v

Contents

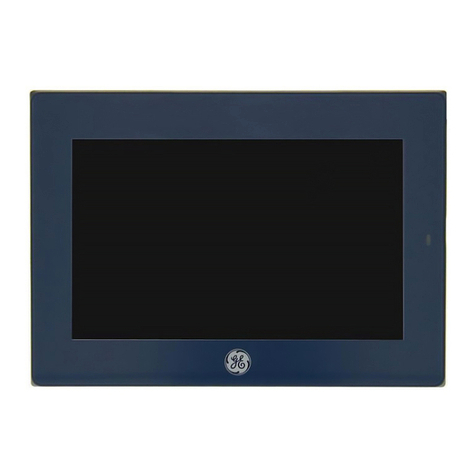

1. 1900/27 Vibration Monitor Description ..................................................... 1

1.1 Features................................................................................................................................................. 1

1.2 Monitor onnections, Indicators, & ontrols.......................................................................... 4

2. Installation...................................................................................................... 6

2.1 Receiving Inspection........................................................................................................................ 6

2.2 Jumper Settings................................................................................................................................. 6

2.2.1 Setting Relays for Latching or Non-Latching Behavior............................................... 7

2.2.2 Setting Relays for Normally Energized or Normally De-energized Behavior .... 7

2.2.3 Setting 4 to 20 mA Interface Behavior During 1900/27 Monitor Bypass............ 8

2.2.4 Internal Jumper Location ......................................................................................................... 9

2.3 Monitor Enclosure.............................................................................................................................. 9

2.4 onfiguration Switch Settings...................................................................................................10

2.4.1 Relay Time Delay ........................................................................................................................10

2.4.2 Alert Relay Alarm onditions.................................................................................................10

2.4.3 onfiguring the Display for English or Metric Units ....................................................11

2.4.4 Initiating Self Test.......................................................................................................................11

2.5 onnecting Remote Reset............................................................................................................12

2.6 4 to 20 mA Interface onnections...........................................................................................12

2.6.1 onnecting able to the 1900/27 Monitor 4 to 20 mA Interface .........................12

2.7 Relay onnections ..........................................................................................................................15

2.7.1 Alert Relay onfiguration........................................................................................................16

2.7.2 Relay Internal Jumper Settings.............................................................................................17

2.7.3 Relay Electrical onnections..................................................................................................17

2.8 Power onnections ........................................................................................................................19

2.8.1 Types of Power onnections.................................................................................................19

2.8.2 Power Electrical onnections ...............................................................................................19

2.9 Field Wiring Diagram.....................................................................................................................21

3. Monitor Operation....................................................................................... 22

3.1 Monitor Display ................................................................................................................................22

3.1.1 English or Metric Display Units.............................................................................................22

3.1.2 The Display Mode Switch........................................................................................................23

3.1.3 Display Error odes ...................................................................................................................24

3.2 LED Indicators...................................................................................................................................25

3.3 Relay Mode Switch ..........................................................................................................................26