We recommend to contact the installer at least once a year for

a general inspection.

IMPORTANT: do not use pure gas, such as a lighter directly on

the sensor since the sensor could be damaged.

PERIODICAL TESTING

In case of alarm:

1) extinguish all naked flames.

2) turn off the gas supply at the gas emergency control and/or, with

a LPG supply, the storage tank.

3) do not switch on or off any electrical lights. Do not activate any

electrically powered devices.

4) Open both doors and windows to increase room ventilationIf the

alarm stops, it is necessary to identify the alarm reason and act

accordingly.

If the alarm condition continues and the cause of the leak is not

apparent and/or cannot be corrected, vacate the premises and im-

mediately notify the gas emergency service.

WARNING!

For the cleaning, use an cloth on the top. Not be opened, it could

cause damage.

Note that the sensor employed has a good resistance towards prod-

ucts such as sprays, detergents, alcohol, glues and paints.

However, these products could contain substances which, if in great

quantity, could interfere with the sensor and cause false alarms.

We recommend to ventilate the room should products like these be

used.

Note that the detector is not able to detect gas leaks occurring outside

the room where it is installed, neither inside walls nor under the floor.

To make gas (methane and LPG) nose identifiable, gas is added with

a particularly disturbing smelling substance.

Small gas quantities coming out from left open cookers for some min-

utes do not cause the gas detector alarm signalling even if it is clearly

nose perceptible; in fact the quantity of gas presents in the environ-

ment can be under the alarm threshold.

Please remember that the gas detector cannot work without power

supply.

3

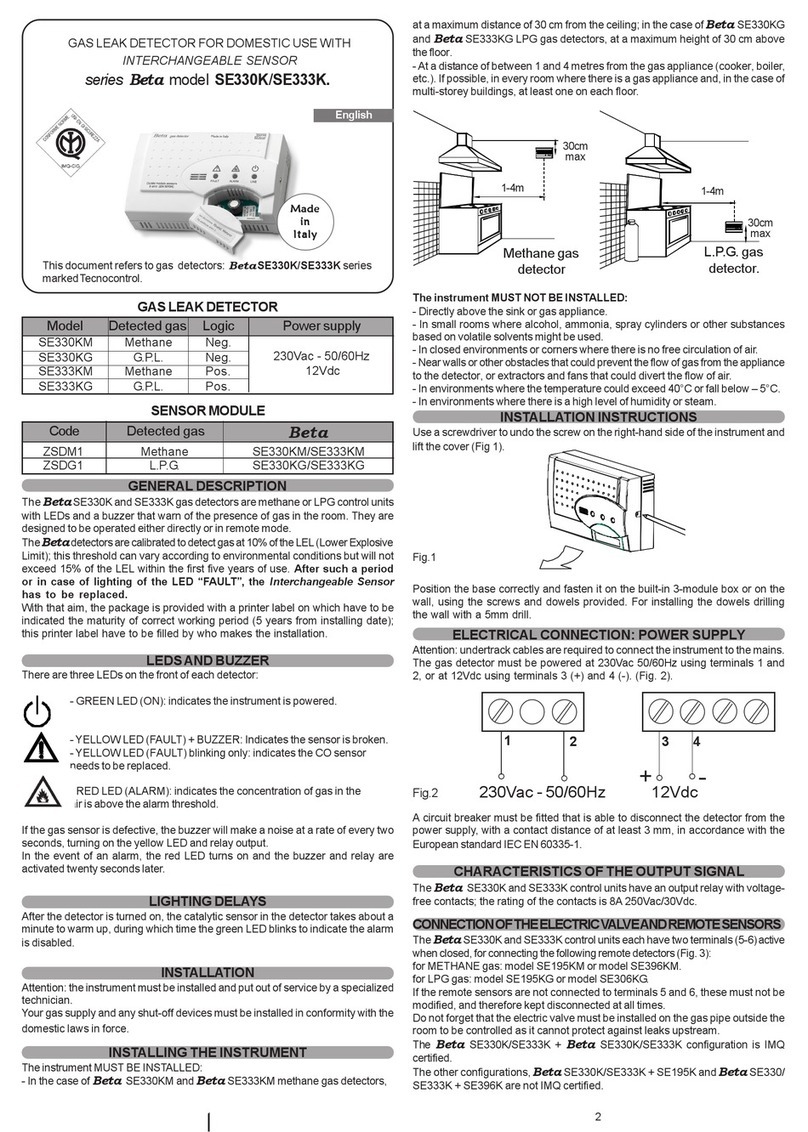

OPERATIONAL WITH NORMALLY OPENED VALVE (N.O.)

FIG. 3

OPERATIONAL WITH NORMALLY CLOSED VALVE (N.C.)

LOWER EXPLOSIVE LIMIT (L.E.L.)

The use of different systems from the calibration gas sample cylinder,

makes it impossible to verify the proper functioning of the sensor.

Even when you want to recreate the actual conditions of danger for

which protection the gas sensor is installed, this is inapplicable.

As an example, the supply of gas from the normal home kitchen equip-

ment.

Our detectors are calibrated at 10% LEL (Lower Explosive Limit).

The explanation is simple: lets suppose to have a kitchen measuring 3

meters. wide by 4 meters in length, and with height of 3 meters.

- The volume of the kitchen is equivalent to 4 x 3 x 3 that is 36 m3,

equal to 36,000 Lt.

When 4,4% of the volume of the kitchen, is filled of natural gas, in the

room a dangerous mixture is created.

- This 4,4% is called L.E.L (Lower Explosive Limit).

- In our case a 4,4% of 36.000Lt correspond to 1584Lt. (L.E.L.).

- Our detectors, according to the IMQ approvals operate at 10% of

the LEL, then 10% of the value of 1584Lt, that in this case is 158,4LT,

THEREFORE ONE THENTH OF THE LOWER EXPLOSIVE LIMIT

(L.E.L.)

Taking into consideration the fact that the house cooker has a gas noz-

zle of a few tenths of a millimetre and that the gas pressure is of a few

millibars, the gas flow would allow the delivery of 158,4 litres of gas

(sufficient to make the sensor react) only after hours.

Even with broader gas supply sources, the peculiar and strong smell

of natural gas, makes impossible the human presence and it make evi-

dent the serious danger situation even when the natural gas saturation

is still too little to allow the explosion.

FIG. 3

CONTROLLO FUNZIONAMENTO - (TEST)

After the installation it is possible to check the correct

operational of the instrument by pushing for at least 2

seconds the TEST button on the board, in this way all the

leds will be alight, the acoustic alarm and both relays will

be on for 5 second.

At this point it will be necessary to rearm the electro valve

connected.

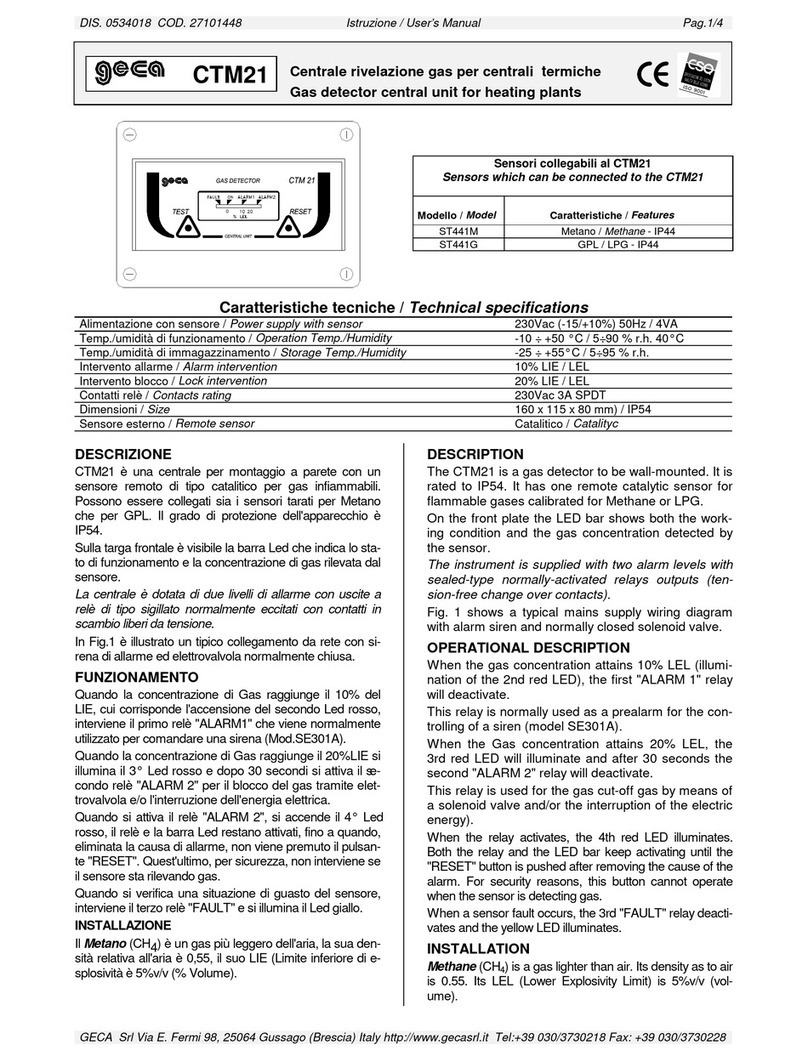

230Vac-50/60Hz

SE235

NC COM NO

L N

FIG. 4

230Vac-50/60Hz

SE235

NC COM NO

L N

Normally Close

Valve

Normally Open

Valve

At this point it will be necessary to rearm the electro valve connected.

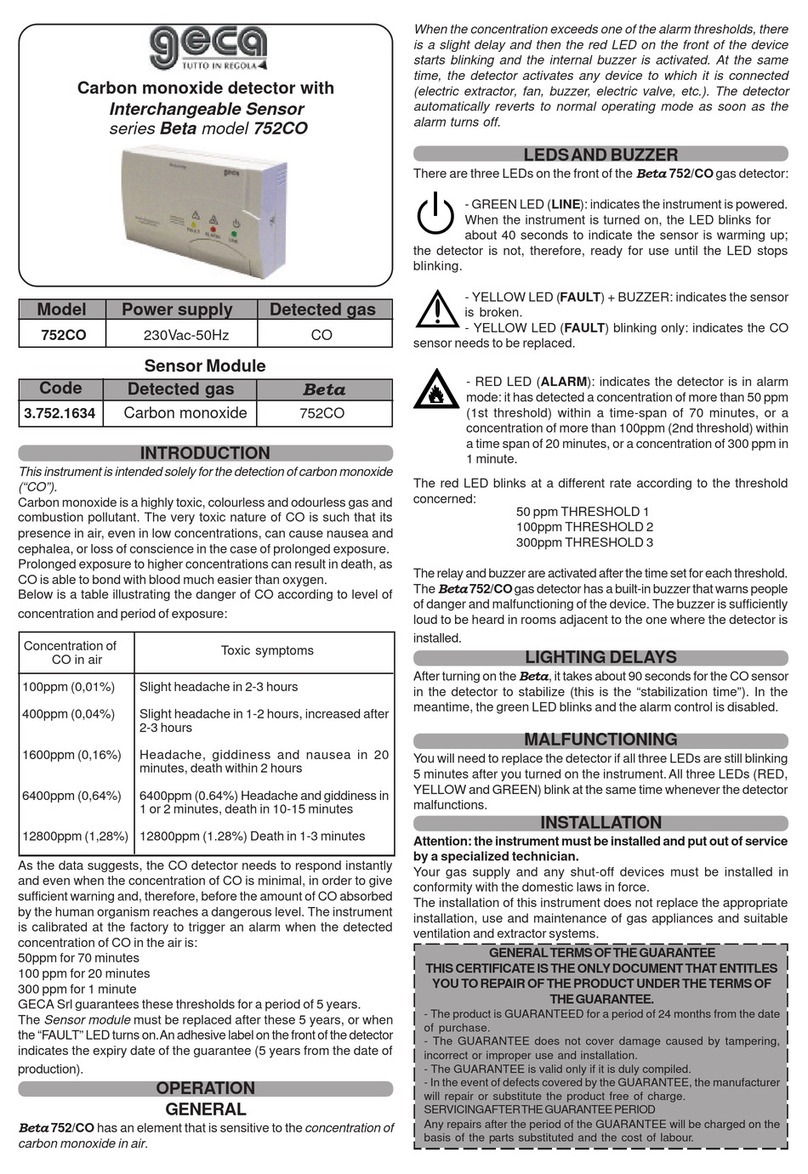

It is also possible to add a second TEST button simply by connecting

a new button to the terminals of (Fig.5).

The new TEST button will then be positioned at your convenience.

FIG. 5

SE235

NC COM NO

L N

TEST

T: 09 636 1401 | E: sales@systemcontrol.co.nz | W: systemcontrol.co.nz

In support of our policy of continuous product improvement we reserve the right to change materials and specifications without notice.

Drawings, where used, are not to scale. All dimensions are in millimetres and sizes given are approximate. Where possible, technical MSDS

data sheets are made available on the website. All products should be installed and used in accordance with manufacturer’s instructions

provided. Warning: products may be the subject of registered designs and patents. Refer to website for terms and conditions on warranty.