RTX 1000H series user manual

K0297 Issue 2 iv

Table of Contents Page

Safety ......................................................................................................... i

Abbreviations ........................................................................................... ii

Table of Contents ..................................................................................... iv

1 DESCRIPTION ...................................................................................... 1-1

1.1 Introduction .................................................................................. 1-1

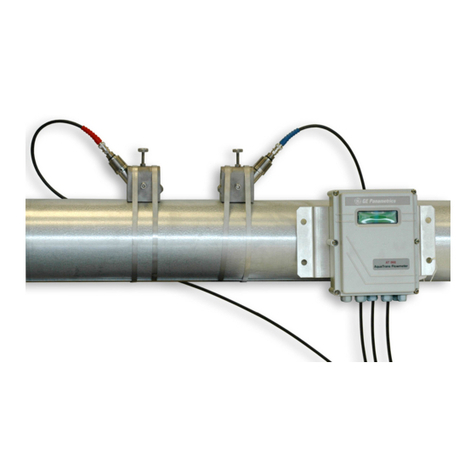

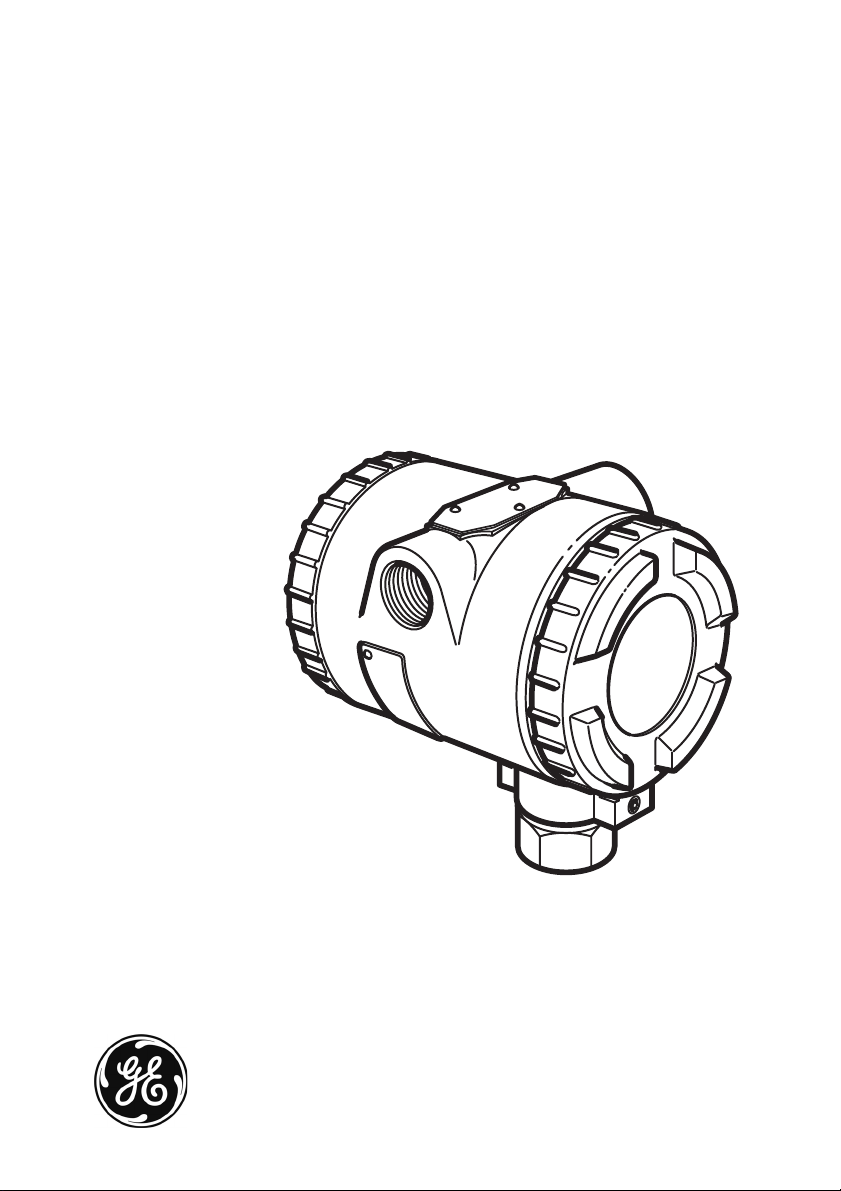

1.2 About the Electronics Housing ..................................................... 1-1

1.3 Identification Codes ..................................................................... 1-3

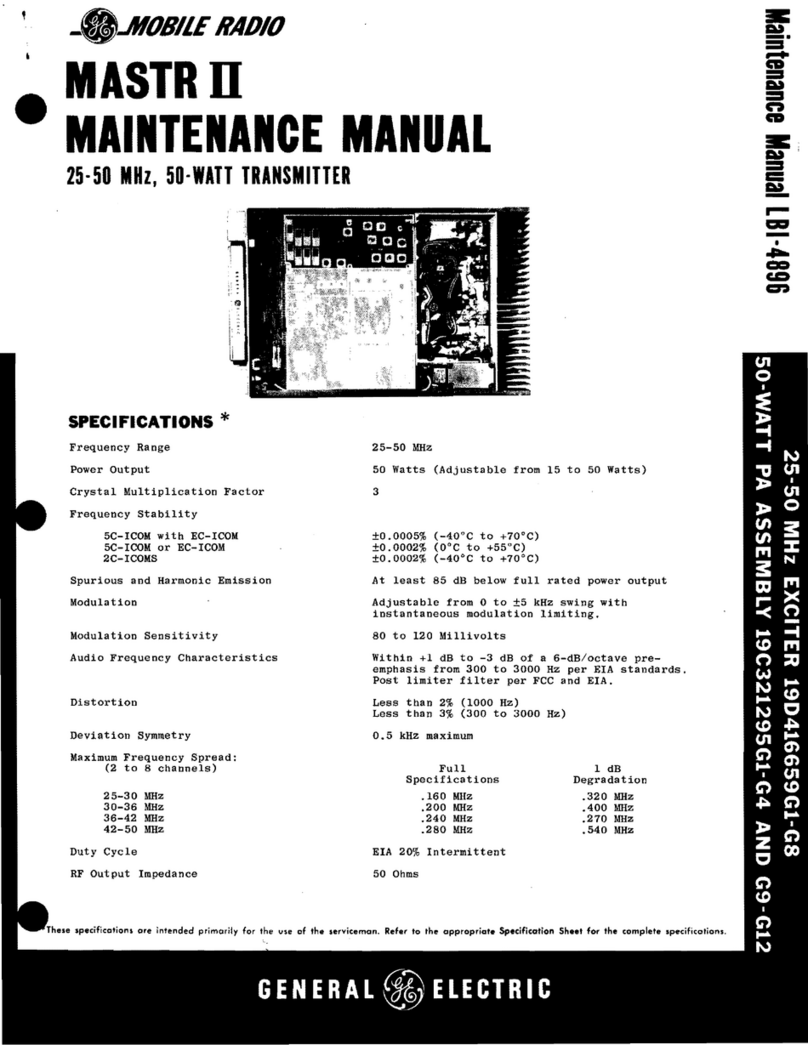

2 TECHNICAL DATA .............................................................................. 2-1

2.1 Pressure Ranges ......................................................................... 2-1

2.2 Environment Data ........................................................................ 2-1

2.3 Performance Data ........................................................................ 2-1

2.4 Physical Data ............................................................................... 2-4

3 INSTALLATION .................................................................................... 3-1

3.1 Introduction .................................................................................. 3-1

3.2 Special Tools and Equipment ...................................................... 3-1

3.3 Location and Mounting ................................................................. 3-2

3.4 To Rotate the LCD Module Thru 90° ........................................... 3-2

3.5 To Rotate the Housing ................................................................. 3-3

3.6 Impulse Piping ............................................................................. 3-3

3.7 The Transmitter Pressure Connections ....................................... 3-4

3.8 Liquid Level Measurement ........................................................... 3-6

3.9 Electrical Data .............................................................................. 3-7

3.10 System Checks ............................................................................ 3-10