1200/1300

CONTROLLER

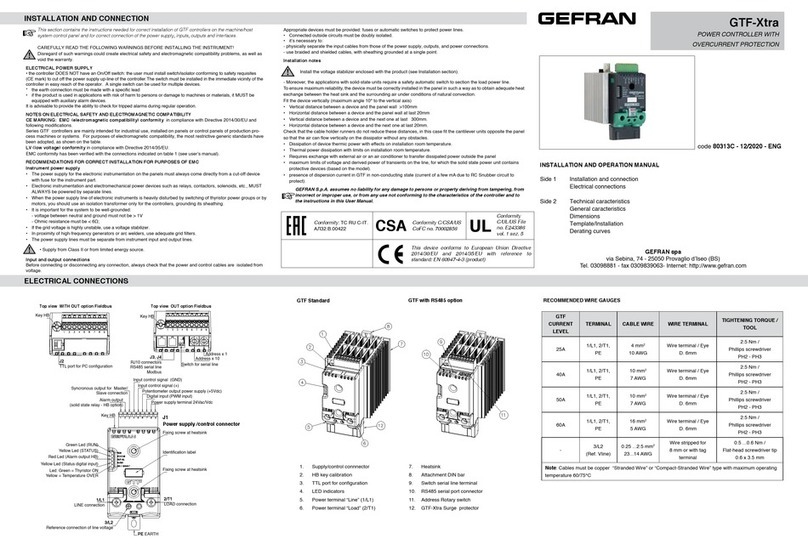

cod. 80309 - 01/2014 - ENG

1 • DIMENSIONS AND CUT-OUT; PANEL MOUNTING

This section contains the instructions necessary for

correct installation of the 1200/1300 controllers into the

machine control panel or the host system and for correct

connection of the controller power supply, inputs, outputs

and interfaces.

Before proceeding with installation read the

following warnings carefully!

Remember that lack of observation of these warnings

could lead to problems of electrical safety and

electromagnetic compatibility, as well as invalidating

the warranty.

Electrical power supply

• the controller is NOT equipped with an On/Off switch: the user

must provide a two-phase disconnecting switch that conforms

to the required safety standard (CE marking), to cut off the

power supply upstream of the controller.

The switch must be located in the immediate vicinity of the

controller and must be within easy reach of the operator. One

switch may control more than one controller.

• if the controller is connected to NOT isolated electrical

equipment (e.g. thermocouples), the earth connection must be

made with a specific conductor to prevent the connection itself

from coming directly through the machine structure.

• if the controller is used in applications with risk of damage to

persons, machinery or materials, it is essential to connect it up

to auxiliary alarm equipment. It is advisable to make sure that

alarm signals are also triggered during normal operation.

The controller must NOT be installed in flammable or explosive

environments; it may be connected to equipment operating

in such atmospheres only by means of appropriate and

adequate types of interface, conforming to the applicable safety

standards.

Notes Concerning Electrical Safety and

Electromagnetic Compatibility:

CE MARKING:

The instrument conforms to the European Directives 2004/108/

CE and 2006/95/CE with reference to the generic standards:

EN 61000-6-2 (immunity in industrial environment) EN 61000-6-3

(emission in residential environment) EN 61010-1 (safety).

Series 1200/1300 temperature controllers are mainly designed to

operate in industrial environments, installed on the switchboards

or control panels of productive process machines or plants.

Advice for Correct Installation for EMC

Instrument power supply

• The power supply to the electronic equipment on the

switchboards must always come directly from an isolation

device with a fuse for the instrument part.

• The electronic instruments and electromechanical power

devices such as relays, contactors, solenoid valves, etc., must

always be powered by separate lines.

• When the electronic instrument power supply is strongly

disturbed by the commutation of transistor or power units

or motors, an isolation transformer should be used for the

controllers only, earthing the screen.

• It is essential that the plant has a good earth connection:

- the voltage between neutral and earth must not be >1V

- the Ohmic resistance must be <6W;

• If the mains voltage fluctuates strongly, use a voltage stabilizer.

• In the proximity of high frequency generators or arc welders,

use adequate mains filters.

• The power supply lines must be separate from the instrument

input and output ones.

Inputs and outputs connection

• The externally connected circuits must be doubly isolated.

• To connect the analogue inputs (TC, RTD) the following is

necessary:

- physically separate the input cables from those of the power

supply, the outputs and the power connections.

- use woven and screened cables, with the screen earthed in

one point only

• To connect the regulating and alarm outputs (contactors,

solenoid valves, motors, fans, etc.), fit RC groups (resistance

and condensers in series) in parallel to the inductive loads that

operate in Alternating Current.

(Note: all the condensers must conform to VDE (class X2)

standards and withstand a voltage of at least 220V AC. The

resistances must be at least 2W).

• Fit a 1N4007 diode in parallel with the coil of this can be

removed inductive loads that operate in Direct Current.

GEFRAN S.p.A. declines all responsibility for any

damage to persons or property caused by tampering,

neglect, improper use or any use which does not

conform to the characteristics of the controller and to

the indica tions given in these Instructions for Use.

Warnings and instructions for mounting to the panel

Instructions for installation category II, pollution

level 2, double isolation.

• only for low power supply: supply from Class 2 or low voltage

limited energy source.

• the power supply lines must be separate from the controller

input and output ones

• group the instruments together keeping them separate from the

powered part of the relay

• do not install high-power remote switches, contactors, relays,

thyristor power units (especially the “phase angle” type),

motors, etc. in the same switchboard

• avoid dust, humidity, corrosive gasses and heat sources

• do not block the ventilation holes: the working temperature

must be between 0...50°C

• surrounding air: 50°C

• use 60/75°C copper (Cu) conductor only, wire size range 2x No

22 - 14AWG, Solid/Stranded

• use terminal tightening torque 0.5N m

Nominal ambient conditions

Before supplying the Controller with power, make

sure that the mains voltage is the same as that

shown in the last number of the order code.

2 • INSTALLATION & CONNECTION

3 • DESCRIPTION OF FACEPLATE

4 • CONNECTIONS

PWR

Outputs

Out1 - Out2

Inputs

Serial line

Digital inputs /

CT Input

Outputs

Out3 - Out4

1200

Always make the connections using cable types suitable for

the voltage and current limits given in Section 5 - Technical

Specifications.

If the Controller has faston terminals these must be protected and

isolated.

If it has screw terminals, the wires must be attached, at least in pairs

Power Supply

Inputs

+

24V

4..20mA

VT +

+

+

S

24VVT +

+

+

+

Standard:

100...240Vac/dc ±10% , max 18VA

Optional:

11...27Vac/dc ±10%, max 11VA 50/60 Hz

Available thermocouples:

J, K, R, S, T

(B,E, N, L, U, G, D, C

possible by inserting a

custom linearization)

- Observe polarities

- For extensions, use the

correct compensating cable

for the type of TC used

Connect for

0/4..20mA

input

Jumper S3 closed on

CPU board (see CAP.

6 Maintenance)

Linear input in

Direct Current

0/4..20mA, Ri = 50W

TC Input Linear input with 3-wire transmitter

supplied from the instrument

Linear input with 2-wire

Transmitter supplied from the

instrument

~

PWR

Linear input (I)

Inputs

+

Linear input in

Direct Current

60 mV, 1V (Ri > 1MW)

5V, 10V (Ri > 10KW)

Linear input (V) PTC/NTC/Pt100/JPT100 input

T

Jumper S2 closed

on CPU board

(see CAP. 6

Maintenance)

Use wires of

adeguate diameter

(min. 1mm2)

2-wire connection 3-wire connection

Outputs Out1, Out 2 User configurable generic outputs

C

NO

NC - Relay 5A

250Vac/30Vdc

NC not

available if

Out2 is triac

type

Out 1

-

+

C

NO

- Relay 5A

250Vac/30Vdc

-Logic 24V

(10V a 20mA)

Out 2

~

~

load

Triac

20...240Vac,

max. 1A ± 10%

Out 2

Outputs Out3, Out 4 User configurable generic outputs

Out3

+

- Relay 5A 250Vac/30Vdc

- Logic 24V 10V a 20mA

- Direct 0...10V, 0/4...20mA

- Analogue 0...10V, 0/4...20mA

- 0/2...10V (S1-ON),

0/4...20mA (S1-OFF)

S1 is a jumper on the board

for continuous or analogic

output

Out 3

Out4

+

- Relay 5A 250Vac/30Vdc

- Logic 24V (10V a 20mA )

Out 4

T

S1

Digital inputs / CT Input User configurable generic inputs

IN2

IN1

COM

Digital input 24V 5mA

(Jumpers S1, S2 in position P)

or from non-powered terminal

(Jumpers S1, S2 in position N)

Hrd Menù configuration

Parameter diG or di2 = +16

IN1, IN2 digital inputs

TA

IN1

COM

- Input from current transformer

50mAac, 10W 50/60Hz

- Digital input 24V 5mA

(Jumpers S1, S2 in position P)

or from non-powered terminal

(Jumpers S1, S2 in position N)

Hrd Menù configuration

Parameter diG or di2 = +16

CT, IN1 inputs

S1

S2

NPS1

S2

NP

1200

A

1300

A

For correct and safe installation, follow the instructions and observe the warnings contained in this manual.

(A) panel fixing brackets

Panel mounting:

To fix the unit, insert the brackets provided into the seats on either side of the case.

To mount two or more units side by side, respect the cut-out dimensions shown in the drawing.

Serial line

(data +)

(data -)

GND

B

A

RS485 isolated serial line

Modbus 2 wires (Standard)

Tx

+

Rx

+RS485 isolated serial line

For configuration

Modbus 4 wires/Cencal.

Modbus 4 wires / Cencal

S1 S1

ID Symbol Function

PV : Shows the process variable, the menu identification, the parameters identification and the error codes

SV : Shows the setpoint value, the value of the parameter displayed in PV and three dashes (- - -) when PV contains a menu

heading

Increases/Decreases the value of the parameter displayed in SV until the max/min. value is reached.

Held down: progressively increases the speed of increasing/decreasing the value displayed in SV.

Used to move between the various menus and parameters of the controller.

Confirms the value of the current parameter (or parameter edited using ) and selects the next parameter.

Button with configurable function: with standard configuration commutes the

controller operating mode (MANUAL/AUTOMATIC).

Is only on when the display shows the process variable.

(for configuration see parameter BVT in the KRD menu) )

+Confirms the value of the current parameter (or parameter edited using ) and selects the previous parameter.

Output status indicators:

OUT1 (AL1), OUT2 (Main), OUT3 (HB), OUT4

Function indicators: with standard configuration they show

the controller operating status.

For configuration see parameter LD.1, LD.2, LD.3 in the KRD

L1 MAN/AUTO = OFF (automatic control)

ON (manual control)

L2 SETPOINT 1/2 = OFF (IN1= OFF local Setpoint 1)

ON (IN1=ON local Setpoint 2)

L3 SELFTUNING = ON (Self activated)

OFF(Self deactivated)

INSTALLATION AND OPERATION MANUAL

Side 1 1 Dimensions and cut-out; panel mounting

2 Installation and connection

3 Description of faceplate

4 Connections

Side 2 5 Technical specifications

6 “Easy” programming and configuration

7 Quick start guide

The complete manual is available for download from the

website www.gefran.com

GEFRAN spa reserves the right to make any aesthetic or

functional change at any time and without notice.

Altitude Up to 2000m

Working/storage

temperature 0..50°C/-20...70°C

Non condensing

relative humidity 20...85%