-2-

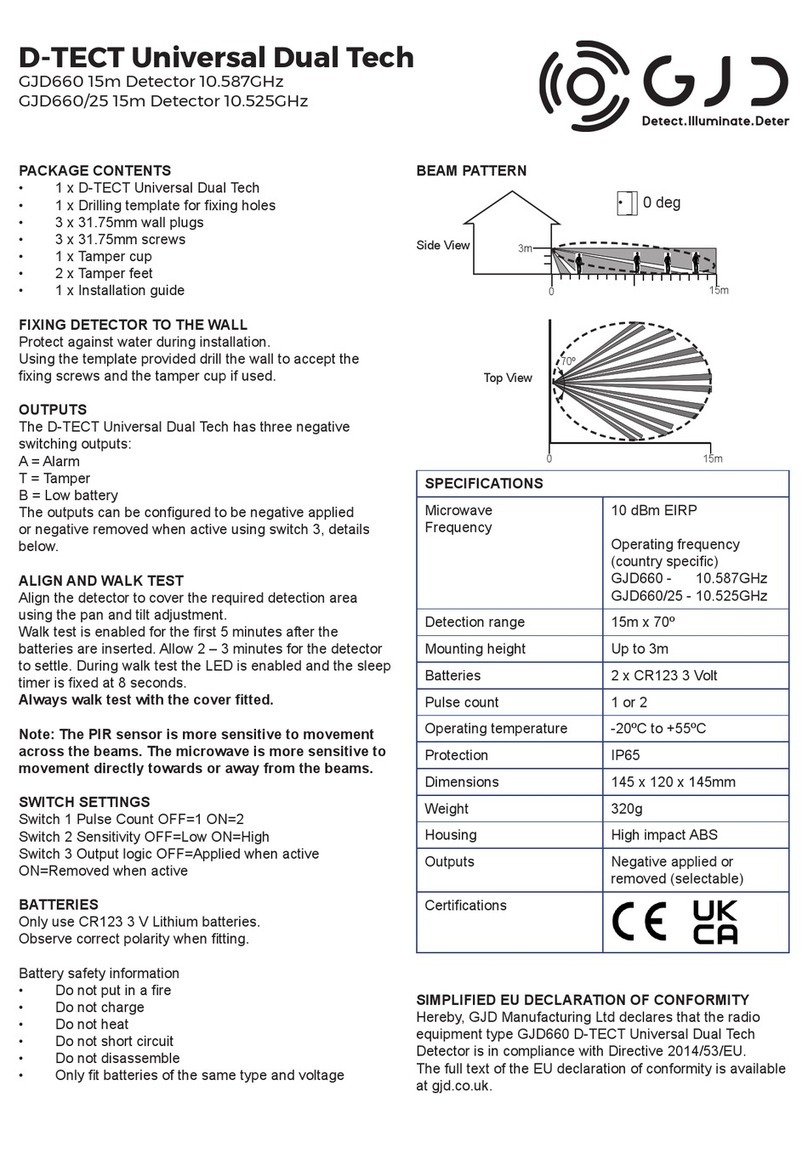

Programming

The user can individually program a number of congurable

settings, as illustrated in the programming chart below using the

program button and LED shown in Figure 4.

The factory default settings are set to suit the most popular

applications but can be changed to suit individual requirements,

either before installation or on-site. Once changes have been

made they are stored in a non-volatile memory.

The default factory settings for the D-Tect X MKIII detector are

as follows:

Range 50 metres (15 minute supervision)

Pulse Count 1

Lux 5

Timer (seconds) 5

To change factory default settings, proceed as follows:

1. Press the ‘Program Button’ the required number of times

to access the setting/mode that needs changing and a

red LED will illuminate (see following information and

programming chart)

Once - transfers code

Twice - sets detector range in metres

Three times - sets the pulse count

Four times - adjusts LUX level

Five times - sets alarm activation time in seconds

Six times - shows existing settings

Seven times - resets detector to factory settings

Eight times & hold down - starts RF continuity test

Nine times & hold down - generates new random

communication code

PROGRAMMING CHART

Setting 1 2 3 4 5 678

Press Twice -

Range Metres

(Supervision

time)

30

(15)

40

(15)

50

(15)*

30

(2)

40

(2)

50

(2)

Press 3 times -

Pulse Count

1* 2

Press 4 times -

“S” Output LUX

level

25* 10 20 30 40 50 24

hr

Press 5 times -

Timer (seconds)

25* 10 20 30 40 50 60

* Default settings

To re-set the default settings remove the batteries, wait 10

seconds, press and hold the program button then re-t the

batteries, the LED will ash rapidly then release the program

button.

2. When the ‘Program Button’ has been pressed the required

number of times, wait 4 seconds until the red LED

indicator goes off.

3. After a short delay, the LED will then ash a number of

times to indicate the existing setting (eg in detector range

mode, 3 ashes will show that the existing range has been

programmed to 50 metres with a 15 minute supervision

timer)

4. To change the setting for that option – wait until the

LED stops ashing then press the ‘Program Button’ the

number of times needed to program in the new setting (eg

pressing the button twice in range mode will change the

setting to 40 metres with a 15 minute supervision timer).

The LED will blink twice to indicate that the new setting

has been saved.

Functions

Range settings are self explanatory but for reference, other

settings/modes are dened below:

Pulse Count (1, 2) – this is the number of times the unit has

to detect an intruder on both of its sensors before signalling an

activation. The range of the detector will decrease if there is little

difference in temperature between the moving object and the

background.

1 – will give a fast response

2 – gives better immunity with good response

LUX ‘S’ Output only – 7 settings from 2 to 50 lux – the 8th

setting is the 24 hour mode.

a) LUX – is a measurement of ambient light levels that must be

reached before the ‘S’output will become active when there is an

activation of the detector (2 is night and 50 is lighter).

b) 24 HOUR – the detector will operate the ‘S’ output day and

night, irrespective of light levels. All other outputs operate day

and night irrespective of the ‘S’output setting.

TIME ‘ALARM’ OUTPUT TIMER

This is the active time in seconds that the ‘alarm’ volt free output

will activate for after an activation of the detector.

Rf Continuity Test

It is always advisable to test the RF signal at the detector location

prior to installation.

To enter the RF continuity test mode – press the ‘Program Button’

on the D-Tect X MKIII 8 times.

On the 8th press – ‘hold’ down the ‘Program Button’ for 5

seconds until the LED goes off – the LED indicator will then ash

and transmit one signal per second to the receiver.

The corresponding Channel Indicator on the receiver module will

also ash once per second if a strong enough RF link has been

established.

This test mode will automatically cancel after ve minutes.

Alternatively, to cancel the RF continuity test immediately – press

and hold the ‘Program Button’ until the LED illuminates then

release the button.

Register one detector as described in ‘Code Learning’, then

conduct an RF continuity test as detailed above. As the signals

to the receiver are sent once per second, the optimum position of

both the D-Tect X MKIII detector and the receiver box can easily

and quickly be established.

Changing The Random Code

In the unlikely event of another radio signal interfering with

and affecting the correct operation of a single RF channel, the

D-TectX30 MKIII is able to generate an alternative random code.

To do this, press the Program Button on the D-Tect X MKIII nine

times. On the ninth press, ‘hold’ down the button for 5 seconds

until the LED goes out, then release the button.

Erase the existing code from the receiver by holding down the

Channel Button until the alarm LED ashes, then repeat steps

3 to 6 of the CODE LEARNING procedure to program in the new

code.