2307212

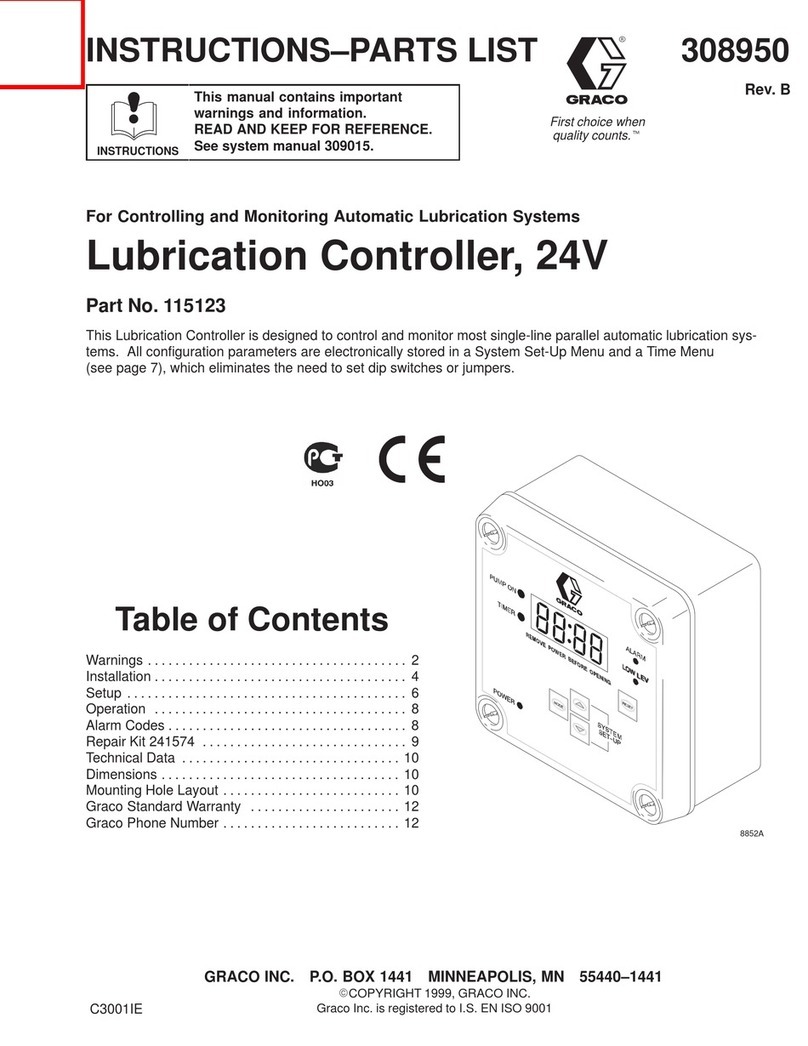

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Charts 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

WARNING

PRESSURIZED EQUIPMENT HAZARD

Spray from the gun, hose leaks, or ruptured components can splash fluid in the eyes or on the skin

and cause serious injury.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Follow the Pressure Relief Procedure on page 5 whenever you: are instructed to relieve the

pressure; stop spraying; clean, check, or service the equipment; and install or clean the fluid

nozzle.

Tighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

INSTRUCTIONS

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

This equipment is for professional use only.

Read all the instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component.

Use fluids that are compatible with the equipment wetted parts. See the Technical Data section of

all the equipment manuals. Read the fluid manufacturer’s warnings.

Never use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in these regulators. In the event that there is a diaphragm failure, a

serious chemical reaction could occur, with the possibility of explosion.

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

307212 complies with all applicable local, state, and national fire, electrical, and other safety

regulations.