Care and cleaning of the vent hood. www.GEAppliances.ca

The efficiency of the range hood system depends on the cleanliness of the intake and filters.

The frequency of cleaning required depends on the amount and type of cooking.

• Do not use the ventilating system without the filters in place or with grease-laden filters or surfaces.

These hoods have reusable metal

grease filters and drip trays. The

metal filters also help prevent

flaming foods on the cooktop from

damaging the inside of the hood.

For this reason, the metal filters

must

ALWAYS

be in place when the

hood is used.

To Clean Filters and Drip Trays

•The metal filters and drip trays

should be cleaned once a month,

or as needed.

• To clean the metal filters and

drip trays, drain and wipe all

excess grease with a dry paper

towel. Soak them and then swish

them around in hot water and

detergent. Don’t use ammonia or

ammonia products because they

will darken the metal.

• Do not use abrasives or oven

cleaners. Rinse, shake and let the

filters and drip trays dry before

replacing. They may also be

cleaned in an automatic

dishwasher.

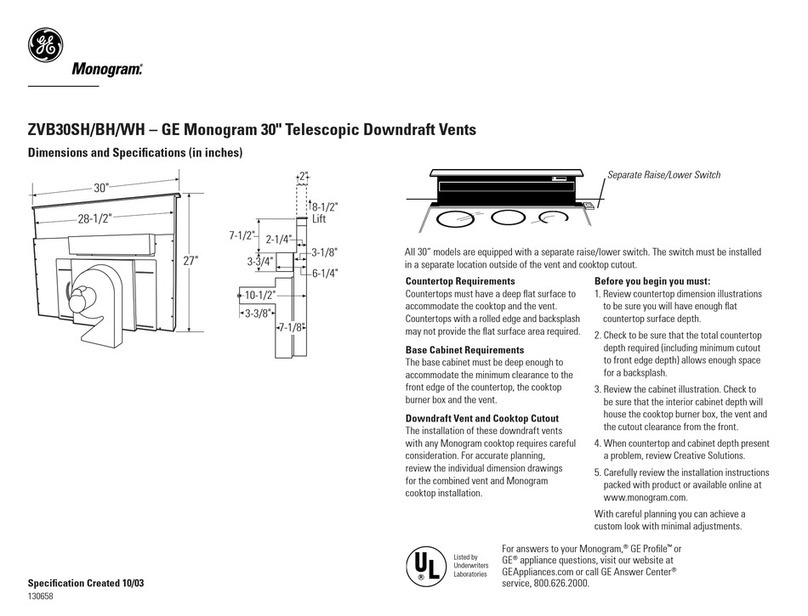

To Remove the Metal Grease Filters

and Drip Trays

• Turn the fan and lights off.

• Push each handle towards the

back and pull downwards. Fig. 1

• Unscrew the knobs that secure the

drip tray holding brackets. Fig. 3

• Grasp the drip tray and carefully

lift it up and out of the hood

track. Fig. 2

To Replace The Metal Grease Filters

• Reverse above procedure.

To Replace the Drip Trays - Figures 2-3

Place and seat the drip tray

into the hood track.

Slide trays left or right until all

trays are side by side in place

in the track.

Firmly secure the drip trays

with the the drip tray holding

brackets.

Filters and Drip Trays

To clean the hood surface, use

a hot, damp cloth with a mild

detergent suitable for painted

surfaces. Use a clean, hot, damp

cloth to remove soap.

Dry with a dry, clean cloth. Do not

use steel-wool pads or other

abrasive cleaners. They will scratch

the surface.

Anodized Aluminum Surface/Painted Surfaces

(on some models)

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Care and Cleaning

5

Do not use a steel wool pad; it will

scratch the surface.

Shake bottle well.

Place a small amount of

CERAMA BRYTE®Stainless

Steel Cleaning Polish and

Conditioner on a dry cloth

or dry paper towel.

Clean a small area

(approximately 8” x 8” or

20.3 x 20.3 cm), rubbing with

the grain of the stainless steel if

applicable.

Dry and buff with a clean, dry

paper towel or soft cloth.

Repeat as necessary.

Stainless Steel Surfaces

(on some models)

To order:

To order CERAMA BRYTE

®

Stainless Steel

Cleaning Polish and Conditioner, please call

our toll-free number:

National Parts

Centre . . . . . . . . . . . 1.800.661.1616

www.GEAppliances.ca

CERAMA BRYTE

®

Stainless Steel Cleaning

Polish and Conditioner . .. # PM10X313

WARNING

To avoid risk of fire and explosion do not use flammable liquids or solvents.

Always unplug or disconnect the appliance from the power supply before servicing.

WARNING

Be sure the entire hood (including the filters and light bulbs) has cooled and grease has

solidified before attempting to clean any part of the appliance.

Fig. 1

Fig. 2

Fig. 3