9

Section 1 - Installation: Equipment Assembly

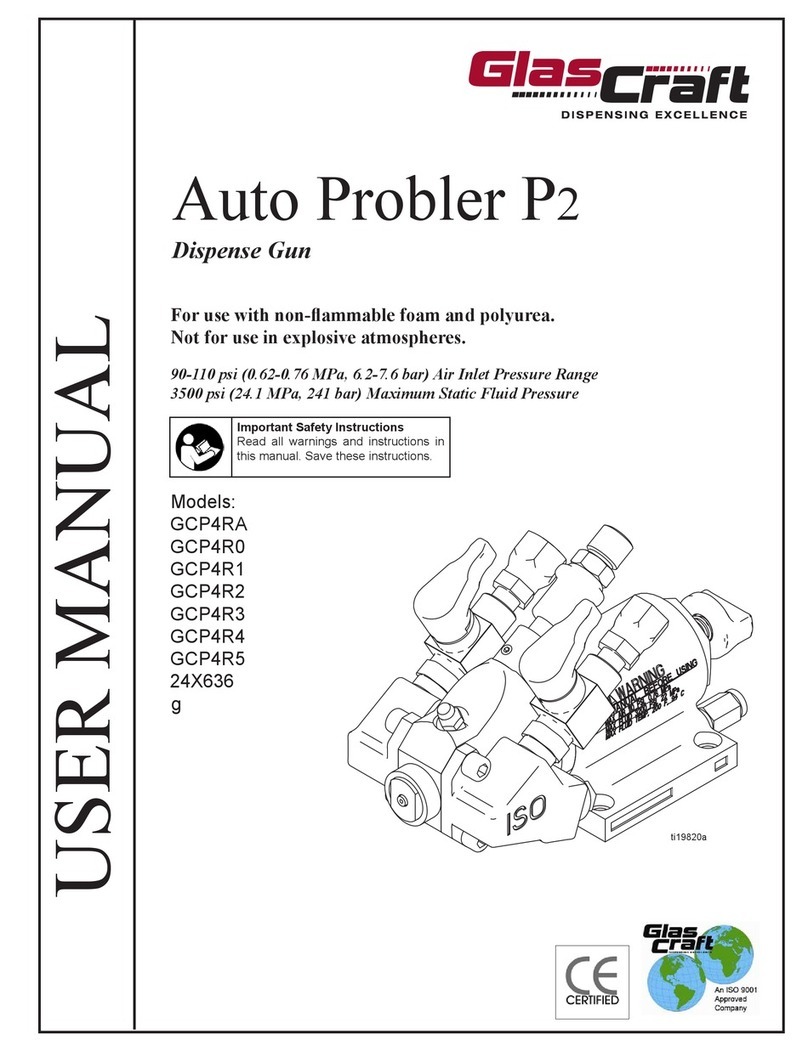

How The Gun Works

The Probler Gun is used to spray or pour two-

component, low viscosity polyurethane foam materials

at outputs up to 60 pounds per minute. The gun

features an air-assited full-nger trigger and a

patented solvent-free automatic air-purge cleaning

system.

The trigger actuates a small valve in the gun handle

that controls the ow of air into the piston assembly.

When the trigger is pulled, air ows through the valve to

the front of the piston. Air pressure forces the piston to-

wards the rear of the gun, simultaneously closing off

the purge air and moving the mixing chamber to a

position where the mixing chamber orices are aligned

with the orices in both the side block seal and

check valve assemblies.

The proper alignment of the orices is determined by

the setting of the Set Screw, p/n GC0143, located

at the rear of the piston assembly. This set screw

determines the length of travel of the air piston and

has been preset at the factory and should not require

adjustment. (SEE MAINTENANCE SECTION)

The two uids (isocyanate and polyol) then ow through

the material shut-off valves, seal, and check valve

assemblies and into the mixing chamber. The two

uids impinge against one another and exit the mixing

chamber in a swirling, conical spray pattern.

When the trigger is released, the mixing chamber

returns to its original position and purge air ows into

the mixing chamber housing. The front

tip o-ring, keeps air purge inside the gun

head, forcing all of the air through the

orices in the mixing chamber, for a complete, total and

constant purge.

This purge air continues to ow through the mixing

chamber until the air switch, is pulled up to shut-off all

air to the gun; or until the trigger is pulled again.

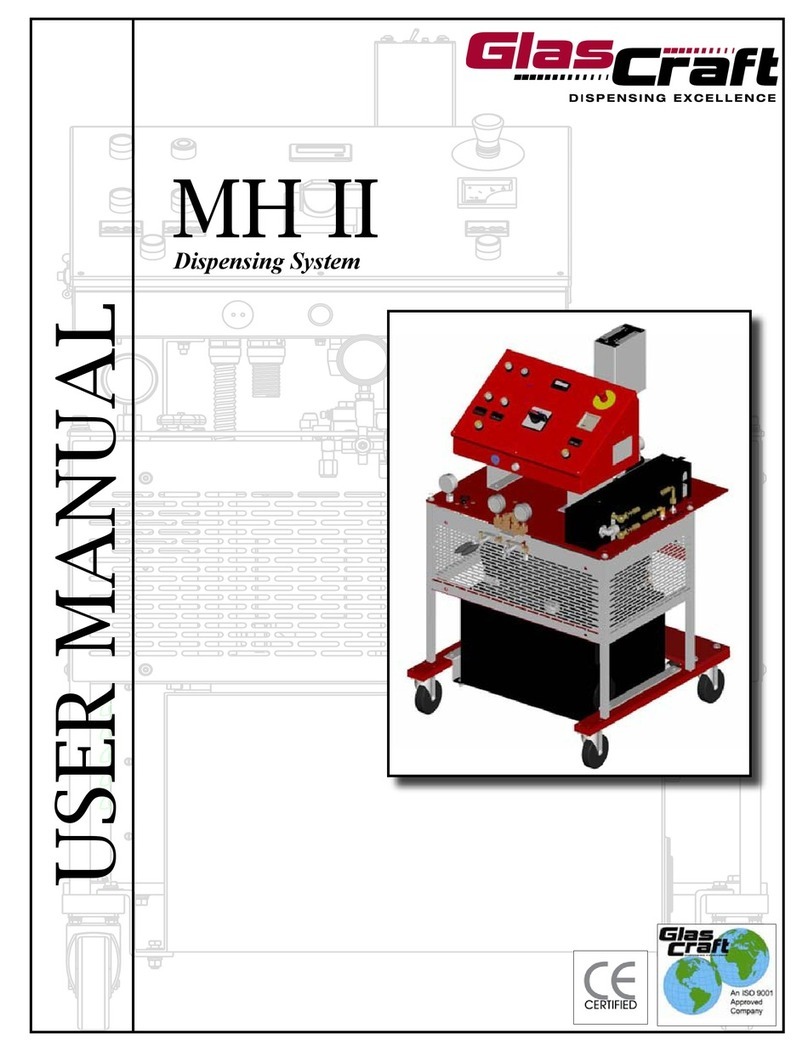

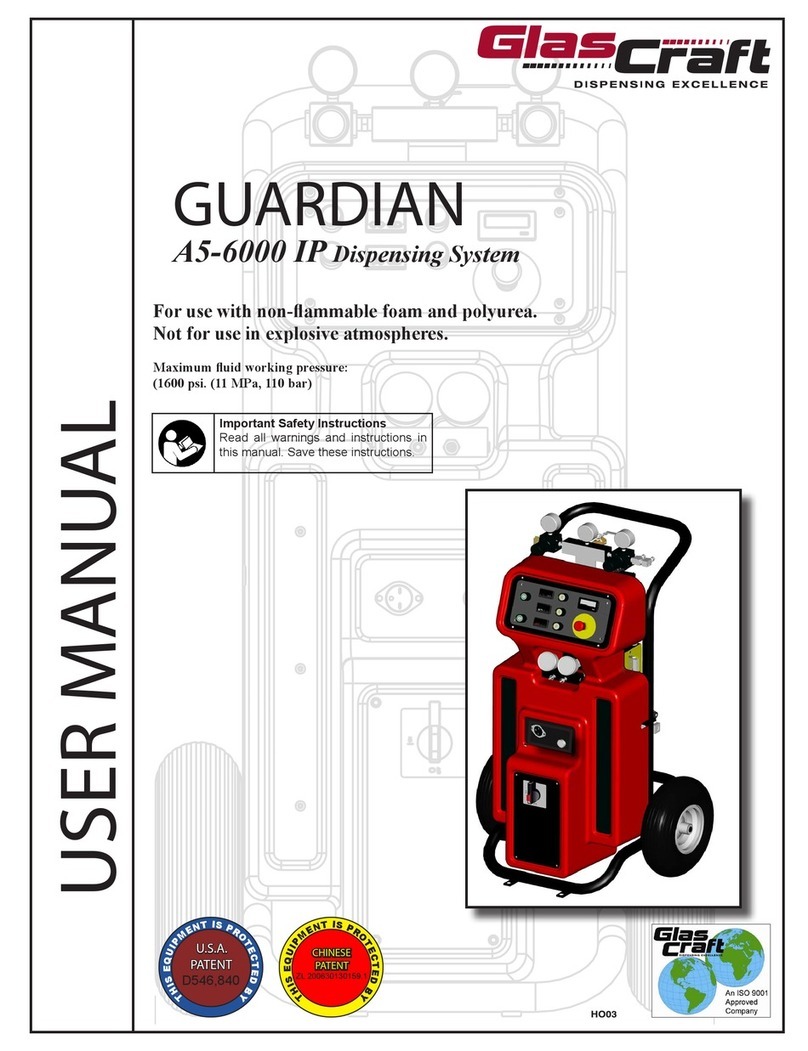

GlasCraft Equipment

Air Hose is ¼ in. NPS

JIC and SAE Fittings DO NOT require the use of PTFE

tape.

Once the ttings are attached and tight, refer to sys-

tem manuals for start-up instructions.

*Fitting GC2394 is an unattached part that may need to

be connected to the air hose rst, then connected to the

gun, depending on air hose tting.

ISO

*AIR

POLY