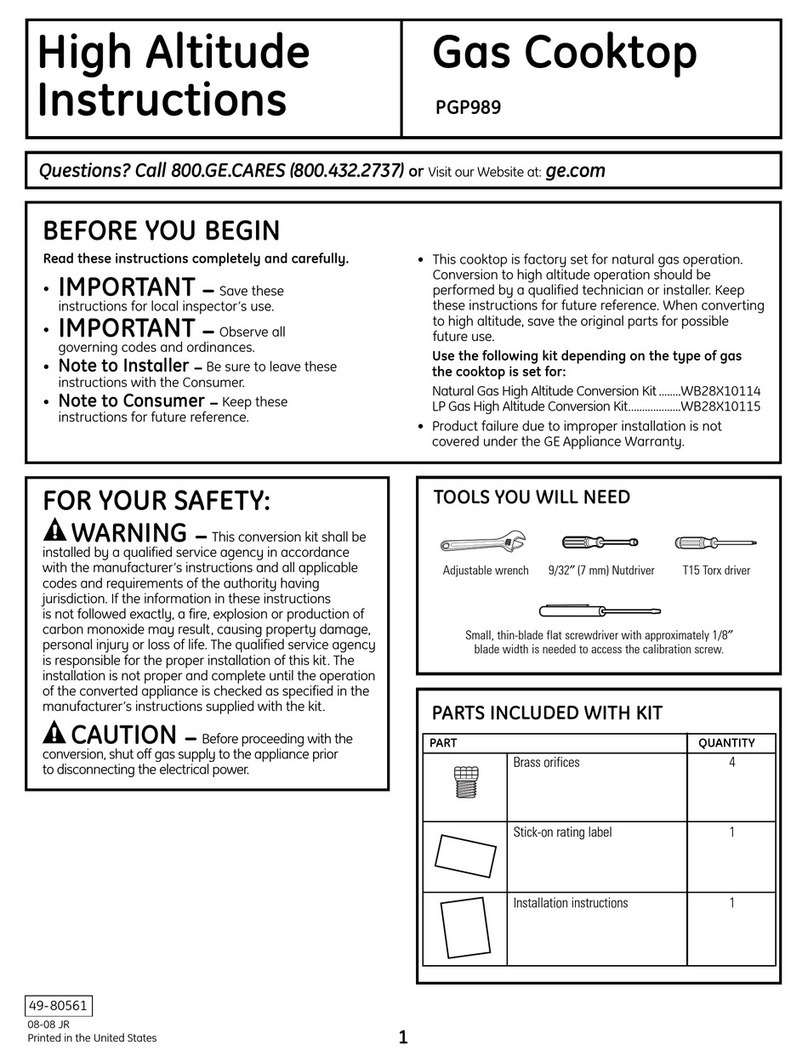

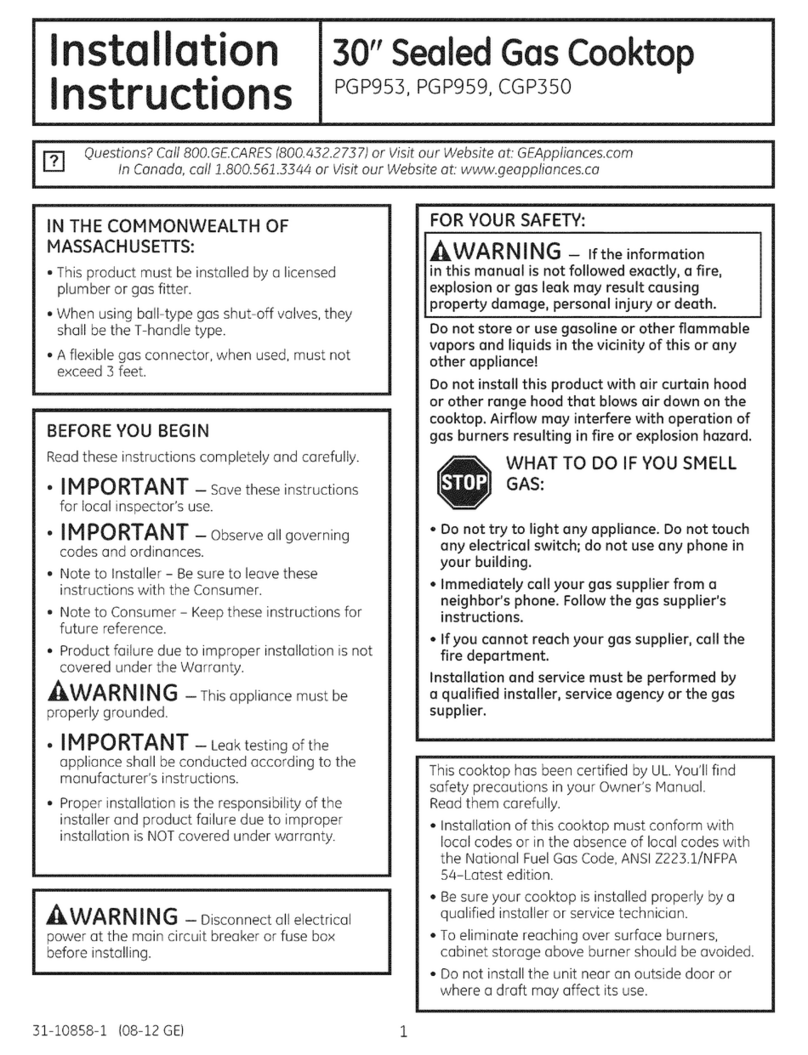

Installation Requirements

Before you begin, read these instructions

completely and carefully.

Note: Save these instructions for local inspector’s

use.

• Observe all governing codes and ordinances.

• Installation of this unit requires 2 people. Do not

attempt to install without assistance.

• This appliance must be properly grounded.

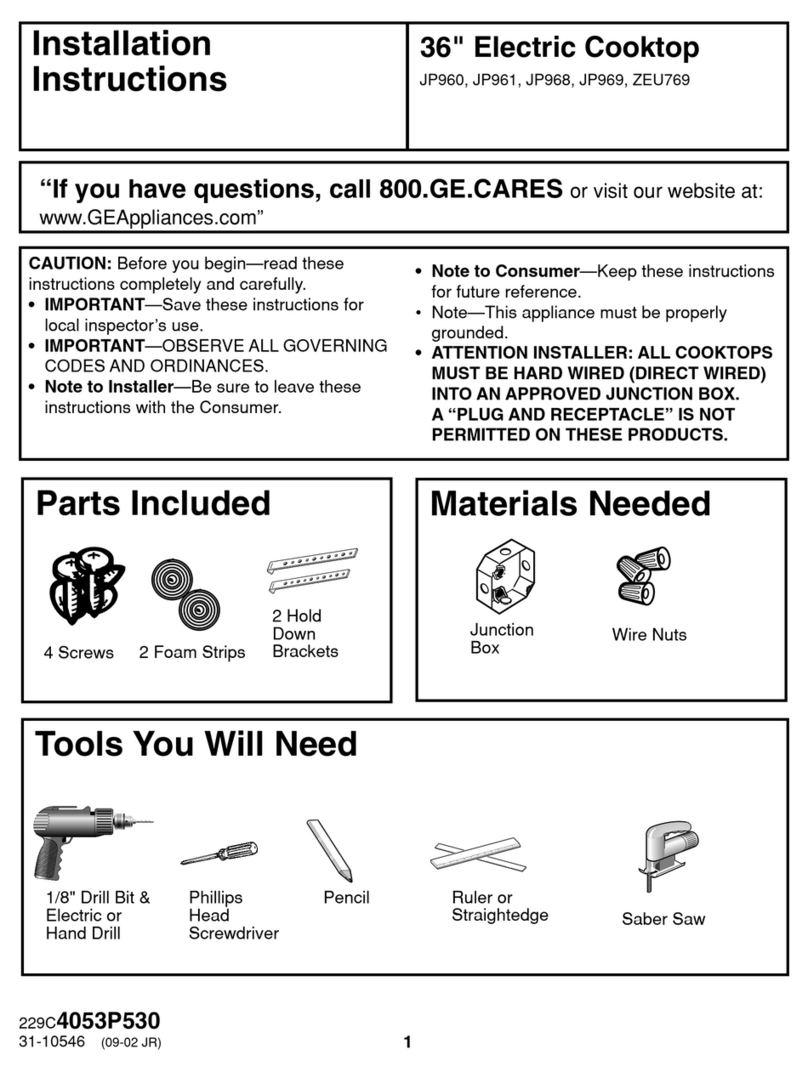

Tools and MaterialsYouWill Need:

•Saw

• Flat blade screwdriver

• Electrician’s pliers

• Duct tape

• Measuring tape or scale

• Carpenter’s square

• Wrench or socket set

• Drill and drill bit

• Sheet metal screws

• Junction box*

• 1/2 in.flexible conduit*

• Electrical cable per local code*

• Wire nuts*

• Duct work

*Note: Electrical installation kit JXCK89 may be

ordered separately and includes all the parts

necessary to connect the cooktop to typical rough-

in wiring.

Electrical Requirements

WARNING: For personal safety, remove house fuse

or circuit breaker before beginning installation.

This appliance must be supplied with the proper

voltage and frequency, as listed in these Installa-

tion Requirements, and connected to an indi-

vidual, properly grounded branch circuit, protected

by a 40-amp circuit breaker or time-delay fuse.

All wire connections must be made in accordance

with local codes and properly insulated. Check

with your local utility for governing electrical codes

and ordinances. In the absence of local electrical

codes, the National Electrical Code, ANSI/NFPA

No. 70–Latest Edition, governing electric range

installations, must be followed.

A copy of the National Electrical Code can be

obtained by writing to:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02260

Effective January 1, 1996, the National Electrical

Code requires that new, but not existing, construc-

tion utilizes a four-conductor connection to an

electric range.When installing an electric range in

new construction, follow the instructions in New

Construction and Four-Conductor Branch

Circuit Connection.

You must use a three-wire, single-phase AC

208Y/120-Volt or 240/120-Volt, 60-Hertz electrical

system with separate ground.If you connect to

aluminum wiring, properly installed connectors

approved for use with aluminum wiring must be

used.

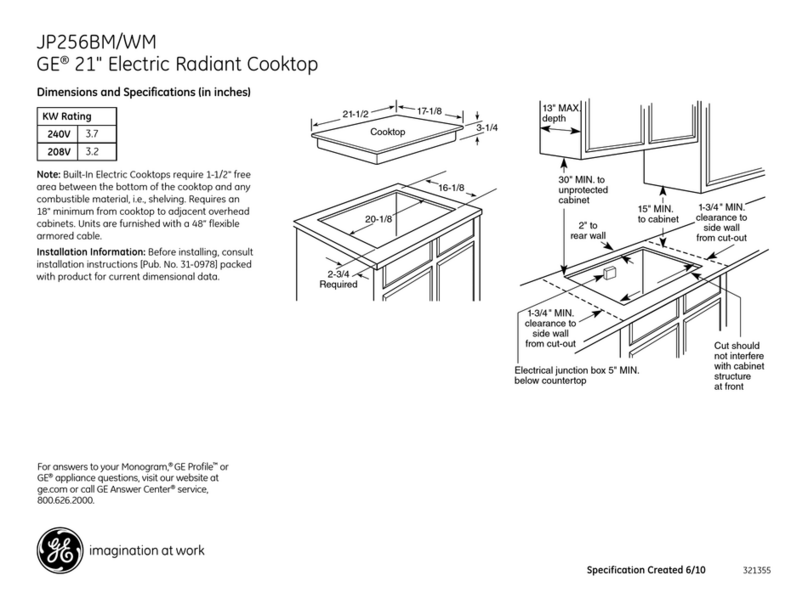

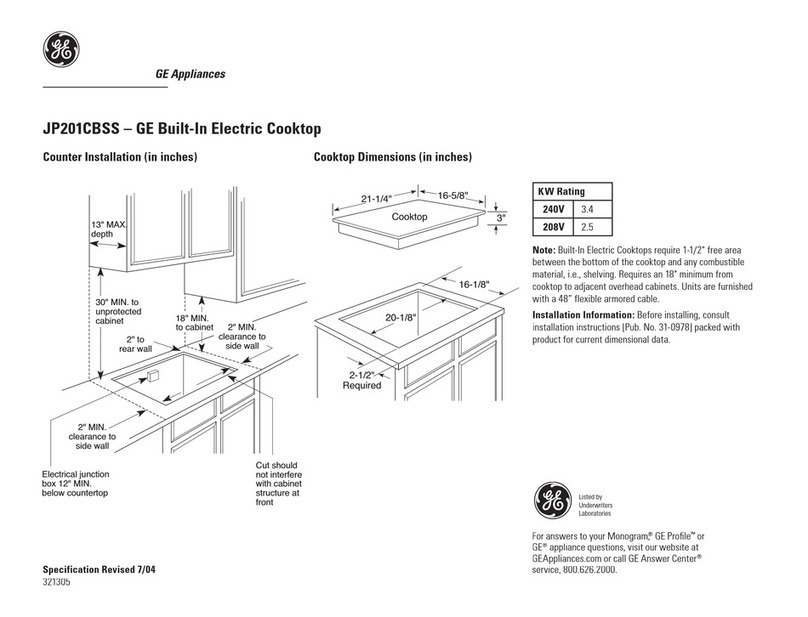

21 "

78

20 "

12

19"

6"

Dia.

Nomenclature

(on other side)

Mini-manual

located behind

cover

29 "

78

6"

28 "

78

30

"

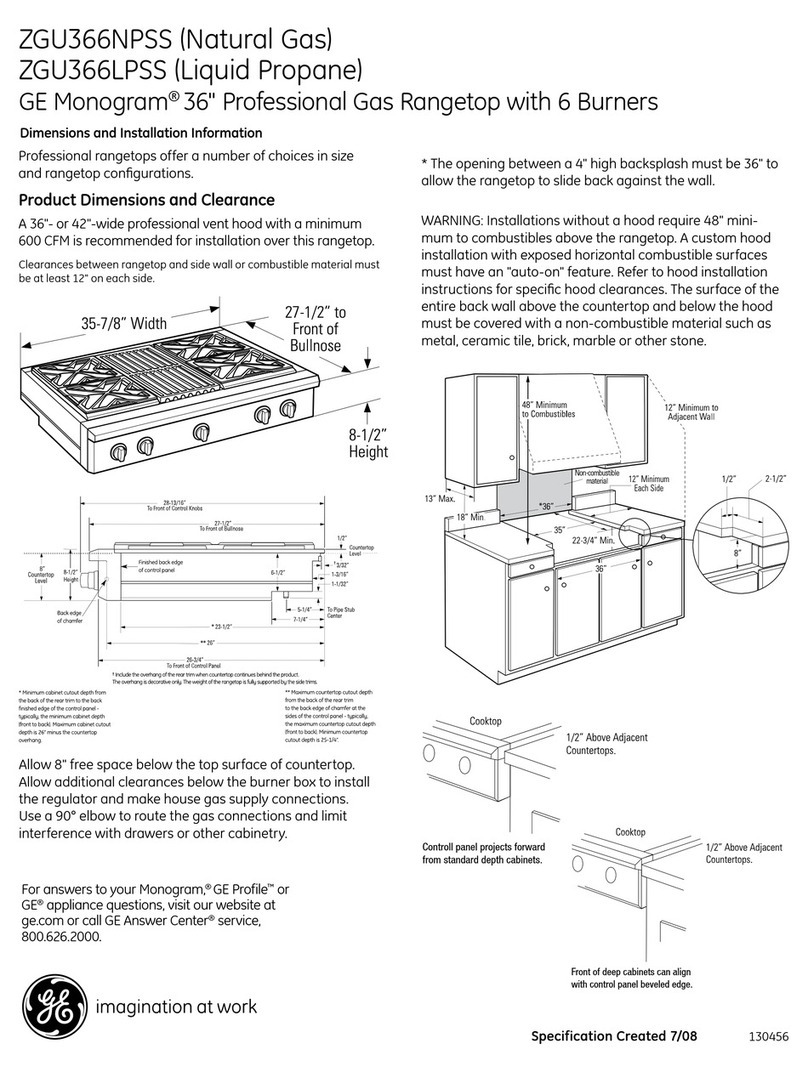

Cooktop (Dimensions for reference only) Unit must be vented to the outside!

GEA00193