GVC-72000

8

OPERATION

WARNING: Always wear gloves, protective glasses and ear protection while

operating this machine.

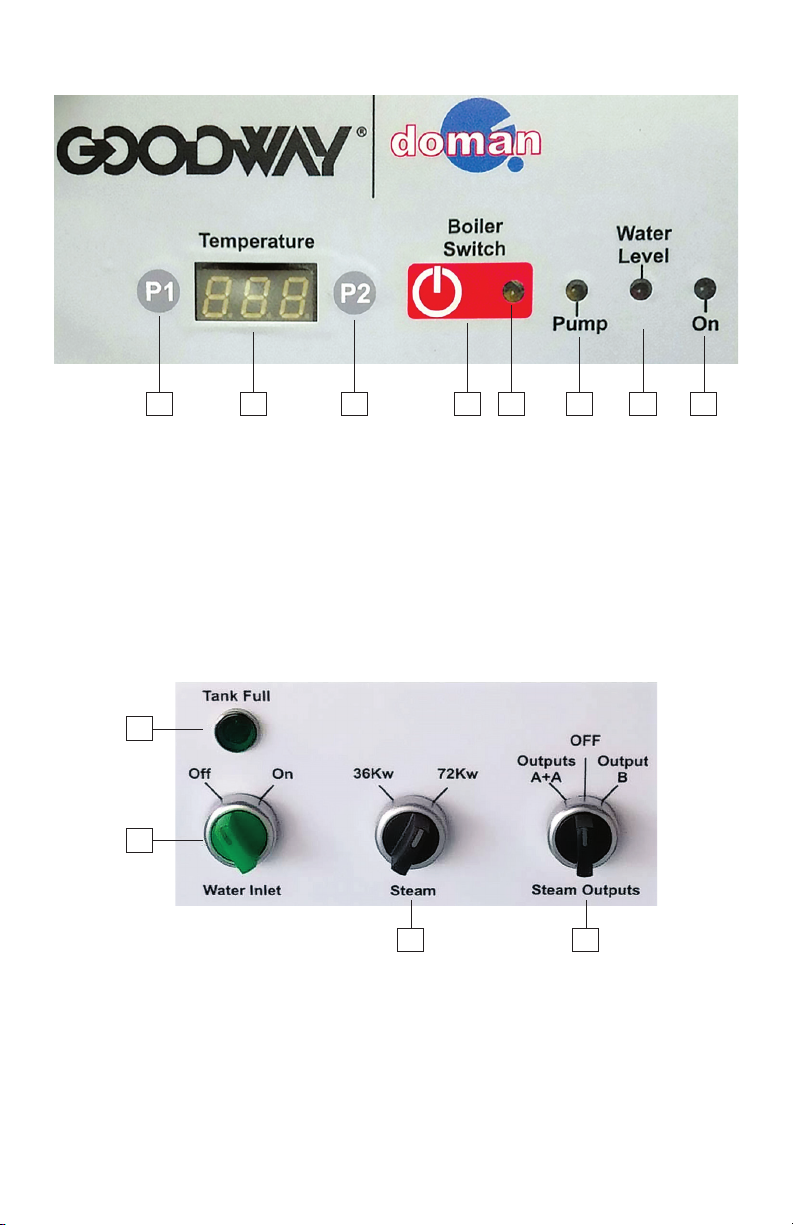

1. Turn the main power disconnect 8(Pic.1) to the ON position, Power ON LED

5.1 (Pic.2) will illuminate.

2. Open the water supply, and switch the Water Feed switch 4.2. to the ON

position. The tank will begin to ll; sensors ensure the correct water level. The

internal water tank is relled automatically and continuously.

CAUTION: Never switch ON the Water Feed Switch 4.2. (Pic.1) if the machine is

not connected to a water hose. This would cause water to ow out of the tank and

onto the oor. When done working, turn the Water Feed Switch 4.2. (Pic.1) OFF and

disconnect the water hose.

3. Push the boiler ON button 5.5 (Pic.2), the pump will start lling the boiler and

LED 5.3 (Pic.2) lights up.

4. When the pump stops LED 5.3 (Pic.2) goes out and the heating phase begins,

lasting approximately 5 minutes. During the heating phase, LED 5.4 (Pic.2) will

continue to blink.

5. When LED 5.4 (Pic.2) stops blinking and stays on, the machine is ready for

use. During use this light will often blink to show that the heating elements are

cycling on.

6. Insert the hose into the hose connection socket 1, 2 or 9 (Pic.1) (depending on

the application), ensuring that it is securely tted.

7. Fasten accessories to lances by rmly pushing them on to the tip (nozzle)

3.3 (Pic.3)

8. Pull the trigger 3.1 (Pic.3) on the hand-grip to start the steam output and direct

the steam jet towards the area to be cleaned.

9. Control steam output by selecting the two hose output ‘A-A’ or single hose

output ‘B’ on the steam output selection switch 4.4. (Pic.1).

10. With the output power selection switch 4.3. (Pic.1), change between 36kW and

72kW power output (one hose or both hoses).

NOTE: When knob 4.3. (Pic.1) is in the 36kW position, steam will only be released

from position 1. When knob 4.3. (Pic.1) is in the 72kW, steam will be released from

both 1 and 2 outputs OR the optional hose that connects to port ‘B’, NOT both.

NOTE: Before beginning steam cleaning operations, evacuate the condensation

left inside the steam hose into a bucket or other suitable place.

WARNING: In case of danger, injury of the operator, leakage of steam or anything

that makes it difcult to regularly turn the machine off, immediately hit the

emergency OFF button 3 (Pic.1). The switch will remain in the off position until

manually reset by turning the switch so that it pops back up! Reset ONLY after

having removed the cause of malfunction. See the troubleshooting section!