Operation

10 308778ZAG

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1. Shut off the fluid supply to the meter.

2. Shut off all electrical power to the fluid system.

3. Follow the Pressure Relief Procedure for your fluid

system dispensing device.

Flow Meter Function

This is a positive displacement, gear flow meter. The

gear flow meter is highly accurate, even with low flow

rates. The fluid flowing through the meter rotates the

gears. The gear tooth is picked up by a sensor device,

which produces an impulse for every gear tooth passing

by.

Recommended Usage

• See the Technical Specifications on page 21 for

fluid and ambient temperature limits.

• Only use the flow meter with fluids that are

compatible with the “Wetted Parts” listed in the

Technical Specifications.

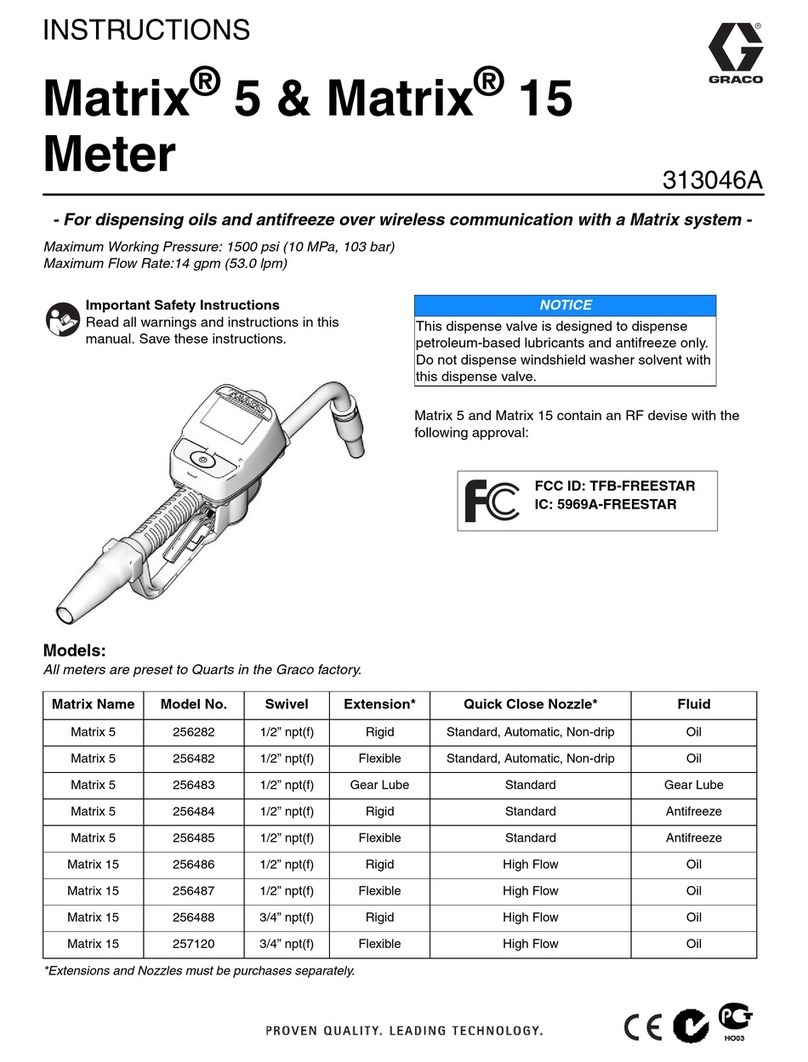

Flow Volume Range

The G3000v G3000A, G250, and FX250 meters flow

volume range is 0.02-1.0 gal./min. (75-3800 cc/min.).

The G3000HR and G250HR meters flow volume range

is 0.01-0.5 gal./min. (38-1900 cc/min.).

The S3000 solvent meter flow volume range is

0.01-0.42 gpm (38-1600 cc/min).

Checking the Meter Accuracy

1. To check the accuracy of the meter, turn your gun

fan and atomizing air off, then trigger the fluid into a

graduated cylinder; dispense at least 500 cc of fluid.

2. Measure the volume of fluid in the beaker in

cubic-centimeters (cc) and read the volume on the

flow meter monitor.

G3000, G3000A, G250, and FX250: If the flow

meter scale factor is not between 0.112-0.140

cc/pulse, follow the cleaning procedure on page 13,

then recalibrate the flow meter.

G3000HR and G250HR: If the flow meter scale

factor is not between 0.05-0.07 cc/pulse, follow the

cleaning procedure on page 13, then recalibrate the

flow meter.

S3000: If the solvent meter scale factor is not

between 0.019-0.022 cc/pulse, follow the cleaning

procedure on page 13, then recalibrate the flow

meter.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

Do not exceed the maximum working pressure of

your meter or any component or accessory in your

system.

NOTICE

The flow meter gears and bearings can be damaged

if they rotate at excessive speeds. To avoid high

speed rotation, open the fluid valve gradually. Do not

over-speed the meter with air or fluid. Do not use

compressed air to rotate flow meter gears. Do not

exceed the meter’s maximum flow rate.