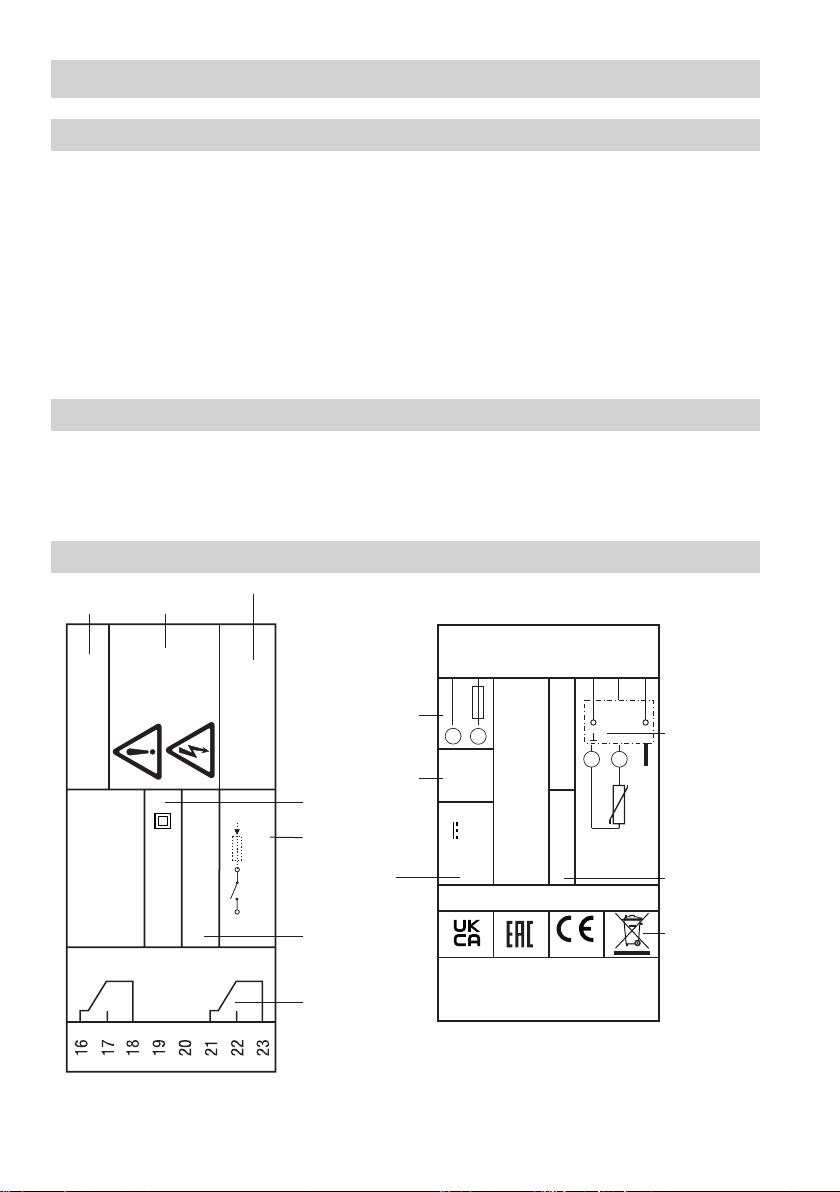

4LRS 1-50 - Installation & Operating Manual - 819223-03

Important notes

Usage for the intended purpose

The LRS 1-50 conductivity switch is used in combination with the LRG 1.-.. conductivity electrodes

as a limit switch, e.g. in steam boilers and hot water installations and in condensate and feedwater

tanks. The conductivity switch indicates when a MIN and MAX conductivity has been reached.

The LRS 1-50 conductivity switch can be combined in a circuit with the LRG 12-1, LRG 16-4, LRG 16-9,

LRG 17-1 and LRG 19-1 conductivity electrodes.

Function

In combination with the LRG 1.-.. conductivity electrode, the LRS 1-50 conductivity switch measures

the electrical conductivity of conductive fluids. LRG 12-2, LRG 16-4, LRG 17-1, LRG 19-1 conductivity

electrodes can be connected, or the LRG 16-9 model with integrated resistance thermometer for meas-

uring the fluid temperature. A separate Pt100 resistance thermometer may also be used to measure the

temperature.

When the LRG 1.-.. conductivity electrode is connected, a reference measurement is taken and the

conductivity reading is then adapted to the installation conditions by adjusting correction factor CF.

If a resistance thermometer is connected, the water temperature is measured as well as the conductivi-

ty. This enables the change in conductivity that occurs as the temperature rises to be compensated and

referred to the normalised reference temperature of 25 °C.

For this purpose, the water temperature is measured in the conductivity switch and the reading is auto-

matically compensated as a function of the adjusted temperature coefficient tC (%/°C). If the tempera-

ture changes, thanks to linear temperature compensation the reading is referenced to 25 °C across the

entire measurement range, and shown as an actual value on the 7-segment LED display.

The MIN/MAX limits can be adjusted as long as they remain within the measuring range.

If the MIN or MAX limit is reached, the MIN or MAX output contact switches and the MIN or MAX LED

lights up. It switches back when the conductivity is above or below the set hysteresis.

Faults or malfunctions in the conductivity electrode, the electrical connection or the settings are indicat-

ed on the 7-segment LED display. In the event of a malfunction, the MIN and MAX alarm is triggered.

If faults occur only in the LRS 1-50 conductivity switch, the MIN and MAX alarm is triggered and the

system is restarted.

Parameters can be changed or the MIN/MAX alarm simulated by operating the rotary knob.

Electrical conductivity is measured in µS/cm. In some countries, ppm (parts per million) is used instead.

Conversion 1 µS/cm = 0.5 ppm. The conductivity switch can be set as appropriate.