GENERAL INFORMATION

The purpose of this manual is to assist

you in installing, operating and main-

taining your mechanical fuel meter�

Please take a few moments to read

these instructions before installing and

operating your fuel meter�

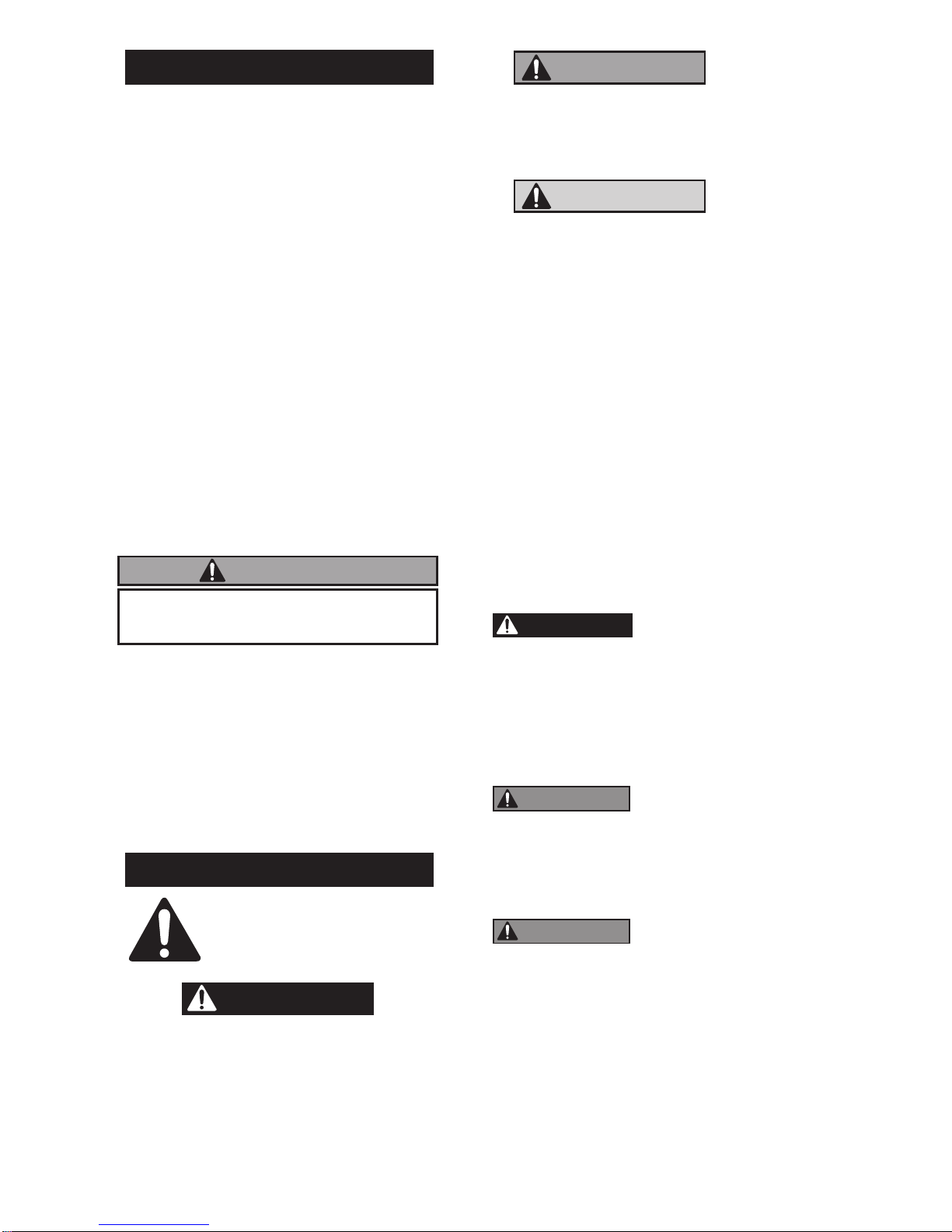

The MR 5-30 Mechanical Fuel Meter is

designed for the eld measurement of

thin viscosity petroleum fuels only and

intended for use with pump systems

in the 5 to 30 GPM or 19 to 114 LPM

ow range (not intended for gravity

ow systems). Using mechanical gears,

these meters translate ow data from a

nutatingdiscintocalibratedunitswhich

are indicated on the face of the meter�

Thismeterisfactorycalibrated forkero-

sene grade (JET A). Field calibration

feature is available for other uids, see

Calibration section�

For ground-based refueling only.

Do not use in or on the aircraft.

Use this meter with aviation gasoline

(AVGAS 100LL) and kerosene grade

(JET A).

Do not use this equipment for dis-

pensing any uids other than those

for which it was designed. To do so

may damage the meter and will void

the warranty.

SAFETY INSTRUCTIONS

The following safety

alert symbols are used

in this manual.

DANGER

DANGER indicates a hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous

situation which, if not avoided, may

result in minor or moderate injury.

It is your responsibility to:

• know and follow applicable na-

tional, state and local safety codes

pertaining to installing and operat-

ing electrical equipment for use

with ammable liquids.

• know and follow all safety precau-

tions when handling petroleum

fuels

• ensure that all equipment op-

erators have access to ade-

quate instructions concerning

safe operation and maintenance�

1�

DANGER

Observeprecau-

tions against re or explosion when

dispensing fuel� Do not operate

the meter in the presence of any

source of ignition including run-

ning or hot engines, lighted ciga-

rettes, or gas or electric heaters�

2�

WARNING

Anycomponents

such as hose, nozzle, or pump

added to your meter must be

statically grounded and approved

for use with petroleum fuels�

3�

WARNING

Avoidprolonged

skin contact with petroleum fuels�

Use protective goggles, gloves,

and aprons in case of accidental

splashing or spillage� Change

saturated clothing and wash skin

contact areas promptly with soap

and water�

2

WARNING