4

Important notes

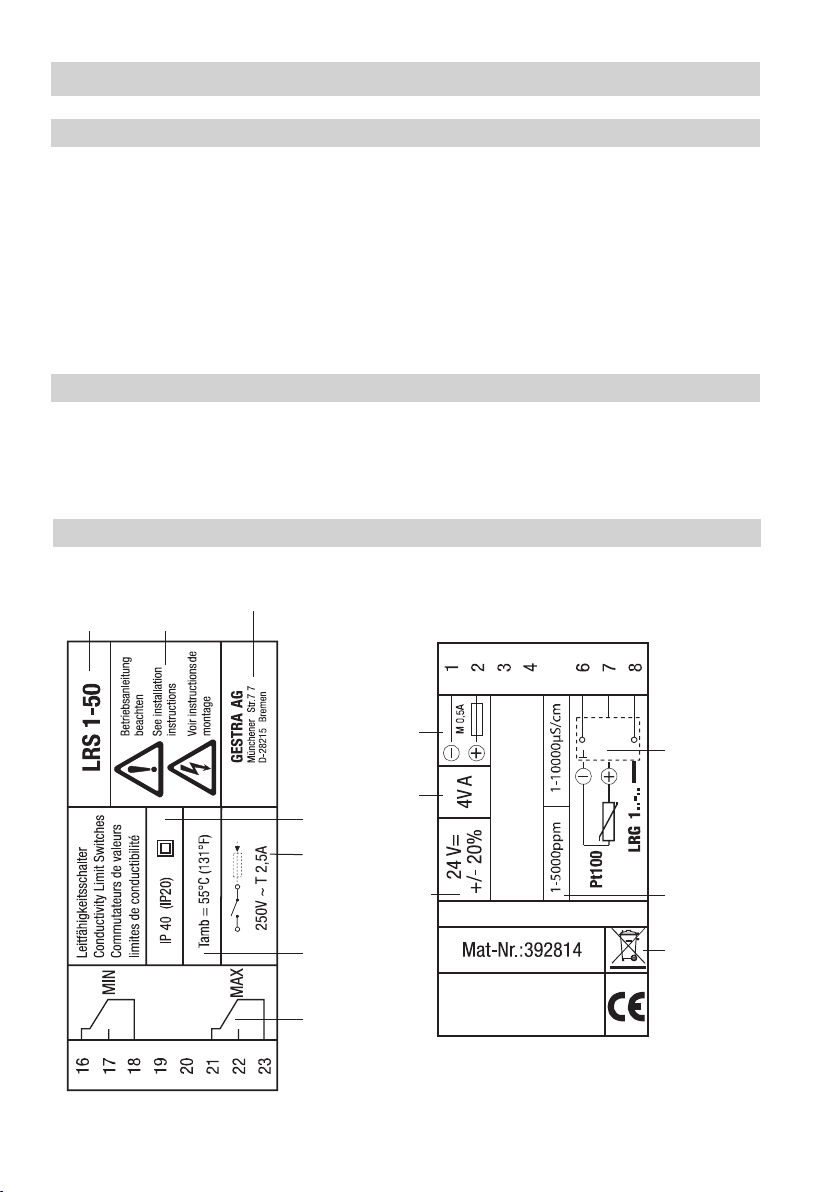

Usage for the intended purpose

The conductivity switch LRS 1-50 in conjunction with conductivity electrodes LRG 1.-.. is used as limit

switch, for instance in steam boilers, (pressurized) hot-water installations and condensate and feedwa-

ter tanks. The conductivity switch detects and indicates a MIN and a MAX conductivity limit.

The conductivity switch LRS 1-50 is designed for use in combination with the following conductivity

electrodes: LRG 12-1, LRG 16-4, LRG 16-9, LRG 17-1 and LRG 19-1.

The conductivity switch LRS 1-50 in conjunction with the conductivity electrode LRG 1.-.. measures

the electrical conductivity in conductive liquids. The conductivity electrodes LRG 12-2, LRG 16-4, LRG

17-1, LRG 19-1 or the LRG 16-9 with integrated resistance thermometer for detecting the fluid tem-

perature can be used with the conductivity switch. To measure the temperature you can also use a

separate resistance thermometer Pt 100.

When connecting the conductivity electrode LRG 1.-.. a reference measurement is taken and by set-

ting the correction factor CF accordingly the conductivity readings are adapted to the specific condi-

tions of the installation

If a resistance thermometer is used, not only the electrical conductivity but also the water temperature

will be measured. The conductivity readings can then be referenced to the standard reference tem-

perature of 25 °C and the conductivity value will be automatically compensated for temperature.

For this purpose the water temperature is constantly measured by the conductivity switch and the con-

ductivity reading is automatically compensated as a function of the adjusted temperature coefficient tC

(%/°C). Even if the temperature changes, thanks to the adjusted linear temperature compensation, the

measured value is referenced to 25 °C over the whole measuring range and indicated on the 7-seg-

ment LED display.

The MAX /MIN limits can be variably adjusted within the measuring range.

When the MIN or MAX limit is reached, the MIN or MAX output contact is switched over and MIN

or MAX LED is illuminated. The equipment will be reset once the value passes outside the preset

hysteresis.

Any faults or malfunctions in the conductivity electrode, the electrical connection or the settings will

be indicated by the 7-segment LED display. In the event of a malfunction a MIN and MAX alarm will be

triggered.

If an error occurs in the conductivity switch LRS 1-50, MIN and MAX alarms are raised and the system

is restarted.

Parameter settings can be changed or a MIN/MAX alarm be simulated by operating the rotary button.

The electrical conductivity is measured in µS/cm. In some countries ppm (parts per million) is used

instead. Conversion: 1µS/cm = 0.5 ppm. The conductivity switch can be adjusted accordingly.

Function