Page 2

GENERAL DESCRIPTION

Gemtor D-Ring Anchors are designed for use where a temporary or permanent, stationary

anchorage connector is required. The Model AD-1 or AD-2 attaches quickly and easily to structures

capable of supporting at least 5000 lbs. such as the bottom or side of horizontal and vertical beams

and columns to form a rigid anchorage connector to connect a safety lanyard, retractable lifeline,

vertical and horizontal lifelines or perimeter lines for personal fall protection and fall restraint.

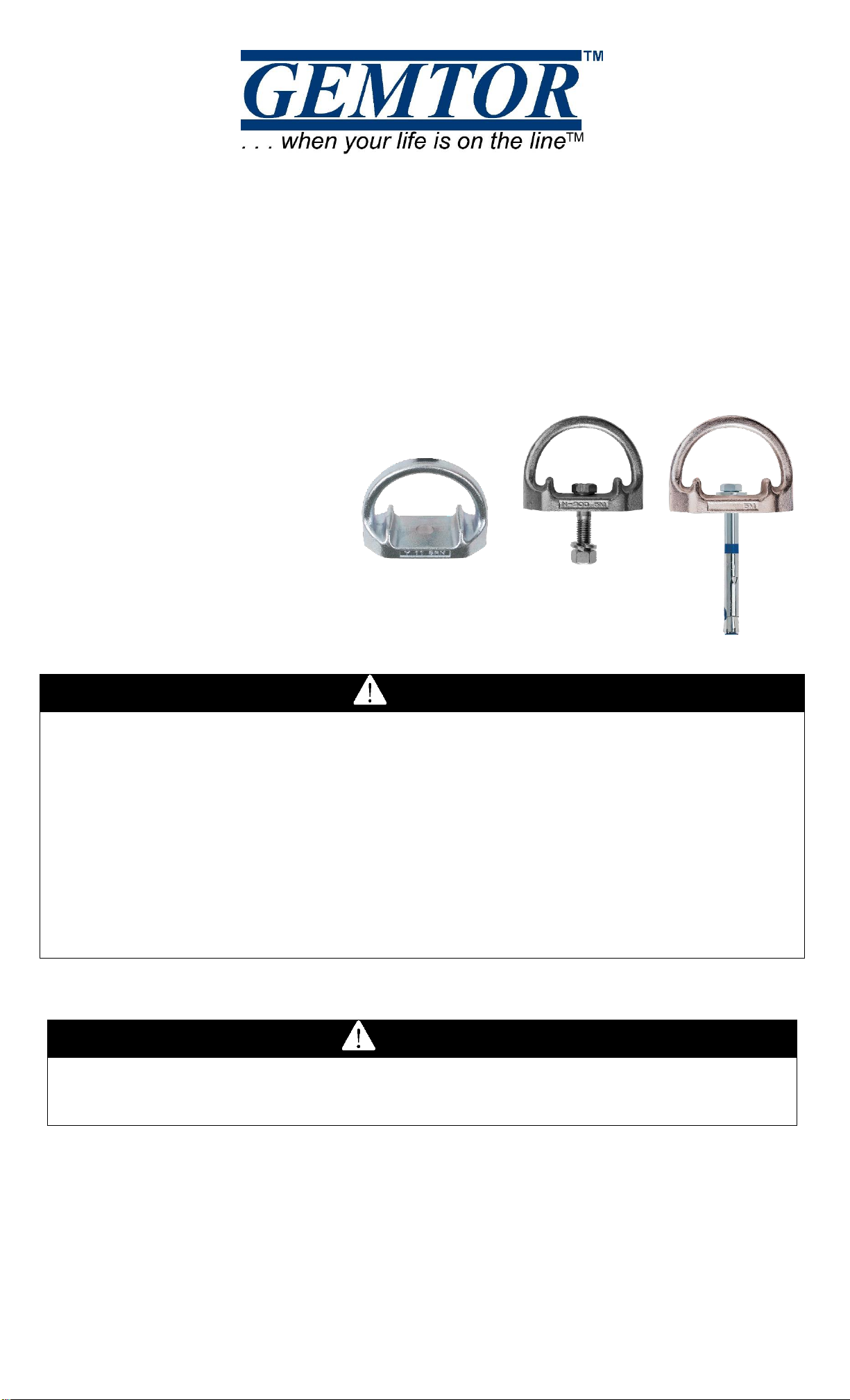

AVAILABLE MODELS

All models are constructed of zinc plated drop-forged alloy steel.

AD-1 –Supplied with 1/2” grade 8 bolt and nut and washer.

AD-1C –Supplied with 1/2” X 4 ¾” concrete expansion bolt.

AD-2 –Anchor without mounting hardware, provided with 1/2” mounting hole.

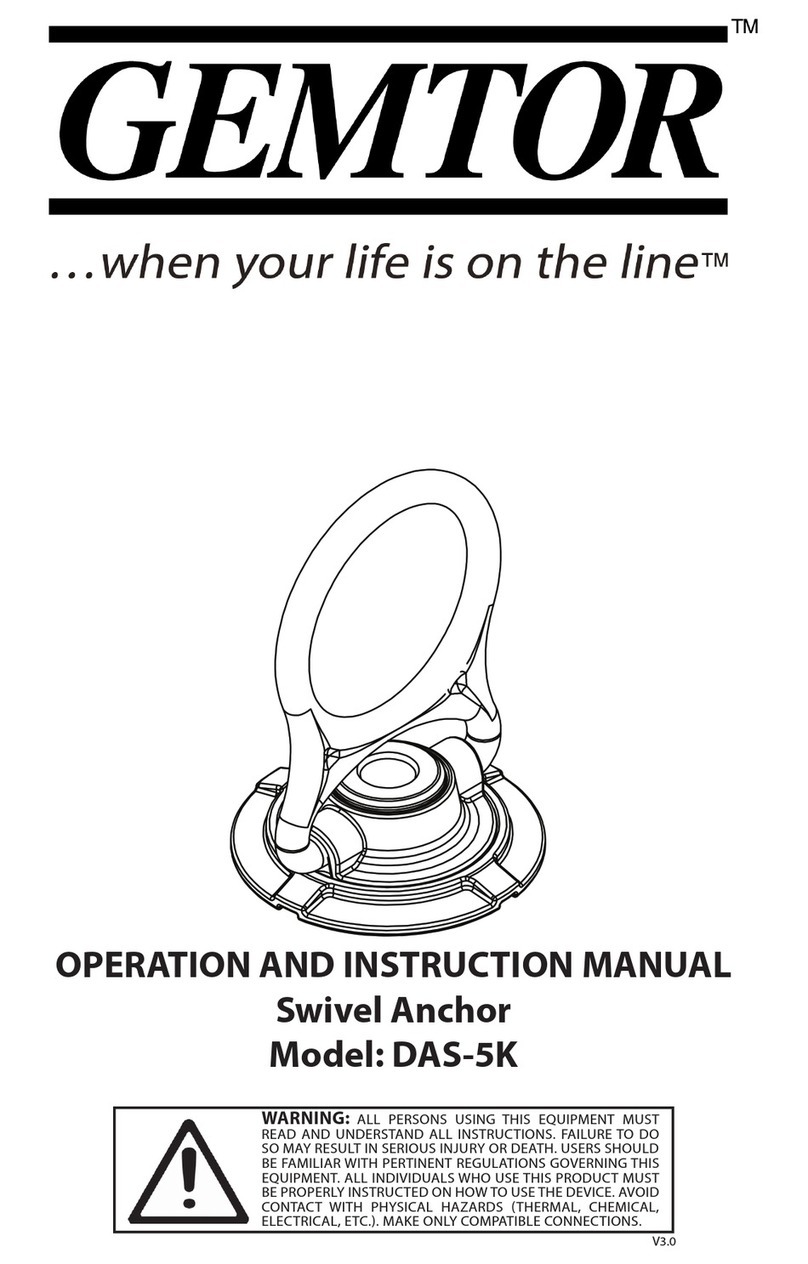

DAS-5KCKIT –Mounting kit for concrete. Compatible with AD-2 and DAS-5K

WARNINGS AND LIMITATIONS

•Always follow all requirements of the Occupational Safety and Health Act (OSHA) and all state

and local regulations.

•If using a snaphook for connection to the Connection Point on the D-ring anchor, always make

sure that the snaphook gate cannot contact the beam in a way that could put pressure on the

gate and cause it to open.

•Always calculate the fall distance and ensure that a clear, unobstructed distance is provided

under the beam to which the worker is attached (Remember to allow for system elongation and a

safety margin).

•Develop a rescue plan establishing what to do if a fall occurs.

•Equipment must be used by properly trained personnel only.

•The employer shall provide a training program for each employee who might be exposed to fall

hazards. The program shall enable each employee to recognize the hazards of falling and shall

train each employee in the procedures to be followed in order to minimize these hazards.[OSHA

1926.503(a)(1)]. In addition, training shall include; fall protection basics, proper use of all

applicable fall protection equipment and proper handling, maintenance and storage of the

equipment.

•Never use the D-ring anchor for anything other than its intended use.

•The suitability of this device for the intended use must be determined prior to use and is the sole

responsibility of the employer.

•Before each use, visually inspect for physical damages, wear and corrosion. Check the beam

anchor for damage, cracks, wear, corrosion, or malfunctioning parts. Inspect each system

component in accordance with its associated operation and instructions manual. If the inspection

reveals a problem or an ineffective condition, remove the unit from the service.

•A qualified person shall inspect the beam anchor at regular intervals. Units that do not pass

inspection shall be returned to Gemtor immediately for repair, satisfactory inspections should be

marked on the provided inspection log.

•Units subjected to fall arrest forces shall be immediately removed from service and not used

again until the anchor is inspected by a qualified person.

•Make sure that all system components are compatible and that potential impact forces, freefall

distances, and deceleration distances are within the allowances of applicable regulations.

•A full-body harness with attachment in the center of the wearer’s back at or above shoulder level

must be used for fall arrest.

•Use only Grade 8 or other Gemtor approved hardware.

•Ensure that the structural member and installed anchor to which the worker is attached is capable

of sustaining the fall arrest forces (5000 lbs. or twice the potential impact when designed,

installed, and used under the supervision of a qualified person).

•One worker only! Never attach more than one worker to beam anchor.

•Free fall distance shall not exceed 6 ft.

•Do not try to adjust, repair or modify any Gemtor product. For prompt service, please contact:

Gemtor, Inc., One Johnson Ave., Matawan, NJ 07747, 800-405-9048.

•Attach this device at or above the connection point on your harness whenever possible. If this

device is connected below the attachment point, you must ensure that the system is designed for

this type of attachment, can withstand the potential impact forces and can absorb a sufficient

amount of fall arrest force.

•D-ring anchor must be installed flush on surface. This may require the use of a wedge washer on

S-type (Structural I-beams) or similar structures.