Introduction

About This Manual

Before operating, maintaining or servicing any

GlasCraft system, read and understand all of the

technical and safety literature provided with GlasCraft

products. If you do not have the proper or related

manuals and safety literature for your GlasCraft sys-

tem, contact your GlasCraft distributor or GlasCraft,

Inc.

In this GlasCraft technical and safety publication, the

following advisories will be provided where

appropriate:

NOTE

Is information about the procedure in progress.

CAUTION

Is imperative information about equipment

protection.

WARNING

Is imperative information about personal safety.

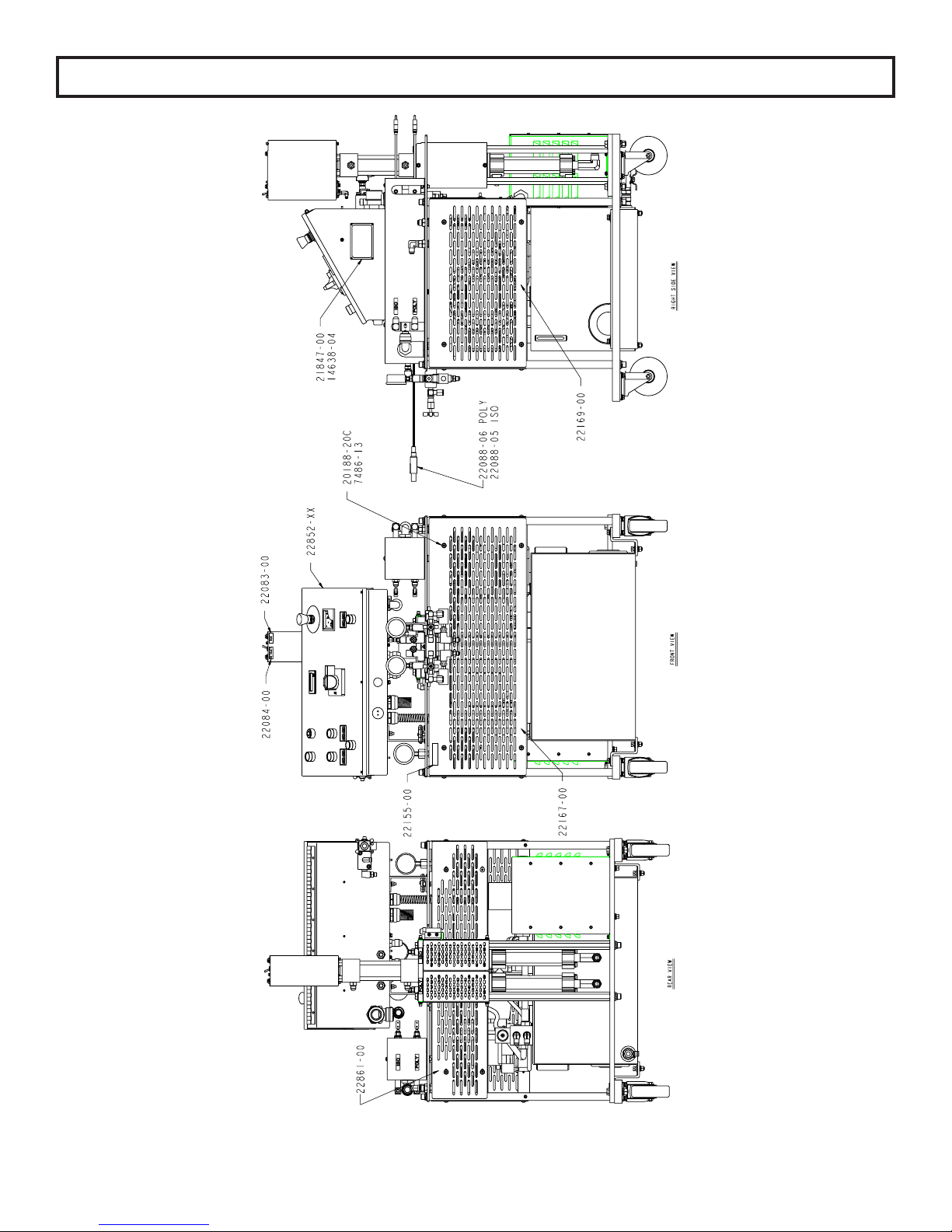

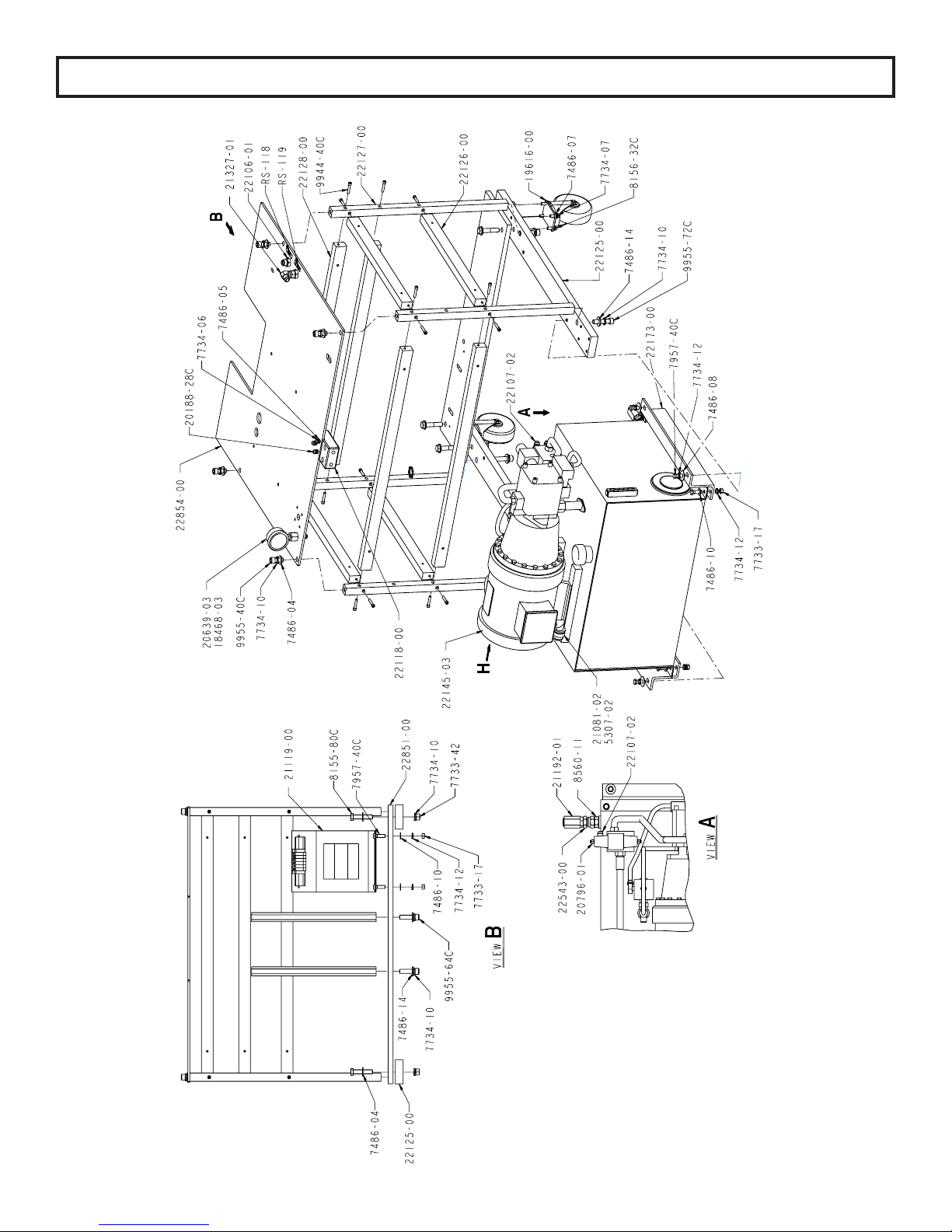

The information in this document is intended only to

indicate the components and their normal working

relationship typical use. Each assembly should be

directed by a GlasCraft distributor or

made from the GlasCraft assembly instructions pro-

vided.

This manual provides information for the assembly,

operation, maintenance and service of this GlasCraft

product as used in a typical configuration. While it

lists standard specifications and procedures, some

deviations may be found.

In order to provide our users with the most up-to-date

technology possible, we are constantly seeking to im-

prove products. If technological change occurs after

a product is on the market, we will implement that

technology in future production and, if practical, make

it available to current users as a retrofit, up-date or

supplement. If you find some discrepancy between

your unit and the available documentation, contact

your GlasCraft distributor to resolve the difference.

GlasCraft, Inc. reserves the right to change or modify

this product as it deems necessary.

Careful study and continued use of this manual will

provide a better understanding of the equipment and

process, resulting in more efficient operation, longer

trouble-free service and faster, easier troubleshoot-

ing.

1