5

REQUIREMENTS TO THE SOURCE WATER

ATTENTION! The reverse osmosis system performance directly depends on a pressure in a

water conduit. If a pressure in your water conduit is less than 3atm., that it is necessary to

complement the reverse osmosis system with the booster pump.

The water pressure at the inlet of the system with a pump, atm. 2-8

The water pressure at the inlet of the system without a pump,

atm. 3-8

pH 3-11

Water temperature, °С +4...+40

Mineralization, mg/l no more than 1,500

Summary concentration of chlorides, mg/l no more than 1,200

Turbidity, mg/l no more than 1

Hardness, mg-equ/l no more than 7

Iron (Fe2+), mg/l no more than 0.3

Iron (Fe3+), mg/l no more than 0.3

Manganese (Mn), mg/l no more than 0.1

Nitrates, mg/l no more than 45

Permanganate oxygen consumed, mg О2/l no more than 10

Total microbial number, CFU/ml no more than 1,000

Coli-index 1

Higher values of indicators require the additional preliminary purication.

TECHNICAL CHARACTERISTICS

ATTENTION! If characteristics of the source water do not comply with the specied

requirements, that the operating life of the membrane and replaceable ltering modules can

be smaller than the operating life stated in this manual.

The storage tank volume (water volume in the storage tank is up to 70%* of its

volume), l 8; 12; 16

Excessive air pressure in the storage tank, atm. 0.4-0.5

Performance (depends on the water pressure and temperature, see appendix 1), l/day up to 200

Temperature of the puried water, °С +4...+40

Dimensions (without the storage tank), mm 470*380*420

* at a pressure in the water main of 5 atm.

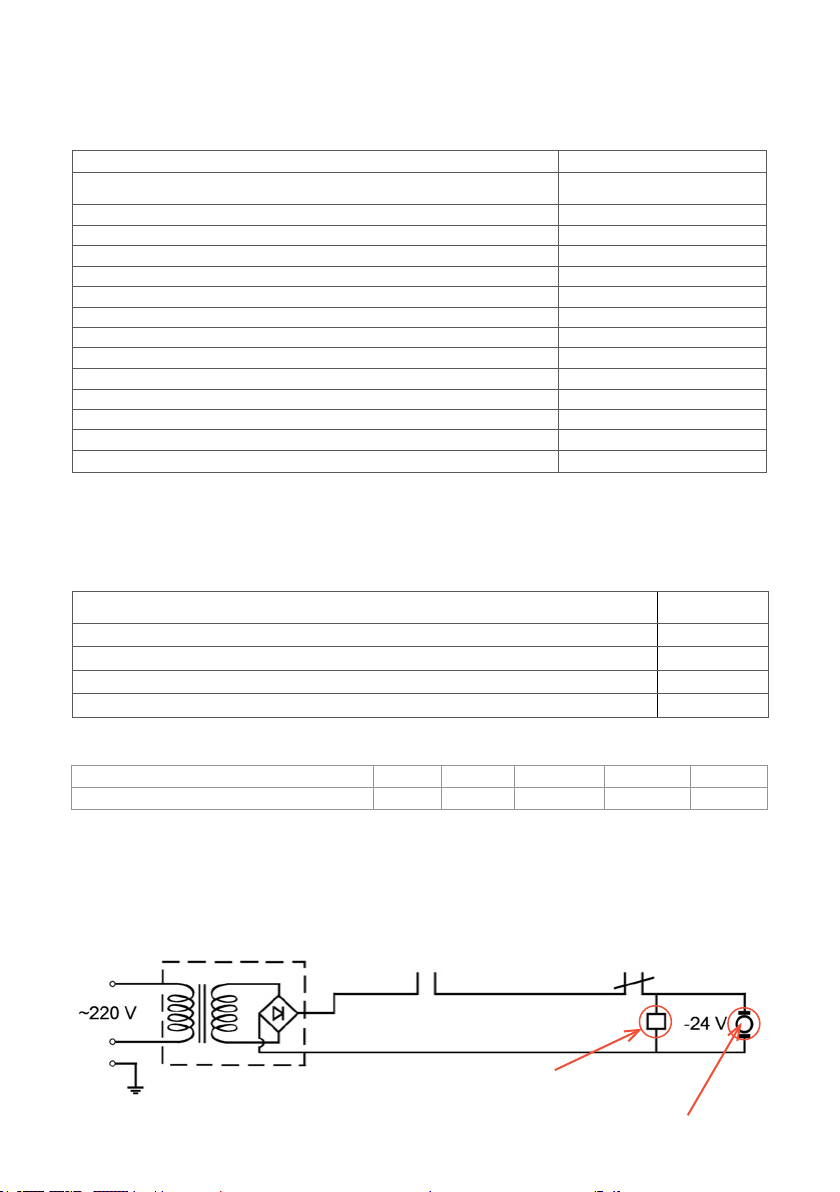

ADJUSTMENT TEMPERATURE COEFFICIENT*

TEMPERATURE 5 10 20 30 40

ADJUSTMENT COEFFICIENT 2,16 1,702 1,205 0,974 0,771

The membrane actual performance = the membrane performance stated in the table of technical

characteristics/the adjustment coefcient

* According to the data of the manufacturer of membranes Vontron Membrane Technology Co., Ltd.

Low pressure

controller

Power supply unit

Solenoid valve

Pump electric motor

High pressure

controller

ELECTRICAL SCHEME OF THE REVERSE OSMOSIS SYSTEM FOR MODELS

WITH THE PUMP