A directional coupler is used to monitor the output power.

The coupler output voltage is compared with the output of U1

which in turn controls the collector voltage of driver stages Q1

and Q2. The coupler voltage can be used as a power output

level indication when properly calibrated. The feedthrough ca-

pacitor CS located on W3A1 is a convenient place to measure

the control voltage.

MAINTENANCE

DISASSEMBLY

For a more complete mechanical parts breakdown, refer to

the station MAINTENANCE MANUAL.To service the trans-

mitter exciter from the front of the station:

1. Turn the two latching knobs on the front of the radio

housing counterclockwise to unlatch the radio hous-

ing front door.

2. Swing the door down.

3. Remove cover from the radio housing.

To remove Exciter Board:

1. Unplug the cables P101 and J902 from the exciter.

2. Remove the four screws and two stand-offs holding

the exciter board to the mounting frame and gently lift

the exciter board out of the radio.

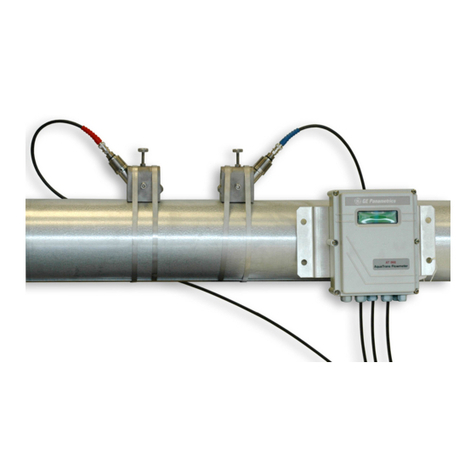

Power Amplifier Assembly Removaland

Replacement PAAssembly Removal and Replacement

To remove PA assembly:

1. Disconnect the PA RF input cable from J1.

2. Disconnect the Antenna cable from J2.

3. Disconnect the Red and Black DC input power

leads.

4. Remove the six screws securing the PA Assembly

to the rack and remove thePA assembly.

To replace the PAassembly, perform the above procedure

in reverse order.

MODULATION LEVEL

ADJUSTMENT

The MOD ADJUST control (R1 03) was adjusted to the

proper setting before shipment and should not normally re-

quire readjustment. This setting permits approximately 75

percent modulation for the average voice level. The audio

peaks which would cause overmodulation are clipped by the

modulation limiter. The limiter, in conjunction with the de-

emphasis network, instantaneously limits the slope of the

audio wave to the modulator, thereby preventing overmodu-

lation while preserving intelligibility.

TEST EQUIPMENT

1. An audio oscillator (GE Model 4EX6A10)

2. A frequency modulation monitor

3. Voltmeter

4. GE Test Set Model 4EX3A11 or 4EX8K12

5. Frequency Counter

6. Oscilloscope

7. 50 ohm Wattmeter

PROCEDURE

1. Connect the audio oscillator and the meter across

audio input terminals J10 (Green-Hi) and J11

(Black-Lo) on GE Test Set, and connect red Test

Set plug to the System red metering plug. If not us-

ing GETest Set, connect audio oscillator and meter

across P902-6 (Mike-High) through 0.5 microfarad

(or larger) DC blocking capacitor, and P902-5

(Mike-Low) on the System Board.

2. Adjust the audio oscillator for 1 Volt RMS at 1000

Hz.

3. For NPSPAC transmitters without Channel Guard

set MOD ADJUST R103 for ±4.0 kHz deviation.

4. For NPSPAC transmitters with Channel Guard, set

MOD ADJUST R103 for ±3.25 kHz deviation and

set Channel Guard MOD ADJUST R102 for ±0.75

Hz tone deviation.

Type R103 R102

Non

Channel Guard ±4.5 kHz

Channel Guard ±3.7 kHz ±0.75 kHz

NPSPAC, Non

Channel Guard ±4.0 kHz

NPSPAC,

Channel Guard ±3.25 kHz ±0.75 kHz

ICOM FREQUENCY ADJUSTMENT

First, check the frequency to determine if any adjustment

is required. The frequency should be set with a frequency

meter or counter with an absolute accuracy that is 5 to 10

times better than the tolerance to be maintained, and with the

entire radio as near as possible to an ambient temperature of

27.5°C (81.5°F).

Copyright © May 1988, General Electric Company

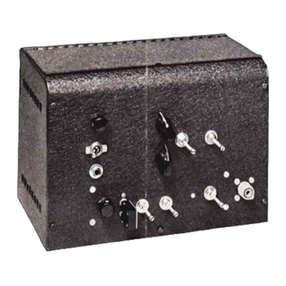

Figure 1 - Block Diagram

Component placement and connections on the printed

wire board are very critical on the PA. For this reason,

it is recommended that the entire PA assembly be re-

turned to the factory for servicing.

NOTE

The RF Power Transistors used in the transmitter

contain Beryllium Oxide, a TOXIC substance. If the

ceramic, or other encapsulation is opened, crushed,

broken, or abraded, the escaping dust may be haz-

ardous if inhaled. Be extremely careful to avoid

damaging transistors when working with thePA As-

sembly.

WARNING

LBI-31985 LBI-31985

1