GE Power Management 269Plus Motor Management Relay

i

TABLE OF CONTENTS

1. INTRODUCTION 1.1 MOTOR PROTECTION REQUIREMENTS............................................... 1-1

1.2 FEATURES................................................................................................ 1-1

1.3 TYPICAL APPLICATIONS......................................................................... 1-4

1.4 ORDER CODE / INFORMATION .............................................................. 1-5

1.5 TECHNICAL SPECIFICATIONS................................................................ 1-6

1.6 MPM OPTION SPECIFICATIONS............................................................. 1-9

2. INSTALLATION 2.1 PHYSICAL DIMENSIONS ......................................................................... 2-1

2.2 MOUNTING ............................................................................................... 2-6

2.3 EXTERNAL CONNECTIONS .................................................................... 2-7

2.4 CONTROL POWER................................................................................. 2-12

2.5 PHASE CT INPUTS................................................................................. 2-14

2.6 GROUND CT INPUT ............................................................................... 2-15

2.7 TRIP RELAY CONTACTS.......................................................................2-17

2.8 ALARM RELAY CONTACTS................................................................... 2-18

2.9 AUXILIARY RELAY #1 CONTACTS........................................................ 2-18

2.10 AUXILIARY RELAY #2 CONTACTS........................................................ 2-19

2.11 RTD SENSOR CONNECTIONS.............................................................. 2-19

2.12 EMERGENCY RESTART TERMINALS .................................................. 2-20

2.13 EXTERNAL RESET TERMINALS ........................................................... 2-21

2.14 ANALOG OUTPUT TERMINALS (NON-ISOLATED).............................. 2-21

2.15 DIFFERENTIAL RELAY TERMINALS..................................................... 2-21

2.16 SPEED SWITCH TERMINALS................................................................ 2-22

2.17 PROGRAMMING ACCESS TERMINALS................................................ 2-22

2.18 RS485 SERIAL COMMUNICATIONS TERMINALS................................2-22

2.19 DISPLAY ADJUSTMENT......................................................................... 2-24

2.20 FRONT PANEL FACEPLATE.................................................................. 2-24

2.21 SPARE INPUT TERMINALS ................................................................... 2-24

2.22 DRAWOUT RELAY OPTION................................................................... 2-25

2.23 METER OPTION INSTALLATION........................................................... 2-29

a MPM EXTERNAL CONNECTIONS...................................................... 2-29

b MPM WIRING....................................................................................... 2-29

c CONTROL POWER (5/6/7/8)............................................................... 2-29

d VT INPUTS (1-4) .................................................................................. 2-30

e CT INPUTS (9-20)................................................................................ 2-30

f SERIAL COMMUNICATIONS PORT (COM1 - 46,47,48) .................... 2-31

g MPM ANALOG OUTPUT...................................................................... 2-31

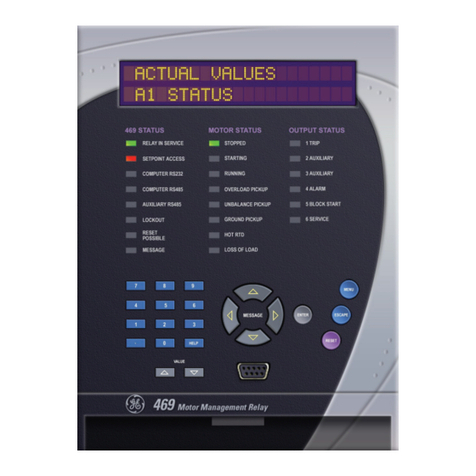

3. SETUP AND USE 3.1 FRONT PANEL.......................................................................................... 3-1

3.2 CONTROLS AND INDICATORS............................................................... 3-2

3.3 RELAY DISPLAY MODES......................................................................... 3-6

3.4 ACTUAL VALUES MODE.......................................................................... 3-7

a STARTS/HOUR TIMER........................................................................ 3-15

b TIME BETWEEN STARTS TIMER....................................................... 3-16

c CAUSE OF LAST TRIP........................................................................ 3-16

d CAUSE OF LAST EVENT ....................................................................3-16

3.5 SETPOINTS MODE................................................................................. 3-17

3.6 HELP MODE............................................................................................ 3-43

3.7 TRIP/ALARM MODE................................................................................ 3-43

3.8 PHASE CT & MOTOR FULL LOAD CURRENT SETPOINTS................. 3-47

3.9 ACCELERATION TIME SETPOINT ........................................................ 3-47

3.10 INHIBITS.................................................................................................. 3-48

3.11 UNBALANCE SETPOINTS...................................................................... 3-49

3.12 GROUND FAULT (EARTH LEAKAGE) SETPOINTS.............................. 3-50