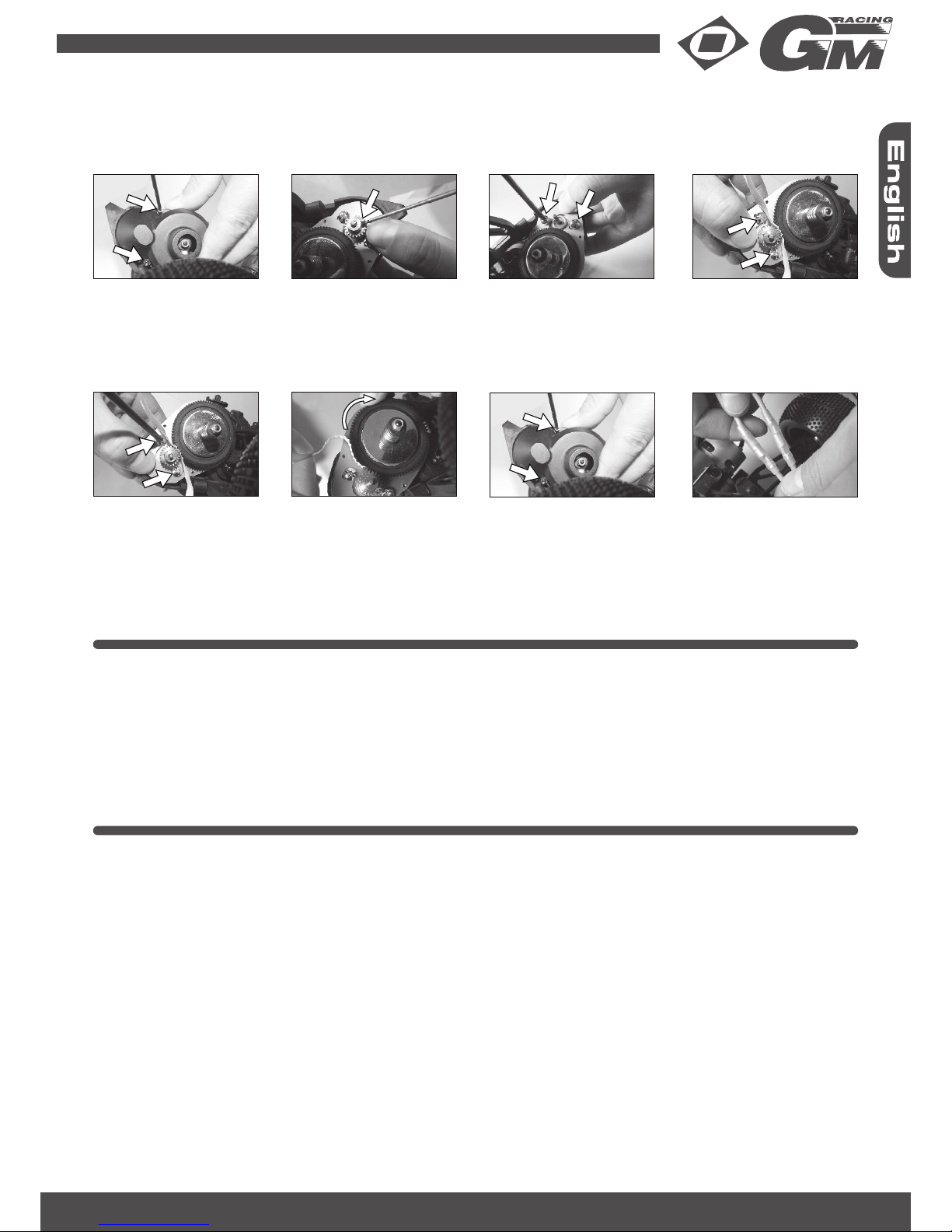

DAMPING

The four oil-filled shocks of this GM-Racing car have largest influence on its handling. Whenever you re-assemble these

shock absorbers again: Do it carefully! Assemble the absorbers always in pairs (in front and in the back). If one of the

front shocks should be somewhat softer or harder than the other one, the vehicle will steer along curves in one direction

different than in the other one. The same is valid for the rear shock absorbers. The absorption should be a bit harder in

the front than in the back to achieve a good-natured handling.

The ride height of the model is very important. It is to be adjusted in such a way that the arms of the front and rear

suspension go back to parallel to the ground, if you raise the model from the ground and then release it. This ensures

sufficient movement of the suspension in both directions (compression and releasing). If the car does not go back the

correct driving height, the feather/spring seals must be adjusted accordingly again.

It is normally best to begin with a softer shock oil and then try a harder oil. If the chassis jumps excessively strong on a

rough track, you should use a softer oil. If the tires take off with the same impacts from the surface of the track, the oil is

too thick. In this case a thinner oil is to be used, so the suspension reacts faster. Thus it is reached that the tire remains

as much as possible in contact with the surface of the course.

The shock absorbers can also affect the steering behavior of your car. This can be regulated by an appropriate soft or

hard adjustment of the front and rear suspension. The firmness is affected by feather/spring characteristic, thickness of

the oil and the inclination of the shock absorbers, as well as the combination of these three factors. With a soft rear end

the traction power (road grip) is improved, the steering more weakly. The handling of the vehicle can be foreseen here

more easily, because this is inclined in curves to understeer, i.e. pushes to the outside of the curve. If the rear suspensi-

on is too hard, the steering effect is stronger, but requires more skill by the driver, in order to avoid spinning the vehicle

around. During softer adjustment of the front suspension the guidance effect is strengthened and turned around, decre-

ased during harder attitude. Within the correct absorption range - chassis jump and hop the wheels - there is a narrow

fine tuning range, in which you can adjust the firmness of front and rear suspension. This is a tricky attitude, which must

be made by very small changes in the viscosity of the oil.

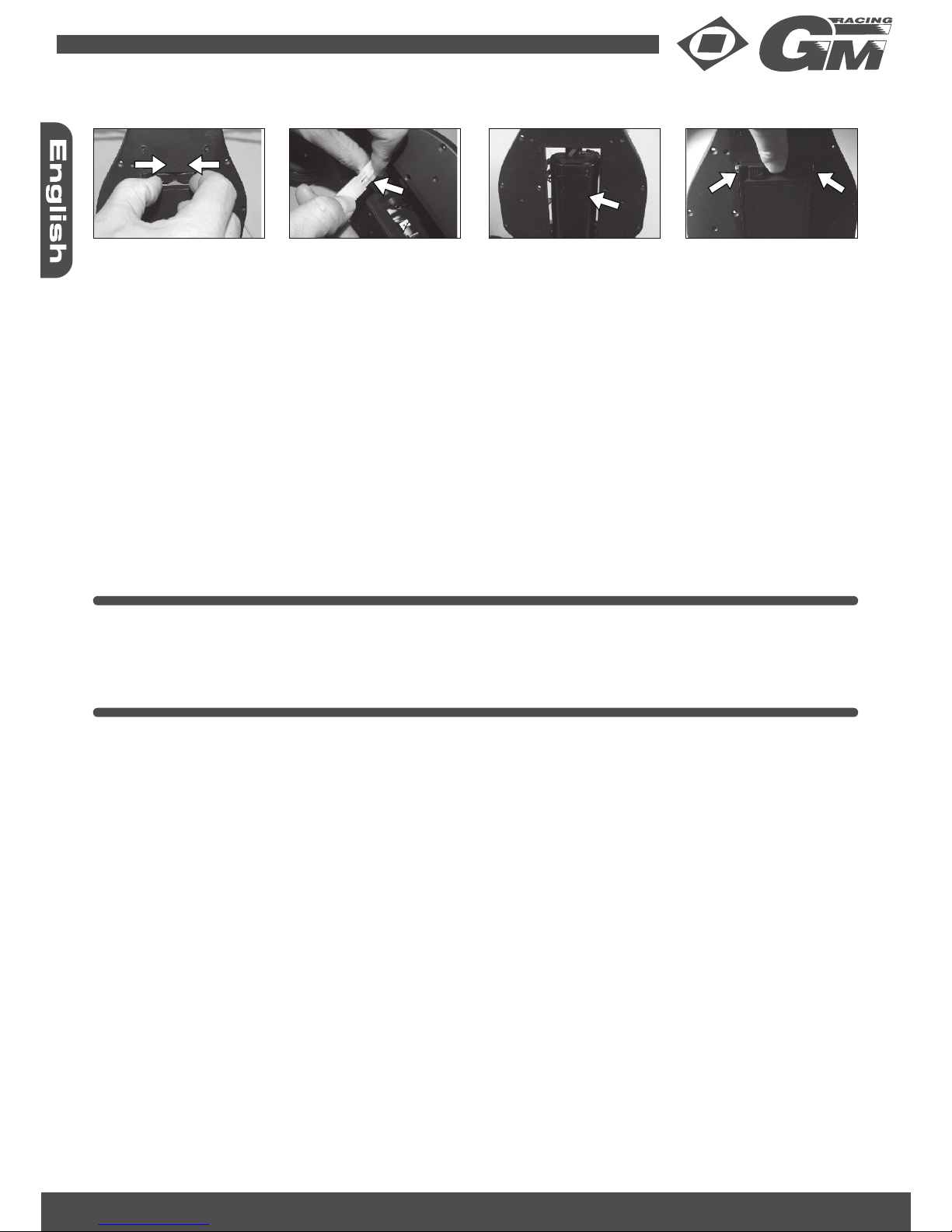

WEIGHT DISTRIBUTION

Always remember with adjusting the shock absorbers that the correct weight distribution is from great importance, so

that the GM-Racing car can show a perfect handling.

Preload the rear shock-absorbers on the right and on the left side with the same amount of tension directly and check

this for example with the help of a Tweak-board. The chassis tweak is adjusted if necessary by easily preload the springs

on the front axle.

With reducing the speed in the curve entrance the weight shifts on the two front wheels and/or - tire, with maximum

effect on the steering. On the opposite with accelerating the weight is shifted on the two rear tires, for maximum traction

power.

The more softly the suspension is, the more the weight transfer affects the handling of the car. For this reason it is

appropriate to make the suspension as fast responding as possible, but not so softly that the absorption becomes inef-

fective. Between these two extremes the „midway“ is the best, which you can determine on the own race track only by

the practical attempt.

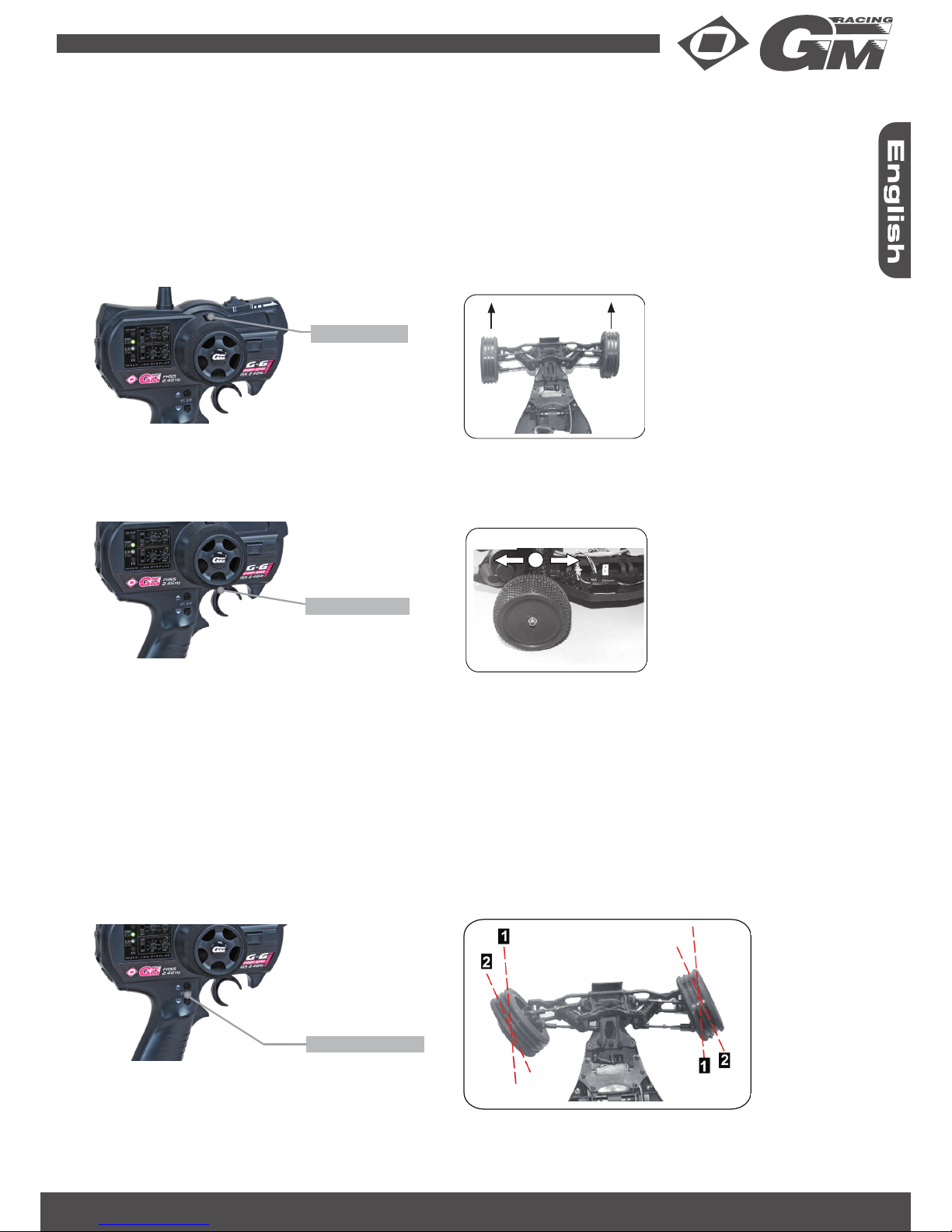

ADJUSTING THE WHEELS

First: make sure that the steering trim at the transmitter is in neutral position. Then adjust the servo-saver and the tie

rods in such a way that the wheels stand exactly in straight line adjustment. Thus it is guaranteed that the steering travel

is the same on both sides.

The toe-in is a skew of the wheels in driving direction (seen from above). This adjustment of the front wheels is important

for the handling of the vehicle. The travelling straight ahead of the model is improved by a small angle. The toe-in can

be adjusted by rotating of the right/left- threaded rods (tie rods) without disassembly of the ball joints. The tie rods are to

be adjusted in such a way that the toe-in amounts to approx. 0°-1°. It should be paid attention to the fact that the right

and left tie rod is equivalent long. At the beginning of driving with the car adjust all four wheels in such a way that they

stand with normal driving height perpendicularly to the ground. For examination hold a rectangle or an indication triangle

against the wheel, so that the wheels are adjusted exactly. When pressing on the suspension you will determine that the

wheels gets a little negative camber (spreading).

The reason for this is that you want to reduce the positive camber of the outside wheels when going into the curve. Thus

the bearing surface and the traction power of the outside tires and concomitantly the speed are increased when driving

through curves. The change of the negative camber (thus spreading) with the rear wheels is however the cause for a

reduction of the bearing surface of the tires of the rear wheels when pressing the suspension down by accelerating.

If your track has more straights than curves, it will possibly turn out that an additional decrease (positive) of the camber

is not necessary with driving along curves.

GM-Racing 90168.RTR Roadfighter Buggy 2WD 16