Installation & Operation Manual Copyright © Puretec Pty Ltd 2018

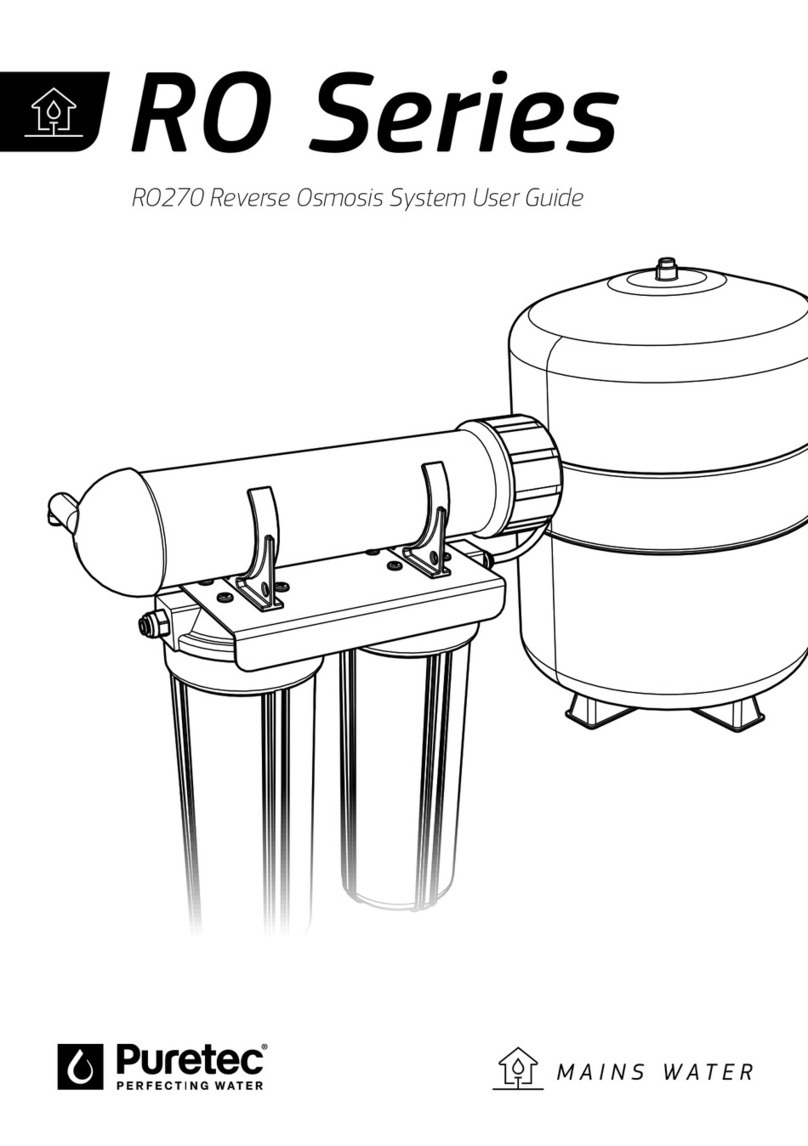

Step 5: Install RO Assembly

The RO Assembly includes the following components: sumps (3), support leg, prelter, RO

membrane elements (2), and postlter. The tubing is attached to the manifold by the elbow

connectors. When choosing a location for the system, allow enough tubing for it to be moved for

periodic servicing of the lters and membrane elements (Figure 6 RO Assembly).

Figure 6

NOTE: Make sure the tubing is pushed past the O-rings for a

secure fit. Also, when replacing any tubing, cut tubing

back ~1/4 inch prior to re-inserting to prevent leaks.

INSTALLATION cont.

Step 4: Make Tubing Connections

The connections to the faucet should be complete, the remaining

connections are:

• Feed connection—clear tubing from feed valve to white elbow

connector

• Drain connection—either red tubing from the air gap or black

tubing from grey elbow connector will attach to the drain

adapter

• Permeate connection—blue tubing from faucet to blue elbow

connection

• Attach the fittings to the manifold

A typical connection is shown in Figure 7 Side View and Cutaway of

Tubing Fitting.

NOTE: For optimal system performance, we recommend using tubing

lengths that are as short as possible.

Postfilter

Install the postfilter in line with the blue permeate tubing. Make sure

flow direction aligns with water path. Secure tubing with collet lock

clips.

Drain Adapter (Optional)

The drain adapter has a rubber inlet that accepts the 3/8-inch black

drain tube or the 1/2-inch red tube. The 3/8-inch black tubing will

connect here if the faucet is not using the air gap module.

When the tubing is in position, use the supplied hose clamps to

secure the connection.

NOTE: When sliding tubing into the drain adapter inlet, wet the

tubing. Water will help the tubing slide into the rubber inlet.

Feed Pressure Gauge

The supplied pressure gauge can be connected to the feed line to

monitor system feed pressure. For proper system performance, the

dynamic feed pressure must be between 40 psi (2.76 bar) and 80 psi

(5.52 bar) when the system is in operation.

The feed pressure gauge is intended for use only during

installation and troubleshooting of the RO system. The

pressure gauge should be removed during normal system

operation because some regulatory agencies did not

evaluate the RO system with the feed pressure gauge in

place.

Step 5: Install RO Assembly

The RO Assembly includes the following components: sumps (3),

support leg, prefilter, RO membrane elements (2), and postfilter. The

tubing is attached to the manifold by the elbow connectors. When

choosing a location for the system, allow enough tubing for it to be

moved for periodic servicing of the filters and membrane elements

(Figure 8 RO Assembly).

Do not attempt to mount/hang the system. Do not

try to drill mounting holes anywhere on the system.

If putting above ground/cabinet level, a sturdy,

permanent shelf is recommended.

O-Ring

O-Ring

Collet

Tubing

Collet

Lock Clip

Figure 7 Side View and Cutaway of Tubing Fitting

Figure 8 RO Assembly

WARNING: Do not attempt to mount/hang the system. Do not try to drill mounting holes

anywhere on the system. If putting above ground/cabinet level, a sturdy, permanent shelf is

recommended.

Recommended Placement Positions

The RO assembly should be positioned in one of two ways.

The rst position is with the unit standing upright using the support leg with the sumps

horizontal. The tubing is directed to provide the best t.

The second position, sets the unit on end so the sumps are pointing up. The tubing is directed

upward and the locking bar is down to lock the tubing connections. See Figure 7 system

positions.

Note: Ensure that the support leg is installed on the sumps.

Figure 7

Recommended Placement Positions

The RO assembly should be positioned in one of two ways.

The first position is with the unit standing upright using the support

leg with the sumps horizontal. The tubing is directed to provide the

best fit.

The second position, sets the unit on end so the sumps are pointing

up. The tubing is directed upward and the locking bar is down to lock

the tubing connections. See Figure 9 System Positions.

NOTE: Ensure that the support leg is installed on the sumps.

Connection Lubrication

Connections with O-rings must be properly lubricated. The following

instructions describe the method and locations for lubrication.

Six packets of silicone lube are supplied. One packet should be

completely used to lubricate the O-ring contact surfaces in the 3

manifold ports and 2 RO membrane locations (Figure 10). Follow

Figure 11 and lubricate the filter seat and the flat surface below the

threads for the 3 sump locations. Use a complete packet of silicone

for each sump location.

NOTE: To properly lubricate the O-ring contact area, a film of clean

silicone grease is applied. The film should cover all of the

surface area that the O-ring will slide over and seal with. Do

not use grease containing petroleum products.

INSTALLATION cont.

Figure 9 System Positions

First Position

Locking Bar

Second Position

Support Leg