6ENGLISH

Loud noise when

adjusting bed height rusted moving parts, not lubricated

enough Add appropriate amount of

lubricating oil to the connecting

places of moving parts

Electric bed functions

failure Hand controller malfunction Replace the hand controller

The bed is not working The power plug is not inserted,

connect it to the power grid Plug in, power on

5. BED MAINTENANCE

1. In order to use the bed safely, it is necessary to conduct regular safety inspecons

on the bed, it’s recommended to conduct a comprehensive inspecon every six mon-

ths to ensure the connecon parts are not loose and the liing funcon of the bed is

operang normally.

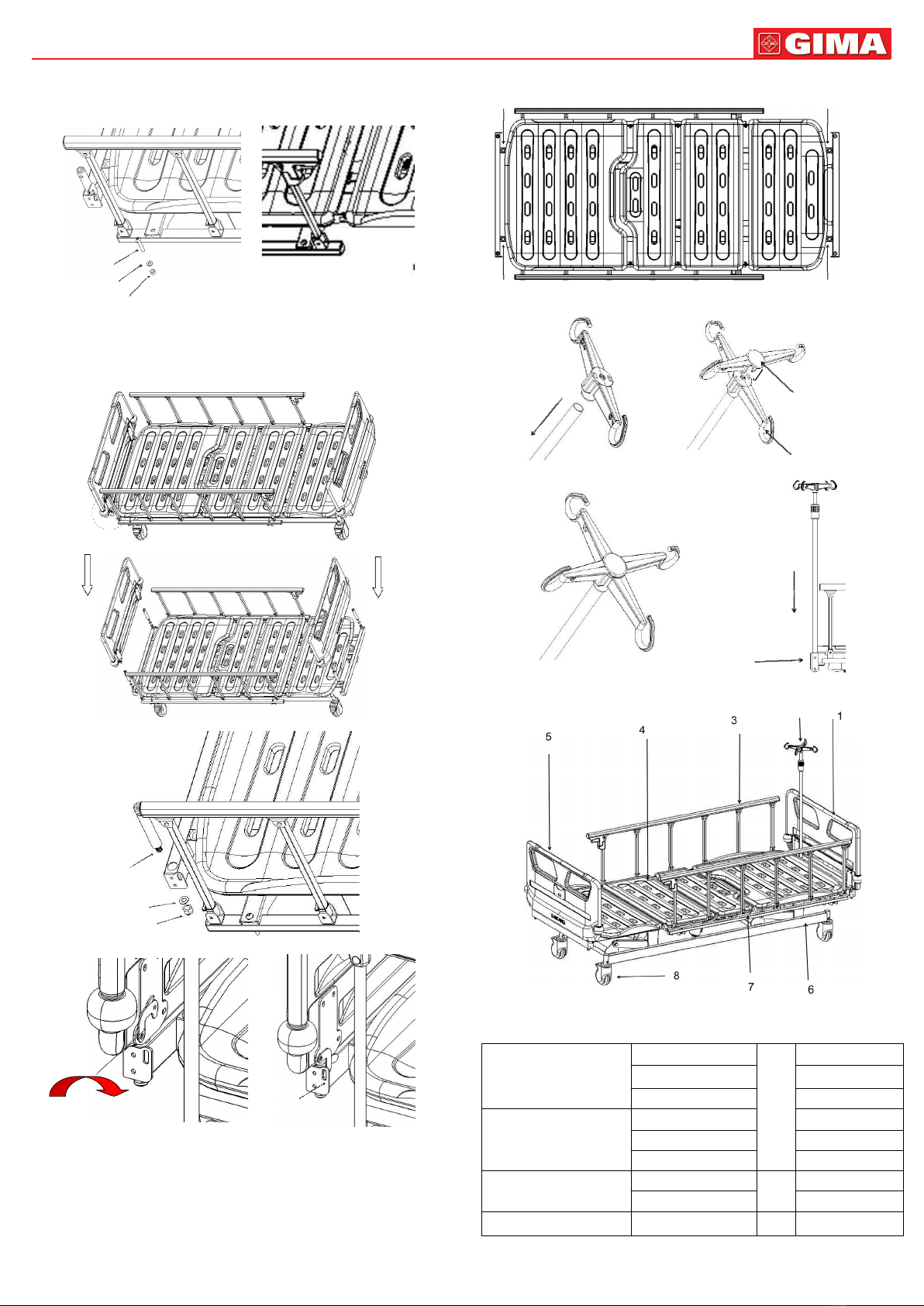

2. The connecon of the frequently moving parts of the bed needs to be lubricated

with an appropriate amount of oil during daily inspecon; is serious wear is found,

it should be replaced immediately to ensure safety. The moving part in gure below:

12

Moving part

3. Avoid hing the bed and scratching the coang on the bed surface with sharp

objects.

4. Please prevent the bed and maress from absorbing water and moisture, which

may cause rust, abnormal noises and bacterial growth. If there was water spilled,

please wipe it o immediately.

5. When the bed ages and reaches its service life me, the metal part and the plasc

parts can be recycled.

6. BED CLEANING PRECAUTIONS

1. When cleaning, please wring the cloth soaked in neutral detergent diluted with

water, wipe it dry, then wring the cloth soaked in clean water, wipe o the residual

detergent ingredients, and nally wipe with a dry cloth.

2. Do not use volale items (thinners, propellants, gasoline, etc) that may cause che-

mical reacons and damage the bed.

3. When cleaning with a disinfectant, be sure to use it aer dilung it at the specied

concentraon. Depending on the composion of the disinfectant, it may corrode me-

tal parts, resin parts, etc, causing discoloraon, deformaon and other undesirable

consequences.

Therefore, the recommended content of the disinfectant is as follows:

0.05~0.2% ammonium chloride

0.05~0.2% chlorinated phenyl

0.05% dichlorobenzene biguanide ethane

0.05~0.2% sodium hypochlorite

Do not use a smoking sterilizer or autoclave, and do not use methyl phenol to clean

the head foot board, bed feet, etc, which may cause corrosion, discoloraon, dete-

rioraon.

Note: When cleaning the bed or changing the bedding, pay aenon to the corners,

edges and screw parts of the frame to prevent scratches.

7. MATTRESS MAINTENANCE

1. Avoid scratching the fabric with sharp-angled appliances or knives when using it,

cover it with sheets or cleaning pads, and clean it frequently to keep it clean and dry.

2. Regularly clean the maress cover with a vacuum cleaner, it can be washed direct-

ly with water or detergent.

3. Air the maress oen to keep your sleep fresh and comfortable, but be careful not

to expose the maress to the sun for too long.

4. If the fabric is accidentally stained, please refer to the corresponding recommen-

ded cleaning method in the instrucons. Do not use corrosive chemicals to clean

the fabric.

5. If you accidentally get chewing gum or other glue-like objects on the fabric, do

not wipe it forcibly. You can use am ice pack to allow it to harden and then peel it

o gently.

6. If the thread is found to be loose due to wear and tear, it cannot be broken by

hand, and it should be cut short with scissors.

* Your order may not have a maress included, please refer to the contract con-

guraon.

8. CASTERS INSPECTION AND MAINTENANCE

1. Check the casters regularly, avoid hing heavy objects or overloading, which will

cause damage to the casters.

2. The casters should be applied with lubricang grease regularly, the frequency of

appliance should be determined according to the specic actual use situaon. Under

normal condions, the grease should be applied every six month.

3. Aer cleaning the caster equipment, pay aenon to adding lubricang grease.

The selecon of lubricang grease should be based on the actual use environment,

special high low temperature environment, etc.

4. It’s forbidden to push the bed with force when the casters are braked, which will

cause damage to the braking system.

5. The wear of the re tread of the caster can be detected by visual inspecon. Some

accumulaons such as thread and spun yarn may wrap around the caster. Remove

the bolts and nuts of thecaster, clean up the debris, and check whether the bearing

of the caster is damaged. If the parts are not damaged, the caster can be reassem-

bled and used.

6. Decision whether to replace enre caster is according to the wear condion. Aer

the caster is replaced or reinstalled, make sure that the axle bolt and nut are con-

nected reliably, and use lock washers or lock nuts as much as possible.

7. For casters equipped with brakes, it is necessary to regularly check whether the

brakes work normally, and check the brakes every day or before each use. For a ho-

spital bed equipped with mulple brake casters, you can lock only one brake caster

at a me and try to push the bed to check whether the braking performance of each

caster is good. If the caster brake fails to funcon due to wear or damage to the ca-

ster, replace the caster immediately and retest the brake system.

8. If the mechanism of the brake system is damaged, and the brake needs to be re-

paired or replaced, please contact our aer- sales or an authorized dealer. Every me

the brakes arereplaced, the brake performance of the casters needs to be retested.

9. SIDE RAILS MAINTENANCE

1. Please check whether the side rails are installed correctly to prevent the lying

paent from shiing and rolling o.

2. Please always check the screws of the side rail and the side rail ngs, to prevent

loosening and falling o.

3. Please use the red part of the side rail handle correctly, do not use brute force to

pull hard, which will cause damage to the side rail.

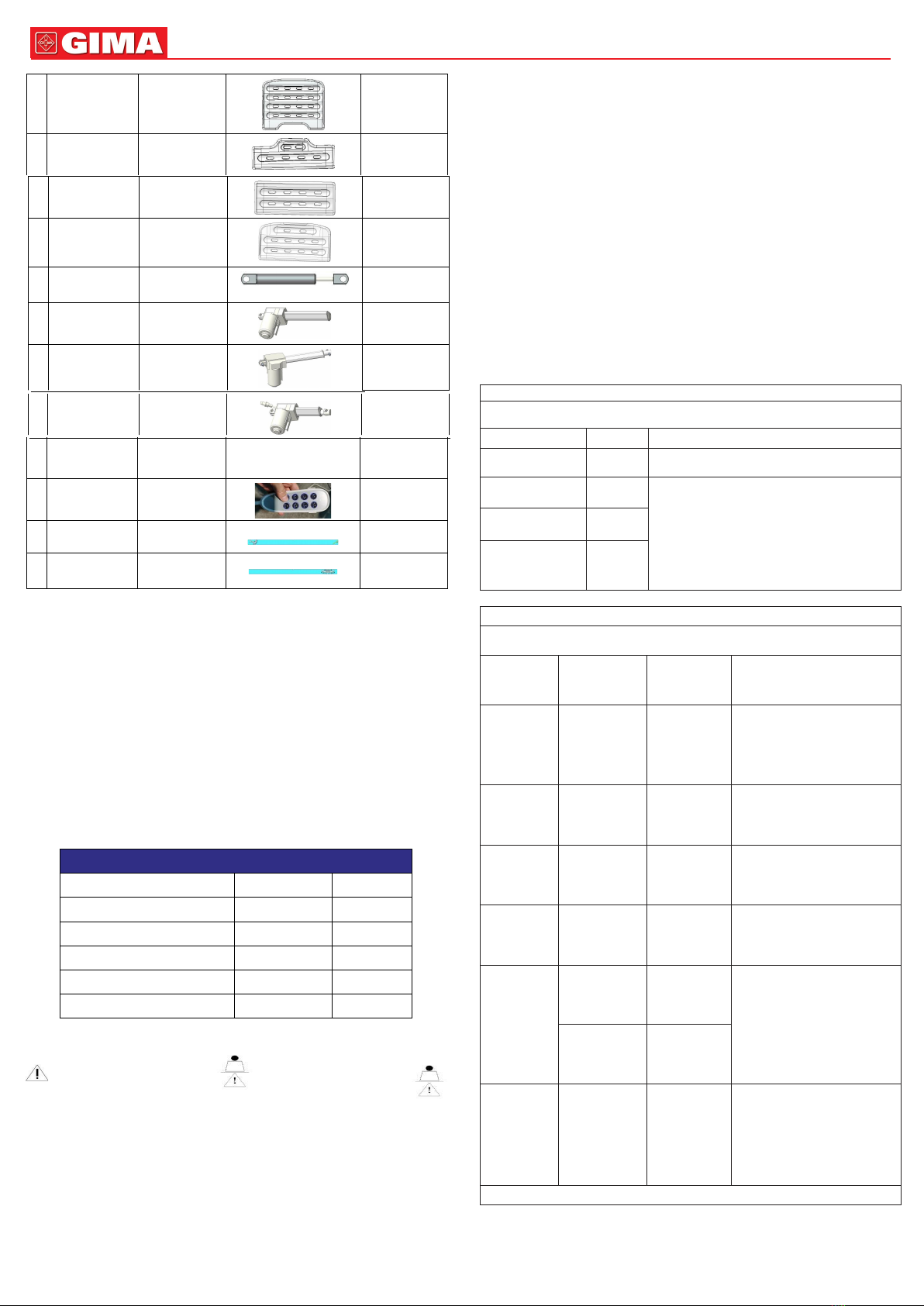

10. LIST OF WEARING AND SPARE PARTS

№Name Material code Picture Specication

1V21 head foot

board GPSL101TS648 990*460

2Aluminum alloy

side rail, left BKLLGH105943 Six sections /

QB/260*5/

φ10*1170

3Aluminum alloy

side rail, right BKLLGH105944 Six sections/QB

/260*5/φ10*1170

4Stainless Steel IV

pole with 4 plastic

hooks S0FJSY010003 Φ16-19/o-white

55”covered caster

with brake,slide bar

with bolt Φ23.6

LGPLU101TS122 M8(QB)

6 Drainage hook BYKBGKM02806 30-50 (plastic)

7Transparent

bedside card

holder(1 card) GPSL101TS184 /

R-type lock pin R-type lock pin

Lock pin Lock pin

4. TROUBLESHOOTING

Common issues Possible reason Troubleshooting

Diculty in moving

the bed 1. didn’t lift the brakes, locked

casters 2. casters are broken 1. lift the brakes, see 2.1

2. replace casters, see 1.2

Side rail easy to loosen side rail isn’t snapped into place Raise side rail up again, make

sure “click” sound