2309712

ADVERTENCIA

L’injection de fluide constitue une lésion grave! Si un fluide haute

pression perce la peau, la blessure peut paraître comme une

«simple coupure». Mais il s’agit bien d’une lésion grave! Consulter

immédiatement un médecin.

Pour éviter les risques d’injection, toujours:

Bloquer le loquet de sécurité de la gâchette à la fin de la pulvérisation.

Pointer le pistolet loin de soi-même et toute autre personne à proximité

Décharger la pression avant de vérifier ou réparer une fuite.

Décharger la pression après la mise hors tension du pulvérisateur ou

à la fin de la pulvérisation.

Ne pas utiliser de composants dont la pression nominale est inférieure

à la pression maximale de service du système.

Ne jamais permettre aux enfants d’utiliser cet appareil. En cas de bles-

sure pour avoir utilisé cet appareil, consulter immédiatement un médecin.

Risque d’incendie et d’explosion imminent pendant la pulvérisation

ou le rinçage à pression de fluides inflammables dans une zone à mau-

vaise circulation d’air et en présence de gaz inflammables pouvant

s’allumer par une flamme nue ou des étincelles.

Pour éviter les risques d’incendie et d’explosion:

Manipuler les fluides à l’air libre ou dans une zone extrêmement

bien aérée.

Ne jamais utiliser de trichloroéthane 1,1,1, de chlorure de méthylène,

d’autres solvants à base d’hydrocarbures halogénés, ni de produits

contenant de tels solvants dans un équipement sous pression en

aluminium. Cela pourrait provoquer une réaction chimique avec risque

d’explosion.

Retirer, éteindre ou déboucher toute source d’inflammation, recouvrir

tout interrupteur mural avec du ruban adhésif. Ne pas fumer dans la

zone de pulvérisation.

Ne jamais remplir le réservoir d’essence lorsque le moteur est chaud

ou en marche.

Mettre à la terre le pulvérisateur, l’objet à pulvériser ainsi que les

seaux de peinture et de solvants.

Tenir le pistolet fermement contre la paroi d’un seau mis à la

terre lorsqu’on pulvérise dans le seau.

N’utiliser qu’un flexible pour peinture pulvérisée sans air.

Ne jamais mettre en marche un moteur dans une zone fermée.

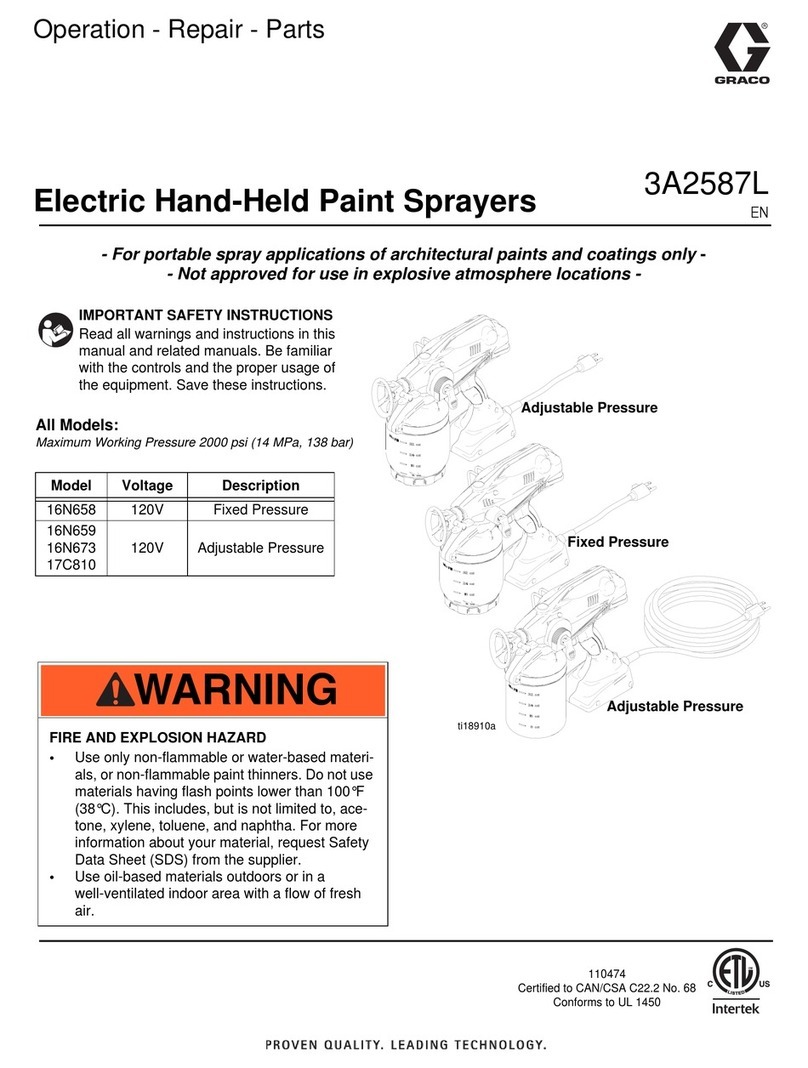

Fluid injection and high pressure hazard: High pressure spray or

leaks can inject fluid into the body.

To help prevent injection, always:

Engage trigger safety latch when not spraying.

Keep clear of nozzle and leaks.

Never spray without a tip guard.

Do PRESSURE RELIEF if you stop spraying or begin servicing

sprayer.

Do not use components rated less than sprayer Maximum

Working Pressure

Never allow children to use this unit.

If high pressure fluid pierces your skin, the injury might look like

“just a cut”. But it is a serious wound! Get immediate medical atten-

tion.

Fire and explosion hazard: Solvent and paint fumes can ignite or

explode.

To help prevent a fire and explosion:

Use only in an extremely well ventilated area.

Eliminate all ignition sources; such as pilot lights, cigarettes and

static arcs from plastic drop cloths. Do not plug or unplug power

cords or turn lights on or off in spray area.

Ground Sprayer, object being sprayed, paint and solvent pails.

Hold gun firmly to side of grounded pail when triggering into pail.

Use only conductive airless paint hose.

Do not use 1,1,1–trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminum equipment. Such use could

result in a chemical reaction, with the possibility of explosion.

WARNING

MISE EN GARDE

Pueden ocurrir incendios y explosiones cuando se pulveriza fluido in-

flamable o cuando se lava con este tipo de fluido en un área donde la

circulación de aire es deficiente y los vapores inflamables se pueden en-

cender al contacto con el fuego o chispas.

Para prevenir incendios y explosiones:

Use en espacios abiertos o en un área muy bien ventilada.

No utilice nunca tricloretano–1,1,1, cloruro de metileno, u otros di-

solventes a base de hidrocarburos halógenos o fluidos que contengan

tales disolventes en un equipo a presión de aluminio. El uso de estas

sustancias puede provocar una intensa reacción química, con riesgos

de explosión.

Retire, apague o desconecte todas las fuentes de ignición; asegure el

interruptor de la pared con cinta. No fume en el área de pulverización.

Nunca llene el estanque de combustible mientras el motor esté en

marcha o caliente.

Ponga a tierra el pulverizador, el objeto que recibe el chorro pulverizado,

las cubetas de pintura y disolvente.

Sostenga firmemente la pistola a un lado de la cubeta puesta a

tierra cuando dispare dentro de ella.

Use solamente mangueras para pintura conductora sin aire.

Nunca haga andar el motor dentro de un área cerrada.

¡La inyección de fluido en la piel es una lesión seria! Si fluido de

alta presión le penetra la piel, la lesión podría parecer “sólo un

corte”. ¡Es una lesión seria! Consulte de inmediato al médico.

Para prevenir la inyección en la piel, siempre:

Enganche el seguro del gatillo cuando no use el pulverizador.

No apunte la pistola ni a sí mismo ni a los demás.

Alivie la presión antes de inspeccionar o reparar cualquier filtración.

Alivie la presión cuando apague el pulverizador o deje de usarlo.

No use componentes cuya capacidad nominal sea inferior a la

presión máxima de operación del sistema.

No permita que niños usen esta unidad. Si se lesiona usando este

equipo, sométase de inmediato a tratamiento médico.

ADVERTÊNCIA

Poderá ocorrer incêndio e explosão quando for pulverizado ou injetado

líquido inflamável numa área onde houver má circulação de ar; vapores

inflamáveis poderão incendiar-se a partir de uma chama ou fagulhas a

descoberto.

Para ajudar a evitar incêndio e explosão:

Utilize no exterior ou numa área muito bem ventilada.

Não utilize 1,1,1–tricloroetano, cloreto de metileno, outros solventes de

hidrocarbonetos halogenados ou líquidos contendo tais solventes em

equipamento de alumínio pressurizado. Tal utilização poderá resultar

numa reação química, com possibilidade de explosão.

Retire, elimine ou desligue todas as fontes de ignição; coloque fita

adesiva na tomada da parede. Não fume na área de pulverização.

Nunca abasteça o depósito de combustível com o motor em funciona-

mento ou quente.

Ponha em contato com a terra o pulverizador, o objeto a ser pulveriza-

do, e os baldes de tinta e de solventes.

Segure a pistola firmemente de encontro ao lado de um balde em contato

com a terra, quando estiver descarregando para dentro do mesmo.

Utilize somente tubos flexíveis condutores para pintura a alta pressão.

Nunca faça funcionar o motor numa área fechada.

A injeção de líquido é um ferimento grave! Se o líquido a alta pres-

são penetrar na sua pele, o ferimento poderá parecer “simplesmente

um corte”. Mas é um ferimento grave! Procure o médico imediatamente.

Para ajudar a evitar injeção de líquido, faça sempre o seguinte:

Engate o trinco de segurança do gatilho quando não estiver pulveri-

zando.

Sempre aponte a pistola para longe de você mesmo(a) ou de outras

pessoas.

Alivie a pressão antes de verificar ou reparar qualquer vazamento.

Alivie a pressão quando desligar o pulverizador ou parar de pulverizar.

Não utilize componentes classificados para uma pressão nominal

inferior à pressão máxima de trabalho dos sistemas.

Nunca permita que crianças utilizem esta unidade. Se sofrer algum

ferimento durante a utilização deste equipamento, procure o médico

imediatamente.