(B) Burst pulse output (Phase-A wave advances when the spindle is retracted.)

When the response speed reaches the speed limit of real-time pulse output, the linear gage will switch

its signal output form to that consisting of burst pulses. At this time, these burst pulses will be such

2-phase square wave signals that are forcibly created from the internal clock so the minimum

edge-to-edge interval in their output is smaller than the normal real-time pulse output. The burst pulses

will not always be outputted so as to exactly reflect the actual motion and the delay in signals also

becomes larger, but the counting values will be still valid as long as this output form continues.

(1) Output condition: 250 mm/s *4 < Spindle moving speed ≤Gage response speed *6

(2) Minimum edge-to-edge interval of output pulses: Tb (See the following table.)

(3) Output delay time *5: ●When feeding the spindle forward = Max. 5 μs

●When returning the spindle backward = Max. 10 μs

(C) Error output

The pulse generation circuit may sometimes overstep its response limit, if the output wave is subject to

extreme disturbance due to vibration or impact in the gage unit, or if the spindle moves faster beyond

the output limit of burst pulses. However, at this time, as the linear gage will automatically switch its

output signal form from burst pulses to error pulses and also synchronize Phase A and Phase B of the

2-phase square wave signals, the user can make use of this facility for error detection.

(1) Output condition: The gage will be identified as error under the following conditions and

produce its output in one of the above described special patterns.

●Gage response speed *6 < Spindle moving speed

●At a disturbance such as noise interference, vibration, etc.

(2) Minimum edge-to-edge interval of output pulses: Te (See the following table.)

Minimum edge-to-edge interval / pulse width under each condition

Resolution Tr (for real-time pulse) Tb (for burst pulse) Te (for error pulse)

1μm 1μs 0.5μs 0.25μs

0.5μm 1μs 0.25μs 0.25μs

*4: The actual limit of real-time pulse output will be depreciated to this value. This is because actual detection

signals unavoidably contain acceleration components in association with the spindle motion as well as

error components from a minute noise included in the signal itself. As a result, some burst pulses at a

speed below the ideal conditions (i.e. ideal signal form at constant speed) may be generated.

*5: Output delay time: Time until the counting pulse catches up the spindle position

*6: Gage respond speed: Refer to the section of specifications of the Users Manual.

IMPORTANT

zSince any output during error can not be used as the attribute data, it is necessary to detect the error

condition at the reception circuitry side.

zIt is recommended to design user circuitry based on an IC chip that is capable of counting at 5 Mcps

(equivalent to a square wave of 1.25 MHz) or greater.

zWhen detecting the origin point position in this gage, carefully observe the following to detect the origin

point with as good repeatability as possible.

zOrigin point detection should always be performed in the same direction. (Bidirectional detection of the

origin point will exhibit hysteresis just for Xz.)

zThe spindle moving speed at the origin detection should be 300 mm/sec or less. Pass the spindle through

the origin while keeping either of retracting or releasing direction.

5) Input connector and recommended input circuit connector: PRC05-R8F (TAJIMI MUSEN)

6) Cable extendible length: The cable can be extended up to 20m using the extension cable (optional).

6. Maintenance

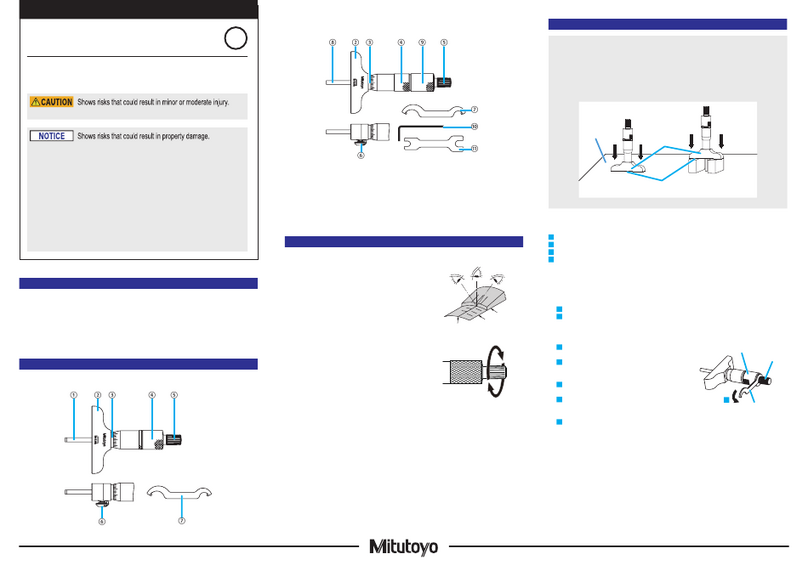

1) Replacing the contact point

Fit the supplied key spanner in the keyway of the spindle, then detach or

attach the contact point by pinching it with a wrench, etc.

IMPORTANT

If torque is applied to the sensor inside through the spindle,

damage or malfunction in the sensor may result. Be sure to

fix the spindle using the key spanner.

2) Replacing the rubber boot

Preventive replacement before being damaged is recommendable.

(The rubber boot is available as an optional accessory.)

(1) Remove the old rubber boot, then eliminate the dust and dirt in the grooves (part A) of the stem and spindle.

(2) Insert a rubber boot between the stem and contact point, directing the greater inside diameter end to the stem.

(3)Apply a small amount of silicone adhesive to the grooves (part A), and seal both ends of the rubber boot.

IMPORTANT

If the adhesive is applied to the spindle, the spindle will not slide properly. Great care must be exercised.

7. Specifications

Order NO. 542-164 542-165 542-166

Model No. LGF – 110ZL - B LGF – 125ZL - B LGF – 150ZL - B

Resolution 1μm

Output signal pitch 4μm

Minimum edge interval 500ns

Order NO. 542-174 542-175 542-176

Model No. LGF – 0510 ZL - B LGF – 0525ZL - B LGF – 0550ZL - B

Resolution 0.5μm

Output signal pitch 2μm

Minimum edge interval 250ns

Measuring range 10mm 25mm 50mm

Contact point downwards 1.2 N or less 4.6 N or less 5.7 N or less

Contact point horizontal 1.1 N or less 4.3 N or less 5.3 N or less

Meas.

force

Contact point upwards 1.0 N or less 4.0 N or less 4.9 N or less

Origin Position Approx. 3mm from BDC Approx. 5mm from BDC

Stem Diameter Φ8 Φ15

Specifications common to all series

●Accuracy (at 20℃): (1.5 + L/50)μm L = Measured length in mm

●Quantizing error: ±1 count

●Origin repeatability (at 20°C): σ≤0.5 μm (if the spindle passes through the origin point at a constant speed

of 300 mm/sec or less and in the same direction)

●Positional sensor: Photoelectric transmission linear encoder

●Response speed: 1.5m/s *7

●Output method: 90°phase differential square wave (compatible with RS-422A)

Refer to the above table for Output Signal pitch and Minimum edge interval

●Contact point: Φ3 carbide ball (Thread: M2.5x0.45)

●Bearing type: Stroke ball bearing

●Protection level: IP66

●Output cable length: 2m(directly wired from the gage)

●Operating temperature (humidity): 0 to 40 ℃(20 to 80%RH, with no condensation)

●Storage temperature (humidity): -10 to 60 ℃(20 to 80%RH, with no condensation)

●Accessory: No. 538610 Key spanner for contact point replacement (10mm type)

No. 210187 Key spanner for contact point replacement (25/50mm type)

*7: In the case of 50mm stroke type, an over speed error may occur depending on the spindle retraction

amount, if the contact point is released freely after it is retracted.

8. Optional Accessories

●Extension cable for origin mark (5m) : No. 02ADF260

●Extension cable for origin mark (10m) : No. 02ADF280

●Extension cable for origin mark (20m) : No. 02ADF300

●Rubber boot (for 10mm type) : No. 238772

●Rubber boot (for 25mm type) : No. 962504

●Rubber boot (for 50mm type) : No. 962505

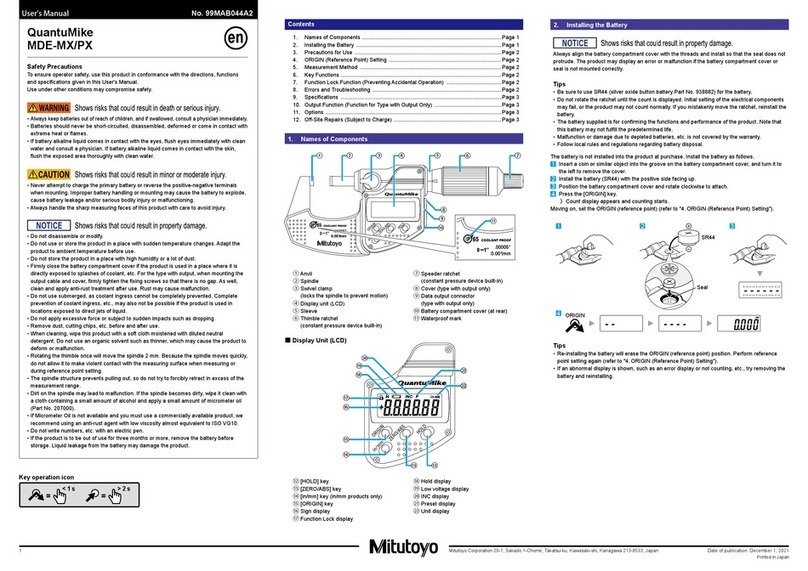

If the thrust stem and tightening nut are used, the gage mount fixture needs only Φ9.5 or Φ18 hole to be

drilled, and also the gage can be mounted firmly and easily. (see below.)

●Thrust stem (for 10mm type) :No. 02ADB682

●Tightening nut (for 10mm type) :No. 02ADB682

●Dedicated spanner (for 10mm type) : No. 02ADB683

●Thrust stem (for 25/50mm type) :No. 02ADN371

●Tightening nut (for 25/50mm type) :No. 02ADB692

●Dedicated spanner (for 25/50mm type) :No. 02ADB693

=Example of use=

IMPORTANT

zBefore mounting the trust stem, be sure to secure the stem using the dedicated spanner (No.02ADB683/

No.02ADB693). Excessive force applied between the gage body and stem may cause damage to the

gage.

zM9 x 0.5/M14 x 0.5 screw are sued only for mounting the trust stem. Do not use them for other purposes.

Mitutoyo Corporation

Kawasaki、Japan

ΦA, ΦB

ΦA, ΦB51Ω

33pF

+5V

+5V 470pF 470pF

4.7kΩ

4.7kΩ

200Ω 1.8kΩ

ΦZ

GND GND

LGF output circuit Recommended input circuit

26LS32 or equivalent

+5V

+5V

GND GND

GND

ΦA

ΦB

ΦZ

ΔXz

Xz

ΔXz

1μm / 0.5μm

Tr (min.)

→Resolution

LGF-0510ZL-B

LGF-110ZL-B

LGF-0525ZL-B

LGF-125ZL-B

LGF-0550ZL-B

LGF-150ZL-B

Fixture width L: within 6 to 10.5mm

Fixture width L: within 10 to 13mm

LGF-0525ZL-B

LGF-125ZL-B

LGF-0550ZL-B

LGF-150ZL-B

LGF-0510ZL-B

LGF-110ZL-B

Thrust stem set (for 10mm type)

No.02ADB680

Thrust stem set (for 25/50mm type)

No.02ADN370

Te

min.

Phase B

Phase A

Key Way

Key spanner

(for replacing contact points)

( )(A)

Stem

Spindle Rubber boot Contact point

A

Key Way (A)(

A

)

Stem

Spindle Key Way Rubber boot Contact point

Thrust stem

(Optional accessories)

Dedicated s

anner

(Optional accessories)

Mounting nut

(Optional accessories)

Thrust stem / Mounting nut

Dimension between

hexagonal opposing sides

Thrust stem

(Optional accessories)

Dedicated spanner

(Optional accessories)

(Optional accessories)

Mounting nut

For 25mm stroke = (84.1)

For 50mm stroke = (124.9)

Thrust stem / Mounting nut

Dimension between

hexagonal opposing sides