Installation and Operating Manual

Art. No. 13512-.../13513-...

Version 10.2012 Page 4

The installation of the GS Pro-Fi 3 is permitted:

•in single-pipe oil-fired installations with return feed (suction line)

•

above and below the oil tank top height

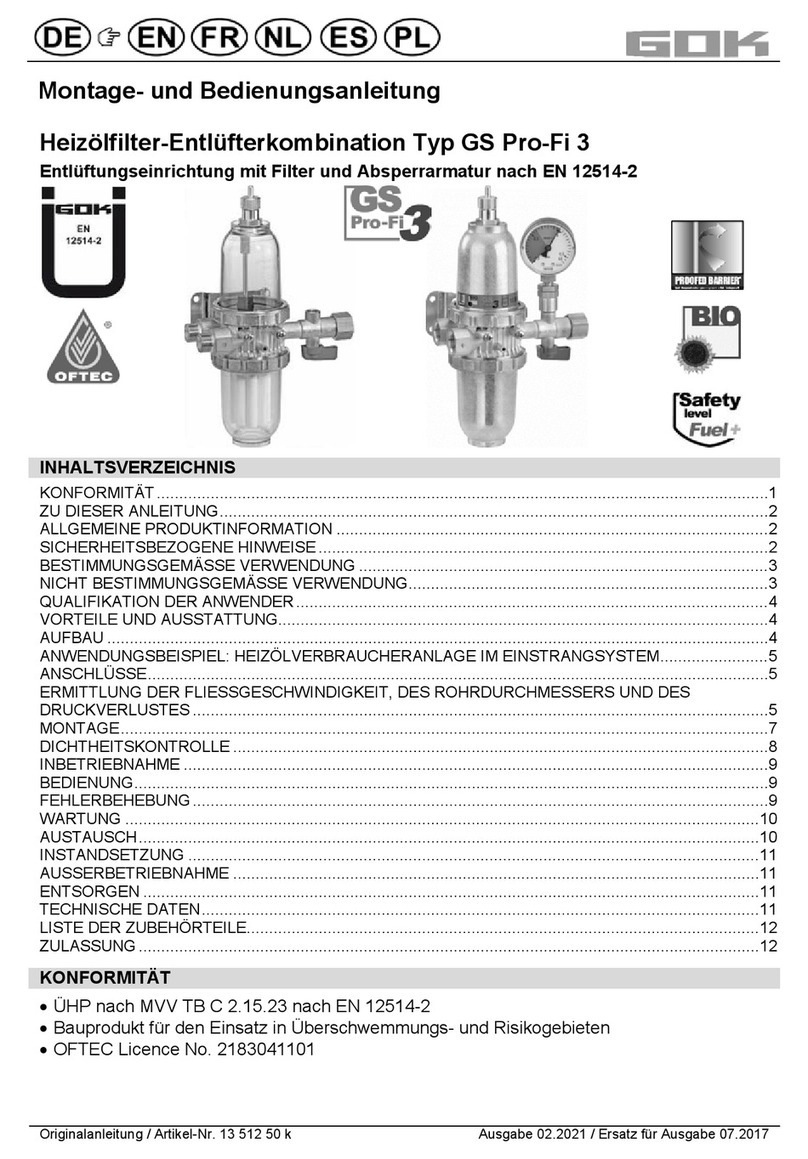

Installation position and fixing

The installation position is always vertical: filter cover ⑧with filter element ⑦below, deaerator cover ②on top.

The GS Pro-Fi 3 is supplied with a pre-mounted fixing panel ⑨for wall mounting. It can optionally be mounted at

the opposite side of the housing. You do not need to remove the screws ⑫. Simply pull the fixing panel down,

take it off, attach it at the opposite side of the housing and push it back up again.

Installation of the connections of individual components

The connections for the tank line ⑤, the burner flow line ⑪and the burner return line ⑩differ in accordance with

Connections with female threads are not designed for flat packings. Please always use the enclosed O-rings for

this option - see Installation of the connections female thread G3/8

In all installation work, hold up with open-end spanner SW 24 at the integrally cast connecting

branch, or with the appropriate open-end spanner at the respective screwed connection. Avoid

any twisting or torsion of the device. Be careful with the plastic parts!

Installation of the connections with female thread G 3/8

Female thread G 3/8 acc. to EN ISO 228-1

O-ring (enclosed) = seal!

Single-screw connection, e.g. screwed plug

EN ISO 1179-4 or prEN 12514-4:2009 shape

Installation of a screwed connection with brass or steel cutting ring (for your information)

Component

Connection via

Explanations

GS Pro-Fi 3

in RVS 6, 8, 10, or 12, optionally

available as factory-mounted version Screwed connection with brass or steel

cutting ring acc. to EN ISO 8434-1

Connection Pipe or socket piece of the connecting

hose line with 6, 8, 10, or 12 mm

outside diameter

•copper pipe, e.g. according to EN 1057

•Aluminum pipe, e.g. according to EN 1746

•Precision steel pipe, e.g. according to EN 10305-1,

steel cutting ring recommended!

IMPORTANT: Always use a reinforcing insert for copper and aluminum pipe!

Installation pursuant to the GOK Installation Manual for screwed connections with cutting rings according to

EN ISO 8434-1. Available for download from www.gok-online.de under “Service“.

Installation of the GOK Universal connection fitting type UA

The female thread can also take the GOK universal

connection set type UA, which corresponds to a

compression joint type G acc. to prEN 12514-4:2009

Annex D.

Piping used:

Copper pipe with outer diameter 6, 8 or 10 mm, e.g. acc.

to EN 1057

Installation acc. to Installation Manual for GOK clamp ring connection: UA Universal connection fittings.

Available for download from www.gok-online.de under “Service“.

Installation of male thread G 3/8 A with KN (60 ° inside cone) Recommended tightening torque: 10 Nm

GS Pro-Fi 3 Connecting branch to

housing, with inside cone KN

Pipe thread: cylindrical male thread G 3/8 in tolerance

class A according to EN ISO 228-1 with 60° inside cone

Connection Hose fitting with ball nipple

connection and union nut

Union nut with female thread G 3/8 according to

EN ISO 228-1, hose nozzle with ball seal