€QU/PMENT

MISUSE

HAZARD

General

Safety

overpressurizing, modifying parts, using incompatible

Any misuse of the spray equipmant or accBsBories, such as

chemicals and fluids, or using wornor damagedparts, can

cause them torupture and

result

inafluid injection, splashing

explosionor property damage.

in

the ayes or onthe skin, or other serious bodily injury, fire,

could cause

it

to malfunction.

NEVER alter or modify any part of this equipment; doing

so

worn or damaged pans immediately.

CiECK all sprayequipment regularly and repairorreplace

regardingthe use of protective clothing and equipment.

Readandfollow thefluid andsolvent manufacturer'sliterature

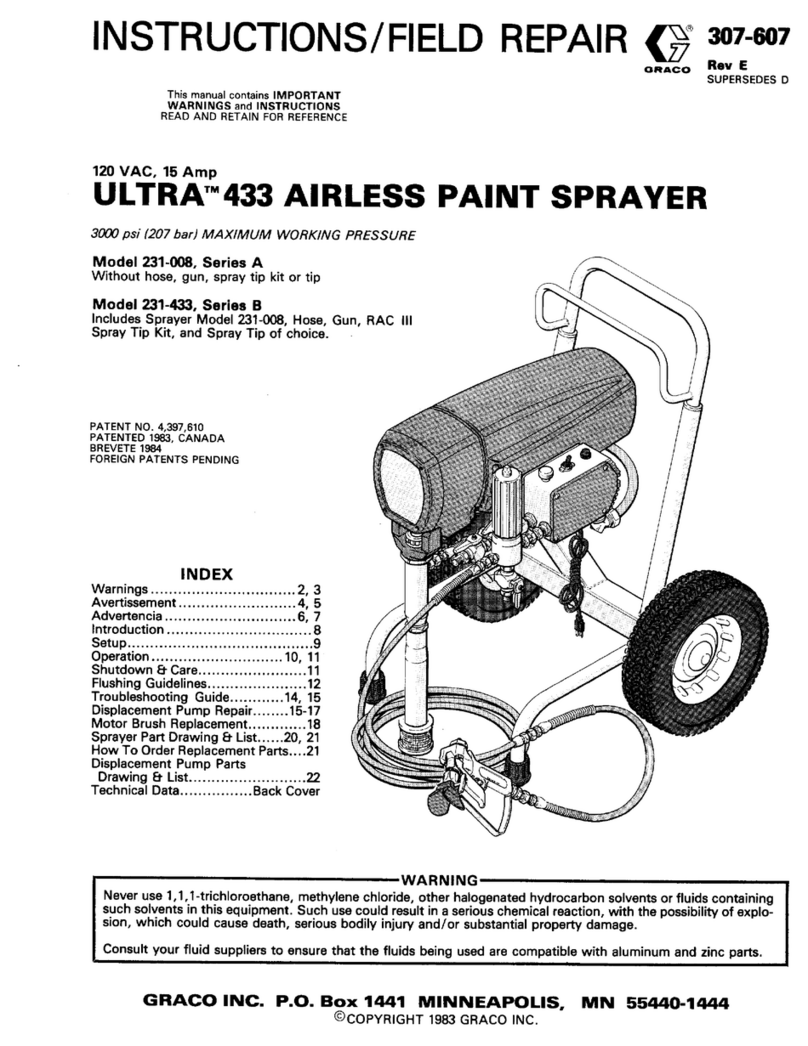

System

Pressure

This sprayer can develop

2750

psi (190,barJ MAXIMUM

accessoriesare rated to withstand the maximum working

WORKINGPRESSURE. Be sure that all spray equipmentand

pressureof this sprayer.

DO

NOT exceedthe maximumwork-

system.

ing pressure of any component oraccessory used

in

the

Fluid

and

Solvent

Compatibility

BE SUREthat all fluids andsolventsusedare chemicallycom-

the back cover. Always read the fluid and solvent manufac-

patible with the wettedparts shown inthe Technical Dataon

turer's literature before using them

in

this sprayer.

HOSE SAFETY

High pressure fluid inthe hoses can

be

vary dangerous.

If

the

damageor misuse, the highpressure sprayemittedfrom

it

can

hosa develops aleak, split or rupturedue toany kind of waar,

cause a

fluid

injection injury or other serious bodily injury or

property damage.

ALL FLUID HOSES MUST HAVESPRING GUARDS1The

spring guards help protect the hose

from

kinks

or

bends

at

or

close to thecoupling which can result in hose rupture.

TIGHTENall fluidconnectionssecurely beforeeach use.High

pressurespray to be emitted from the coupling.

pressure fluid Fan dislodge aloose coupling or allow high

NEVER use a damaged hose. Before each use, check the en-

tirehosefor cuts, leaks, abrasion.bulging cover, or damage or

exist, @lace the hose immediately,

DO

NOT try to recouple

movement of the hose couplings. If any of these conditions

highpressure hose ormend

it

with tape or anyother device. A

repaired hosecannot contain the high pressure fluid.

HANDLE AND ROUTE HOSES CAREFULLY.

Do

not pull on

hosestomove equipment.

Do

not usefluids

or

solventswhich

are not compatiblewith the innertube and cover of the hose.

00

NOT exposeGracohose to temperaturesabove 180°F

182"CI or below

4OF

(4'C).

Hose

Grounding Continuity

Proper hosegrounding continuity is essentialto maintaininga

groundedspray system. Checkthe electrical resistanceof your

air andfluid hoses

at

least once a week.If your hose doesnot

havea tagon

it

which specifies the maximum electrical

resistance, contact the hose supplier or manufacturerfor the

maximum resistance limits. Use

a

resistance meterin the ap-

propriate range for your hose to check the resistance. If the

resistanceexceeds the recommended limits, replace

it

im-

your system hazardous. Also readFIRE

OR

EXPLOSION

mediately. An ungroundedor poorly groundedhosecanmake

HAZARD.

FIRE

OR

EXPLOSION.HAZARD

through the pumpand hosa. If every part of the spray equlp-

Static electricity is created by the high velocity flow of fluid

ment is not properly grounded, sparking may occur, and the

systemmay become hazardous. Sparking mayalso occur

when plugging in or unplugging a power supply cord. Sparks

can ignite fumes from solvents and the fluid being sprayed.

dust particlesand other flammable substances, whether you,

are spraying indoors or outdoors, and can cause a fire or ex-

plosion andserious bodily injury and property damage.

Always plug the sprayer into an outlet at least

20

feet

16

m)

away from the sprayer and the spray area.

Do

not plug in or

any chanceof igniting fumes still in the air.

unplugany powersupply cords

in

thesprayarea whenthereis

while using this equipment, STOP SPRAYINGIMMEDI-

If you experience any static sparking

.or

even a slight shock

ATELY. Check the entire system for positive grounding. Do

not usethe systemagain until theproblemhas beenidentified

and corrected.

Grounding

To reducethe risk of static sparking, ground the sprayer and

all other spray equipment used or located

in

the sprayarea.

CHECK your local electrical code for detailed grounding

in-

structions for your area and type of equipment. BE SURE to

ground all of this spray equipment:

1.

2.

3.

4.

5.

6.

7.

Sprayer: plug the power supply cord, or extension cord,

eachequippedwithanundamagedthree-prongplug, into

aproperlygroundedoutlet.

Do

not useanadapter. All ex-

tension cords must have three wires and be rated for 15

amps.

Fluid

hoses: use only groundedhoseswith a maximumof

500

feet 1150 mJcombinedhoselengthtoensure ground-

ing continuity. Refer to Hose Grounding Continuity.

Spray

gun:

obtain grounding through connection to

a

properly grounded fluid hose and sprayer.

Objectbeing sprayed: accordingto local code.

Fluid

supply

container: according to local code.

All

solvent pails used when flushing, according to locsl

code. Useonlymetalpails, which areconductive.

DG

not

placethe pailona non-conductivesurface, suchas papor

or cardboard, which interrupts the grounding continuity.

To

maintaingrounding coptinuity when flushing or reliev-

ingpressure, alwaysholda metalpanof the gun firmlyto

the side of agrounded metalpail, then trigger the gun.

flushing

Safety

Reduce the risk of

a

fluid iniection injury, static sparking, or

splashing byfollowing the flushing procedure given on page

page

2,

andremovethe spray

tip

beforeflushing. Holdametal

12

of this manual. Followthe Pressure ReliefProcedure on

part

of

the gun firmlytothe side of agroundedmetalpailand

USB

the lowest possible fluid pressureduring flushing.

...

MOVING PARTS HAZARD

Moving pans can pinch or amputate your fingers or other

body pans. KEEPCLEAR

of

moving panswhenstarting or

operating the sprayer. Unplug

the

sprayer,and follow the

Pressure ReliefProcedureon page2 toprevent

it

from star-

ting accidentally.

IMPORTANT

ticularly the General Standards, Pan 1910, and the Construction Standards, Part 1926-should be consulted.

UnitedStatesGovernmentsafetystandardshave beenadopted underthe OccupationalSafetyand HealthAct, Thesestandards-par.

307-735

3