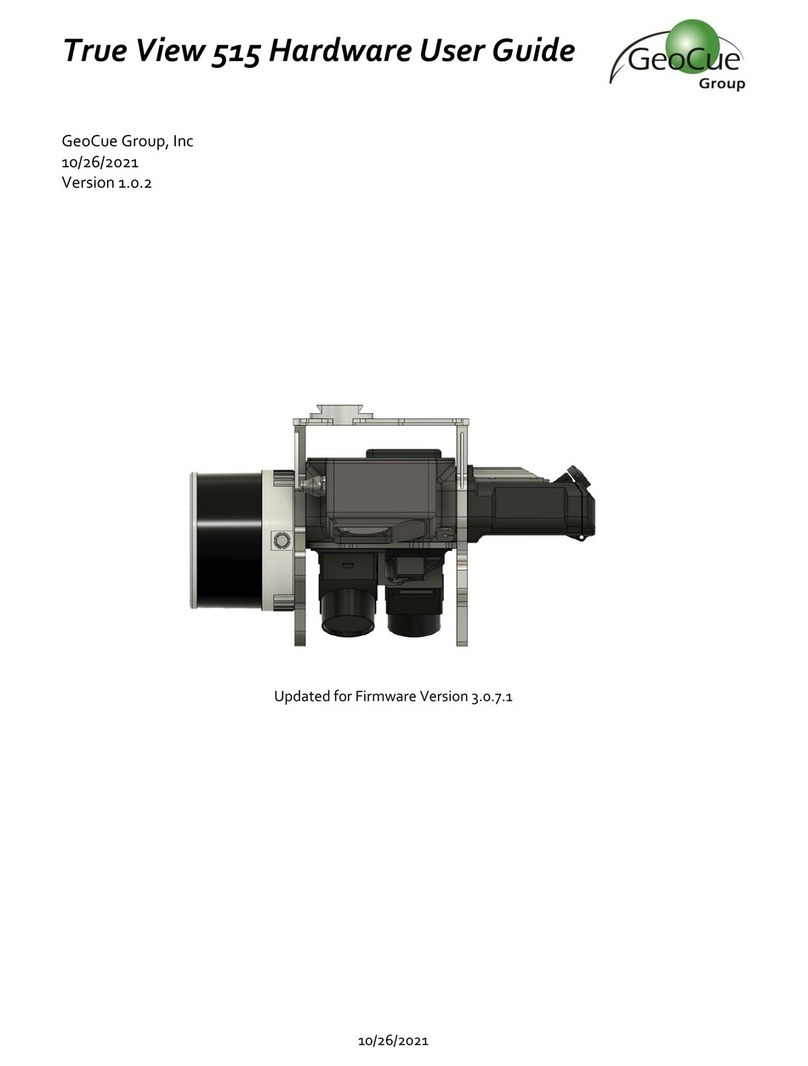

True View 615/620 Hardware User Guide

2 True View 615/620 Hardware User Guide 12/21/2020

Contents

About GeoCue Group, Inc. ......................................................................................................................4

About True View® 615/620 ..................................................................................................................... 5

A True View Cycle ................................................................................................................................... 5

True View 615/620 Hardware Integration Kit ..........................................................................................6

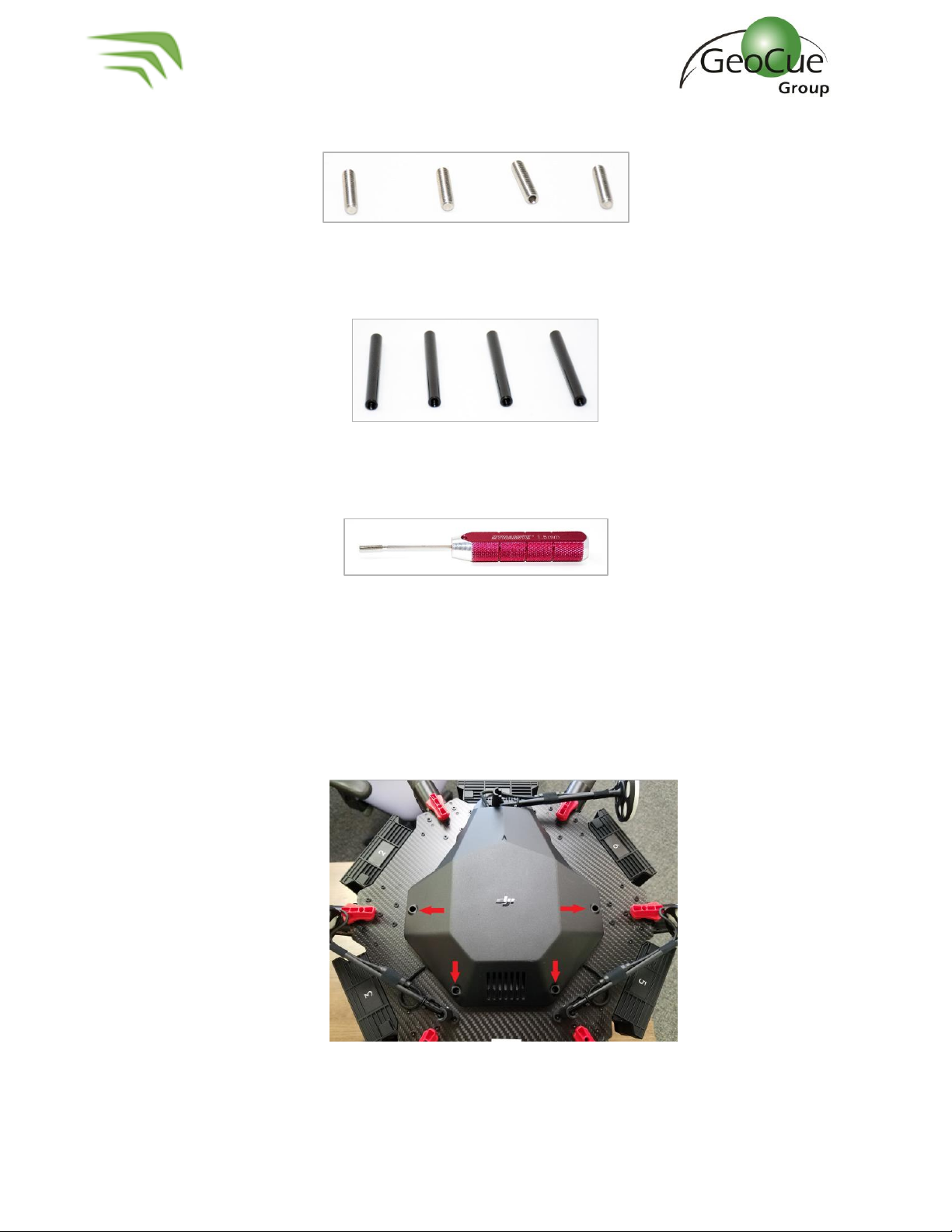

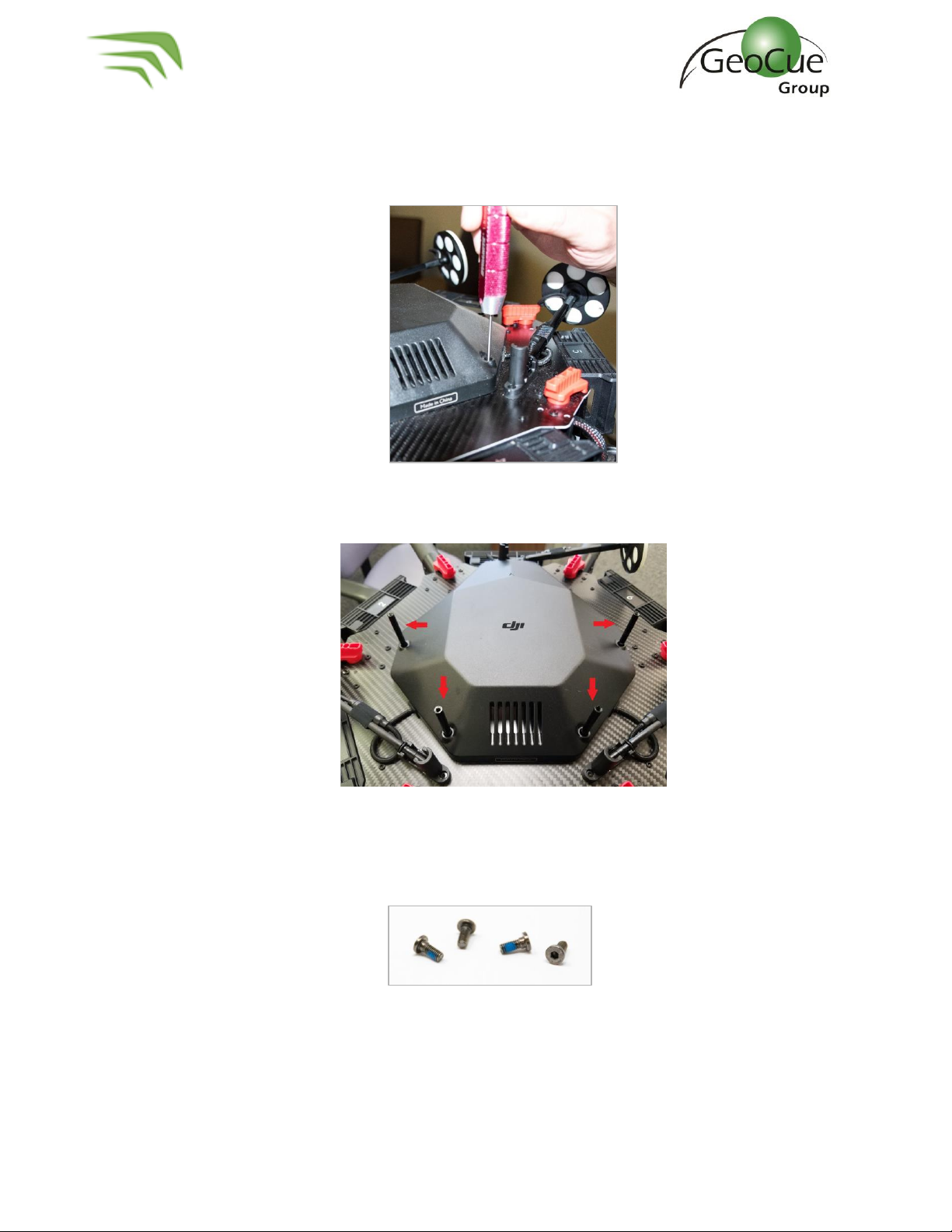

Installing the Top Plate and Controller Box .........................................................................................6

Installing the Ronin Mount ................................................................................................................ 10

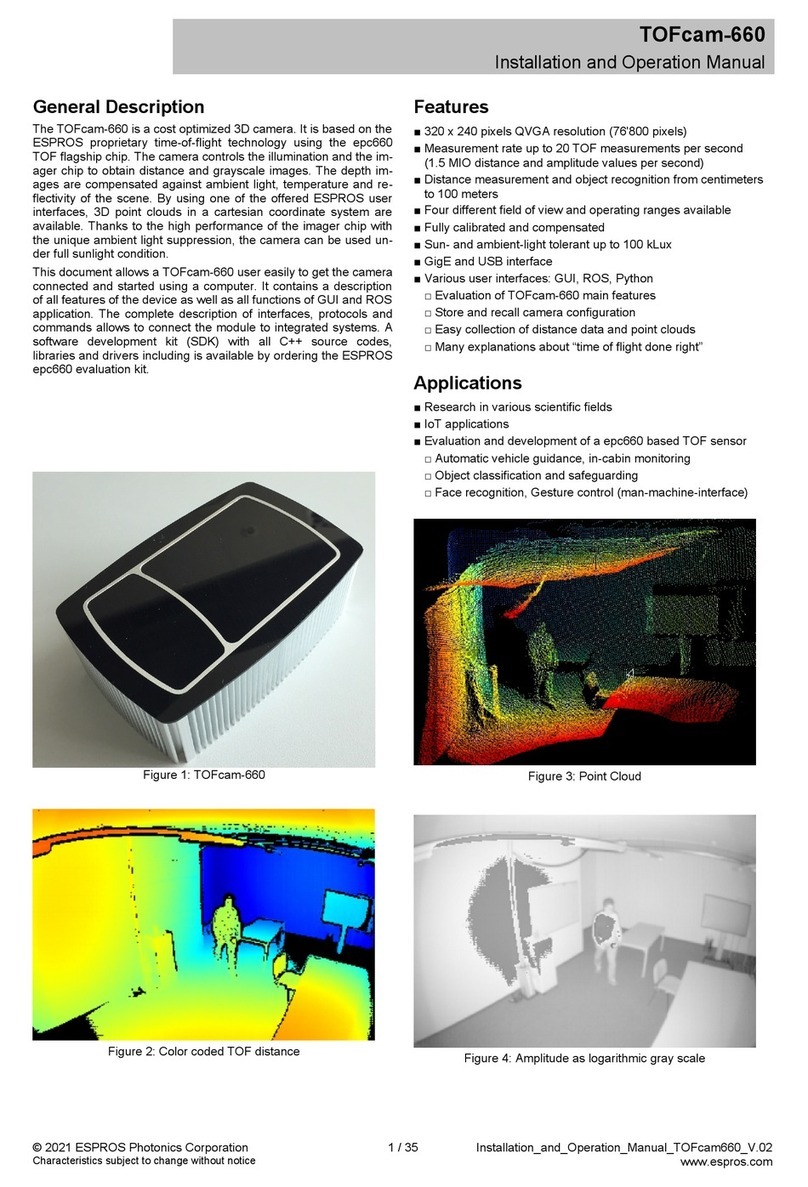

True View 615/620 Installation.............................................................................................................. 12

True View Battery ................................................................................................................................. 16

True View USB Mass Storage (UMS)......................................................................................................17

System Configuration File (SCF).........................................................................................................17

Core Configuration File (CCF).............................................................................................................17

CCFSection6 –POS ....................................................................................................................... 18

CCFSection8 –Camera.................................................................................................................. 18

CCFSection11 –Configuration Laser.............................................................................................. 19

CCFSection15 –Battery.................................................................................................................20

CCFSection16 - Cycle .................................................................................................................... 21

CCFSection17 –Storage Auto Delete ............................................................................................ 22

True View 615/620 Field Operations...................................................................................................... 23

1. Base Station .............................................................................................................................. 23

2. Pre-Flight ..................................................................................................................................24

3. Controller Box LEDs ..................................................................................................................26

4. Heading Alignment Maneuver...................................................................................................28

5. After Landing ............................................................................................................................29

True View EVO...................................................................................................................................... 30

Logging in To APX15............................................................................................................................. 31

Configure True View Wi-fi ................................................................................................................. 31

Log in to APX-15 ............................................................................................................................... 33

Download T04 Files....................................................................................................................... 33

Measuring GNSS Lever Arm Offsets ..................................................................................................... 34

Z Offset............................................................................................................................................. 35