GE 3300 User manual

Other GE Measuring Instrument manuals

GE

GE DigitalFlow GC868 User manual

GE

GE Hydran M2-X User manual

GE

GE Intellix BMT 330 User manual

GE

GE JXSOUSV1 User manual

GE

GE DigitalFlow DF868 Owner's manual

GE

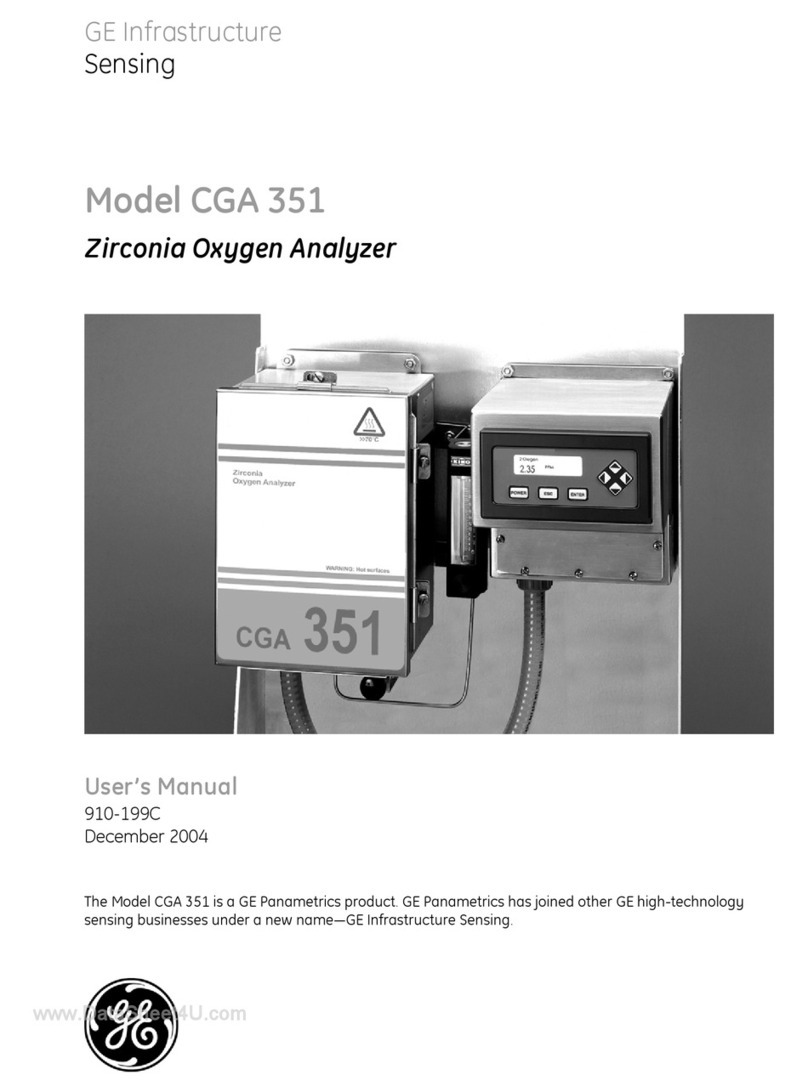

GE CGA 351 User manual

GE

GE DigitalFlow GS868 User manual

GE

GE Moisture Image 1 Series User guide

GE

GE PACE 1000 Instruction Manual

GE

GE AquaTrans AT600 User manual

GE

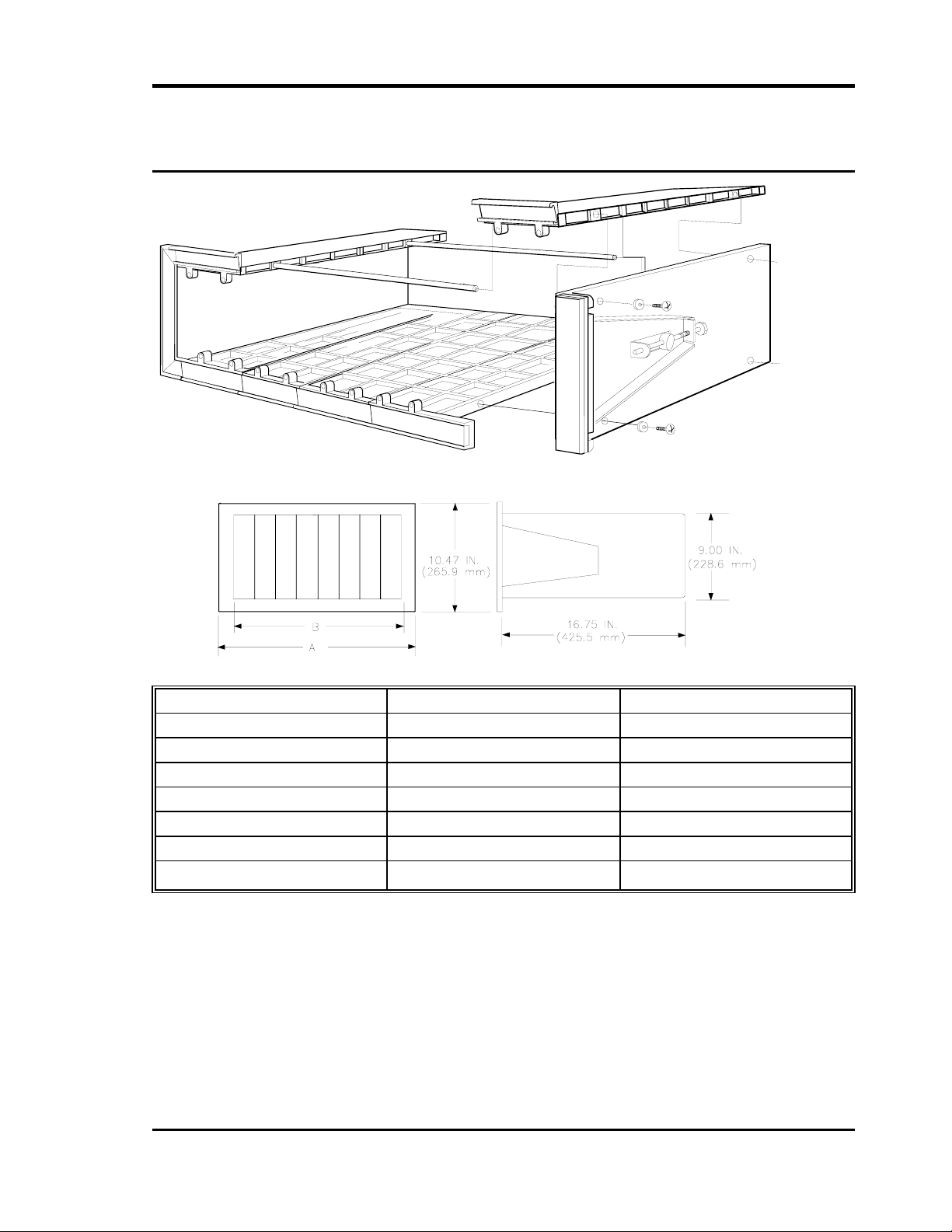

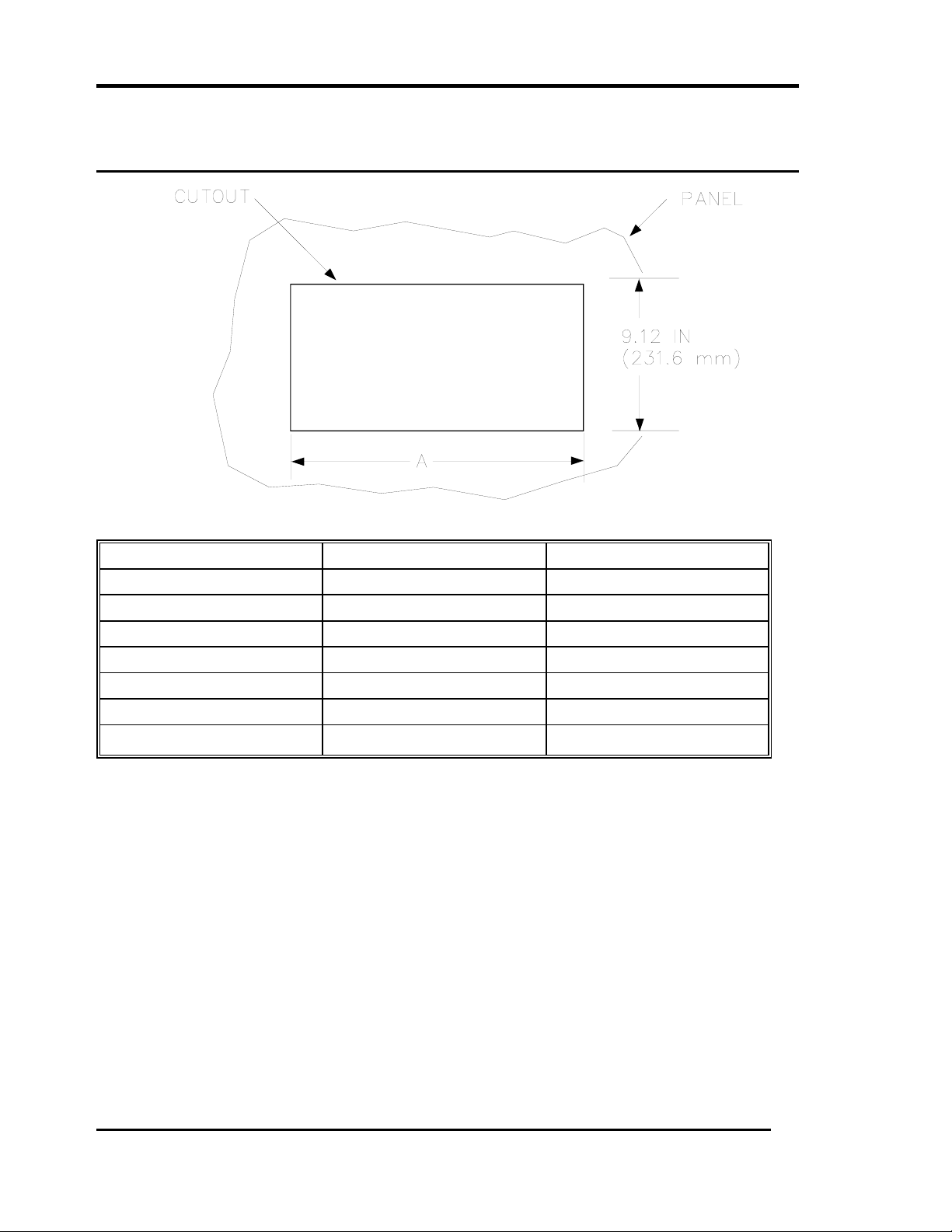

GE 68K System User manual

GE

GE Moisture Image 1 Series Owner's manual

GE

GE 3300 User manual

GE

GE EPM 5300 User manual

GE

GE SCOUT100-Ex User manual

GE

GE Centricity MP3510 User manual

GE

GE DigitalFlow DF868 User guide

GE

GE AutoSigma 3000 DL Use and care manual

GE

GE RHM 20 User manual

GE

GE Druck DPI 705 User manual