Analogue Addressable Fire Detector w/ Smart Addressing

TECHNICAL SPECIFICATIONS

ORDER CODE DESCRIPTION

GLOBAL FIRE EQUIPMENT S.A.

Sítio dos Barrabés, Armazém Nave Y, Caixa Postal 908-Z, 8150-016 São Brás de Alportel - PORTUGAL

Loop Powered - 17 V to 30 V DC

450 uA max.

4 mA - Alarm LED Iluminated

According to EN54-5 or/and EN54-7, EN54-17

0.5-2.5 mm²

20 seconds max.

White / ABS / 95% RH Non-Condensing

0°C to 50°C / -10°C to 85°C

100 mm (D) x 50 mm (H) inc. base / 144 g inc. base

SUPPLY VOLTAGE

CURRENT - QUIESCENT / SURGE

CURRENT - DEVICE IN ALARM

SENSITIVITY

CABLE SIZE

RESET/START-UP TIMES

COLOUR / CASE MATERIAL / MAX. HUMIDITY

NORMAL / TRANSIENT OPER. TEMPERATURE

DIMENSIONS / WEIGHT

ZEOS-AS-S

ZEOS-AS-H

ZEOS-AS-SH

ZEOS-AS-SI

ZEOS-AS-HI

ZEOS-AS-SHI

| CERTIFICATE | ANALOGUE ADDRESSABLE PHOTOELECTRIC SMOKE DETECTOR WITH SMART ADDRESSING

ANALOGUE ADDR. TEMPERATURE/HEAT DETECTOR WITH SMART ADDRESSING

ANALOGUE ADDR. COMBINED SMOKE & HEAT DETECTOR WITH SMART ADDR.

ANALOGUE ADDR. PHOTOELECTRIC SMOKE DETECTOR W/ ISOLATOR & SMART ADDR.

ANALOGUE ADDR. TEMPERATURE/HEAT DETECTOR W/ ISOLATOR & SMART ADDR.

ANALOGUE ADDR. COMBINED SMOKE & HEAT DETECTOR W/ ISOLATOR & SMART ADDR.

1328-CPR-0526

1328-CPR-0527

1328-CPR-0525

1328-CPR-0609

1328-CPR-0608

1328-CPR-0524

INSTALLATION

MECHANICAL SPECIFICATION

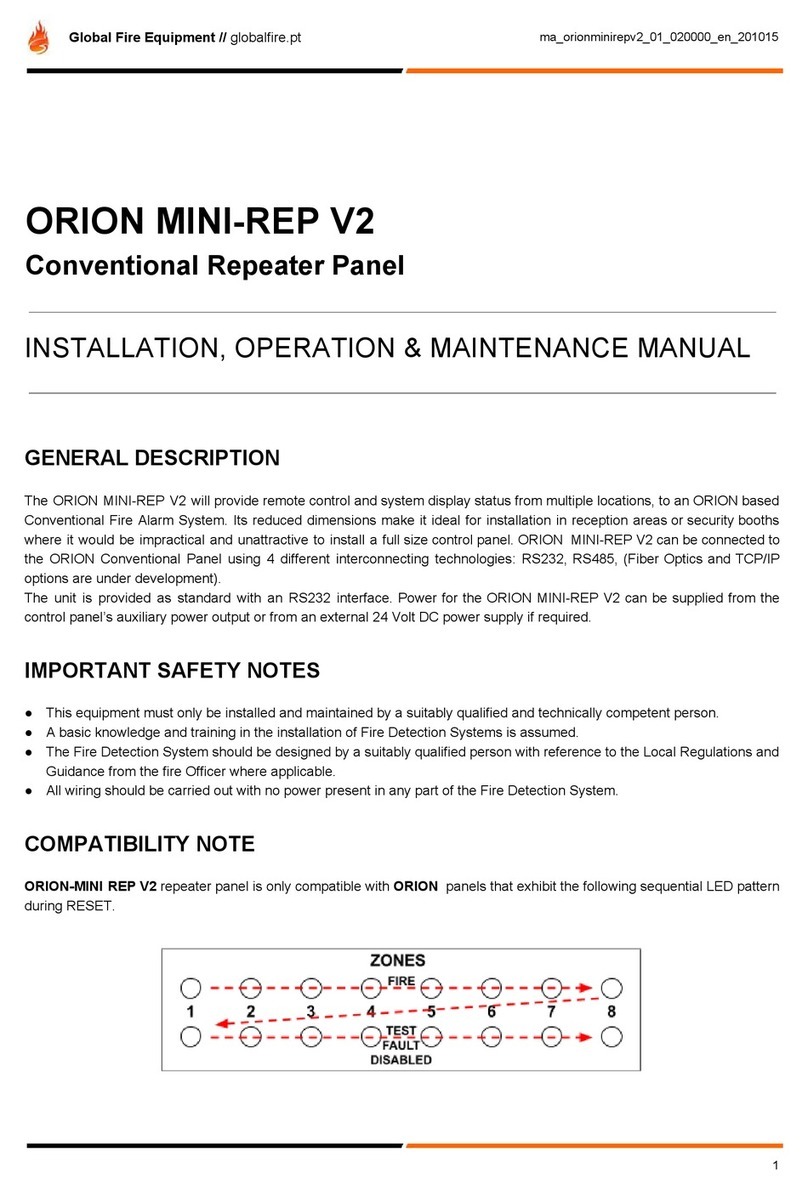

INSTALLINGTHEBASE

To ensure proper fit of the detector head tothe base, all wires should be properly dressed at installation by positioning all wires flat against

terminals and fastening the wires away from connector terminals. The detector base can be mounteddirectlyonto most standard electrical

junctionboxes.

INSTALLINGTHEHEAD

Align detector components using provided alignment marks on both the head and base. Align detector mark and short alignment mark on

base.Fitthedetector headontothebaseandtwistclockwisetosecure it.Afterall detectorsareinstalled,applypowertothe control unitand

activatethedetectionloop.Testthedetectorsasdescribedbelow.

TESTING

All remotesignalling systems,releasingdevicesand extinguishingsystemsshouldbedisconnectedduringthetestperiodand reconnectedat

theconclusionoftesting.

SMOKE:Allowsmokefromacottonwickortestsmokeaerosoltoenterthedetector’ssmokechamberforatleast10seconds.Whensufficient

smokehasentered,the detectorwillsignalan alarm.This will beindicatedby theilluminationofthe2Red LEDs provided. Makesuretoclear

smokeoutofthechamberbeforeresettinginordertokeepthedetectoratitscurrentsensitivitysetting.

HEAT: Thedetector tobetested shouldbe subject toa flow ofwarmair ata temperature ofbetween 65°C and 80°C. This requirement can be

metbysomedomestichairdryers.Switchonthewarmairflowandcheckthatthetemperatureiscorrectandstable.Fromadistanceofseveral

cms,directtheairflowattheguardprotectingthethermistor.Thedetectorshouldalarmwithin60seconds.Uponalarmimmediatelyremove

the heat source and check that the Red LEDs of the detector are illuminated. If a detector fails to activate within 60 seconds, confirm

connections and programming. If necessary replace unit. Note: After testing, check that the system is returned to normal operation. Notify

theappropriateauthoritiesthatthetestingprocedurehasbeencompletedandthesystemisactiveagain.

MAINTENANCE

The recommended minimum requirement for detector maintenance consists ofannual cleaning of dust from the detector head using a low

powervacuumcleaner. >>DONOTATTEMPTTODISASSEMBLETHEDETECTOR

Detector Head

Detector Base

Alignment Marks

ZEOS-AS ma_zeosas_01_010001_en_180420

MADE IN PORTUGAL - EU