3

Programming/Operating the Module

Refer to specific panel Installation Instructions for module

programming and operation.

Module Wiring Terminal Connections

Figure 6. RS-232 Module Wiring Terminal Connections

Troubleshooting

Specifications

Notices

FCC Part 15 Information to the User

Changes or modifications not expressly approved by GE Security can void the

user’s authority to operate the equipment.

FCC Part 15 Class A

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy, and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case users will be required to

correct the interference at their own expense.

FCC Part 15 Class B

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy, and, if not

installed and used in accordance with the instructions, may cause harmful interfer-

ence to radio communications. However, there is no guarantee that interference will

not occur in a particular installation.

If this equipment does not cause harmful interference to radio or television recep-

tion (which can be determined by turning the equipment off and on), the user is

encouraged to correct the interference by one or more of the followig measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the affected equipment and the panel receiver to separate outlets on

different branch circuits.

Consult a dealer or experienced radio/TV technician for help.

Table 2. RS-232 Module Wiring Terminal Connections

Terminal Name Use

1 +12V DC SuperBus DC power supply input. Maximum

draw from panel at 12V DC is 35 mA.

3 Bus A SuperBus communication connection.

4 Bus B SuperBus communication connection.

5 GND SuperBus common ground connection.

6 Zone 1 Zone 1 input connection.

7 ZCom Zone input common connection.

1 2 3 4 5 6

+ 1 2 V D C

B U S A

B U S B

G N D

Z C O MZ O N E 1

Module Circuit Board DB-9

Serial Cable

Automation

Device

To Pa ne l

Te r m i n al s

Wiring Harness

<OR>

UL Listed

(N/C) Contacts

in Series

UL Listed

(N/O) Contacts

in Parallel

2.0k Ohm EOL

Resistor (49-467)

Install at Last Contact

or

Table 3. Maximum Wire Lengths

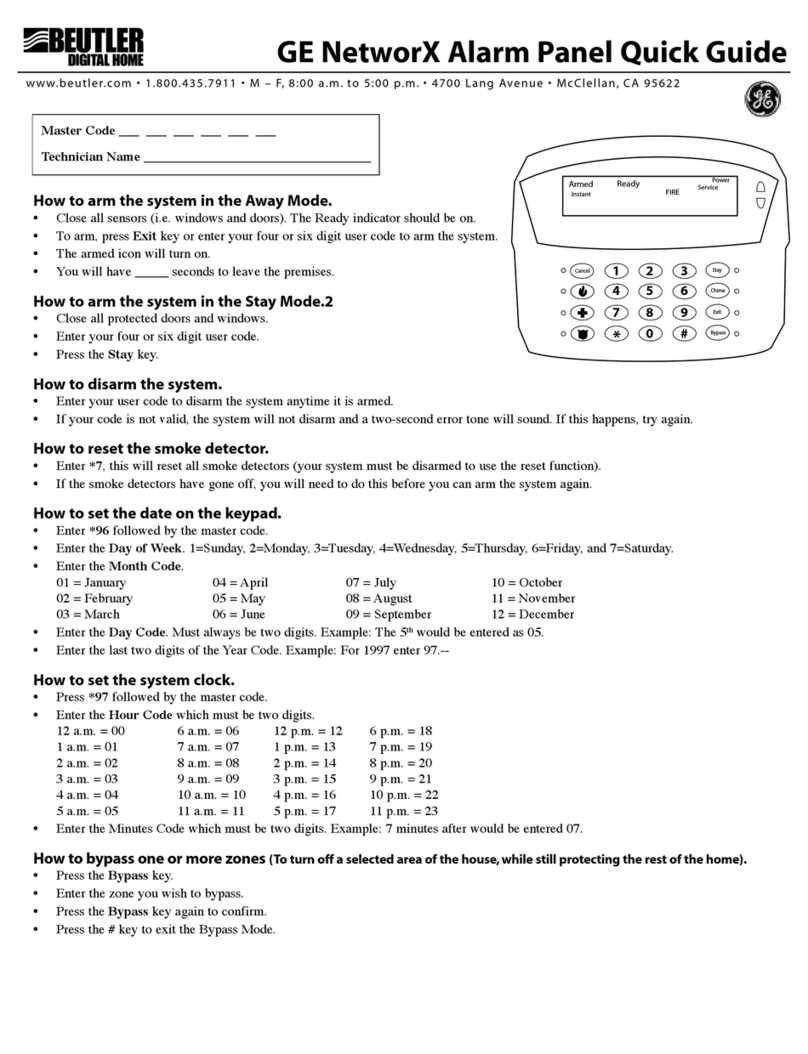

Problem Solution

Power LED remains off • Check for proper wiring connections.

• Ensure the panel’s AC power supply and

backup battery are connected.

• If the LED remains off, replace the module.

Bus LED remains off • Check for proper wiring connections.

• Check for proper module programming and

initialization.

Bus LED remains on • Set panel power from OFF to ON.

Bus LED flashes –

devices do not function

• Ensure device power is set to ON.

• Check for proper wiring connections.

• Check for proper module programming.

Compatibility Advent, Concord (v2.5-later), Concord 4, and

Concord Express (v4) panels

Power Requirements 12V DC nominal; 35 mA maximum (from panel or

auxiliary power supply)

Automation Port RS-232, DCE

Panel Data Bus GE Security auto addressing digital data bus

Dimensions 2.60” x 2.60” x 0.90” (L x W x D)

Zone Input One supervised, fire-rated zone

Storage Temperature -30° to 140°F (-34° to 60°C)

Operating Temperature 32° to 140°F (0° to 60°C)

Maximum Humidity 85%, non-condensing

Dimensions 6.0” x 8.5” x 1.5” (L x W x D)

Case Material High-impact, ABS plastic

Case Color Belgian gray

Installation Wall mount

GE Security

1275 Red Fox Road

Arden Hills, MN 55112

Technical Support

T: 800.777.2624

F: 651.779.4890

www.gesecurity.com