Graco AKA 420 User manual

Other Graco Paint Sprayer manuals

Graco

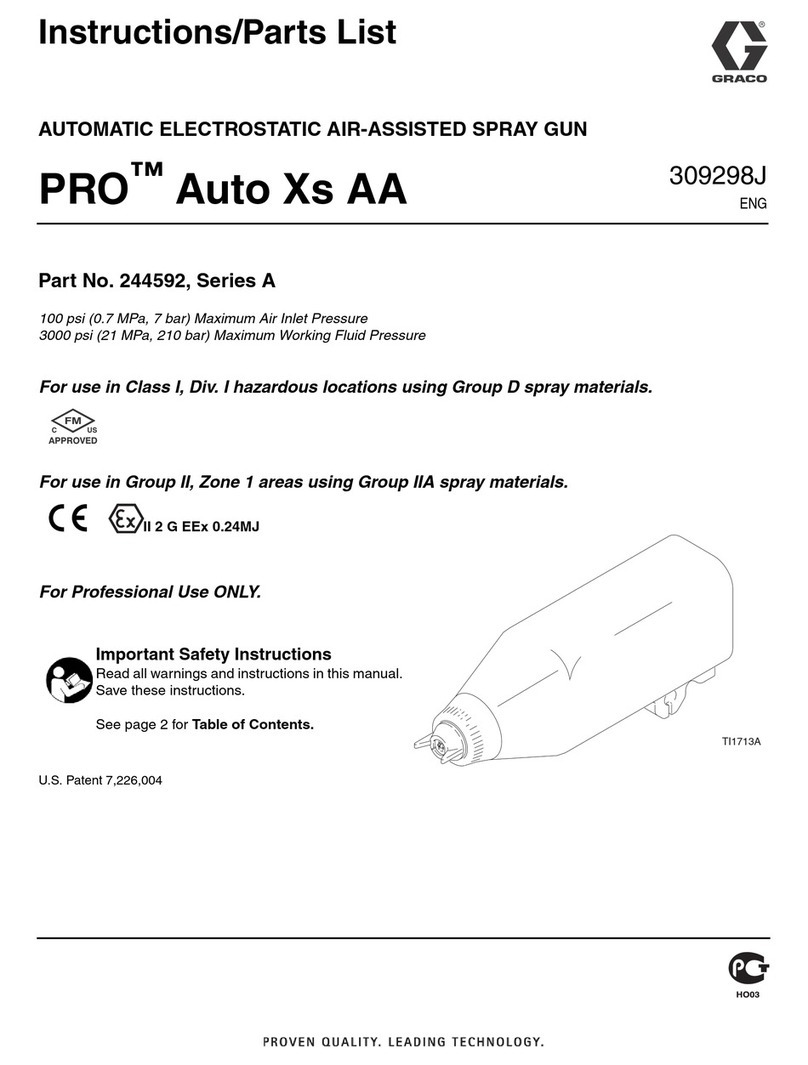

Graco 244592 Operation manual

Graco

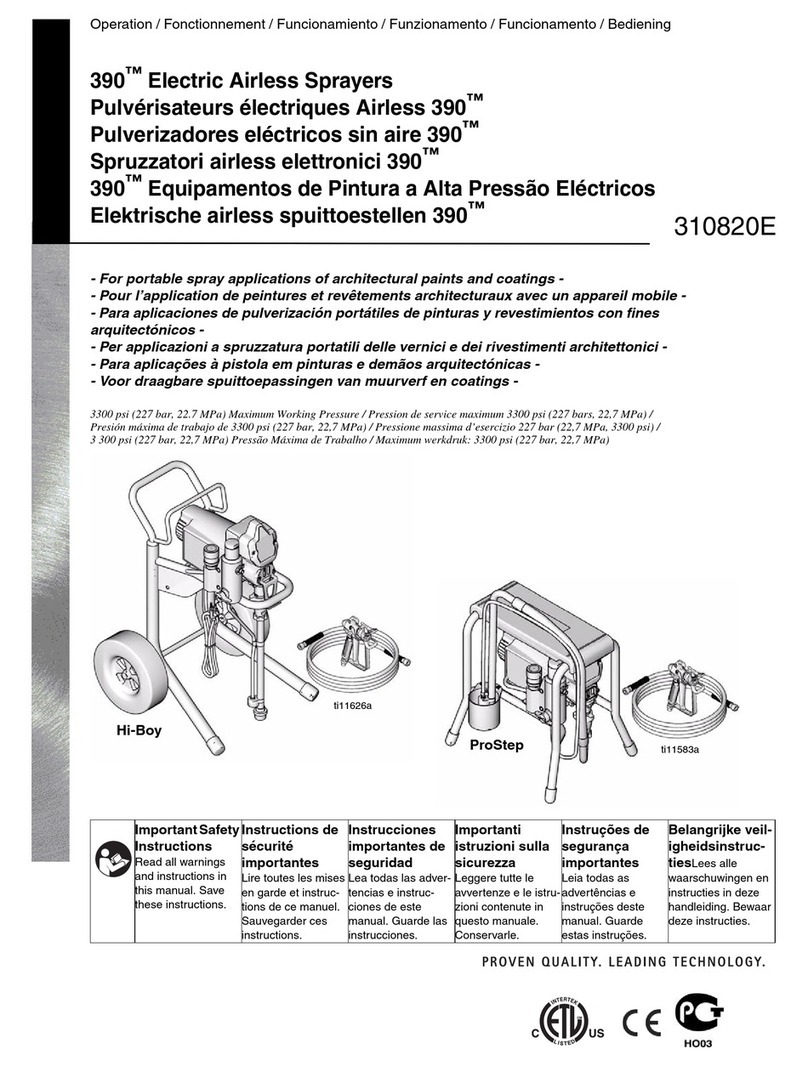

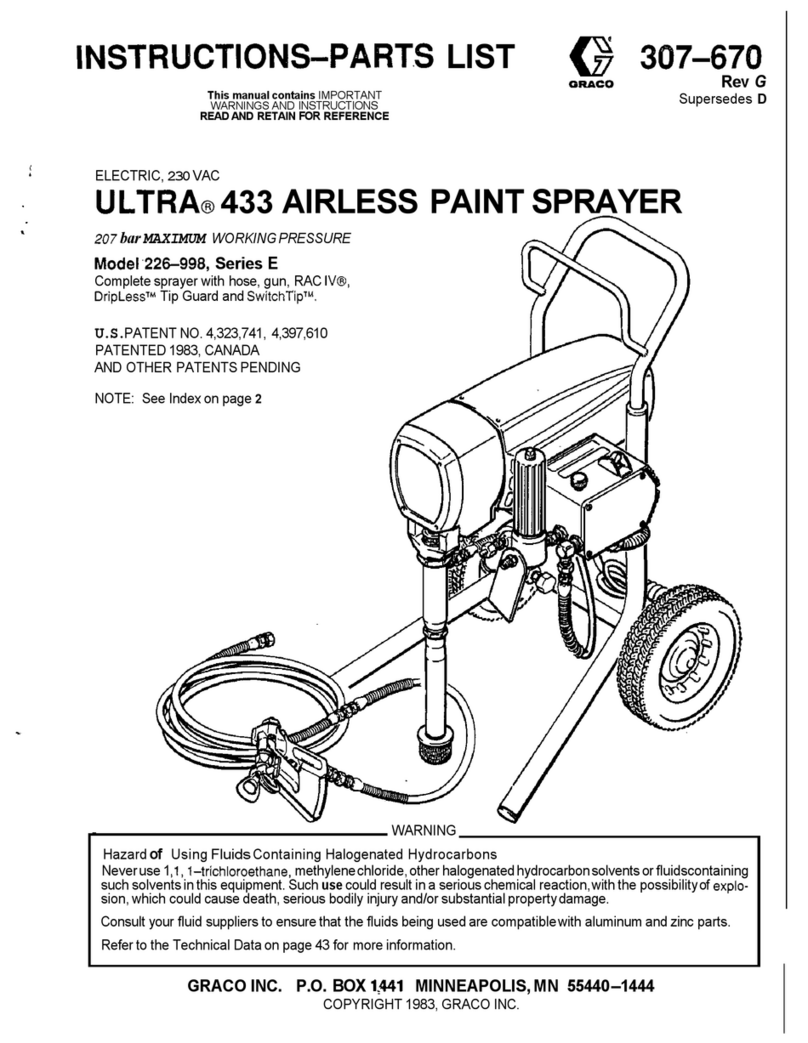

Graco Series E Operation manual

Graco

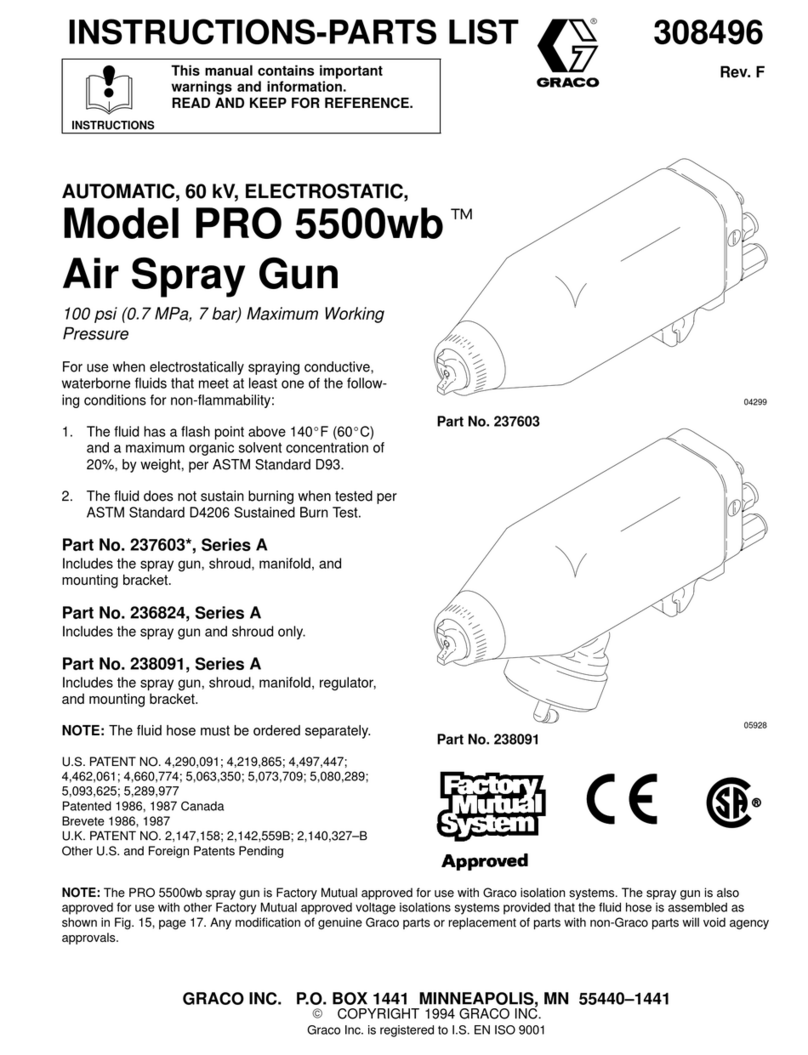

Graco PRO 5500wb Operation manual

Graco

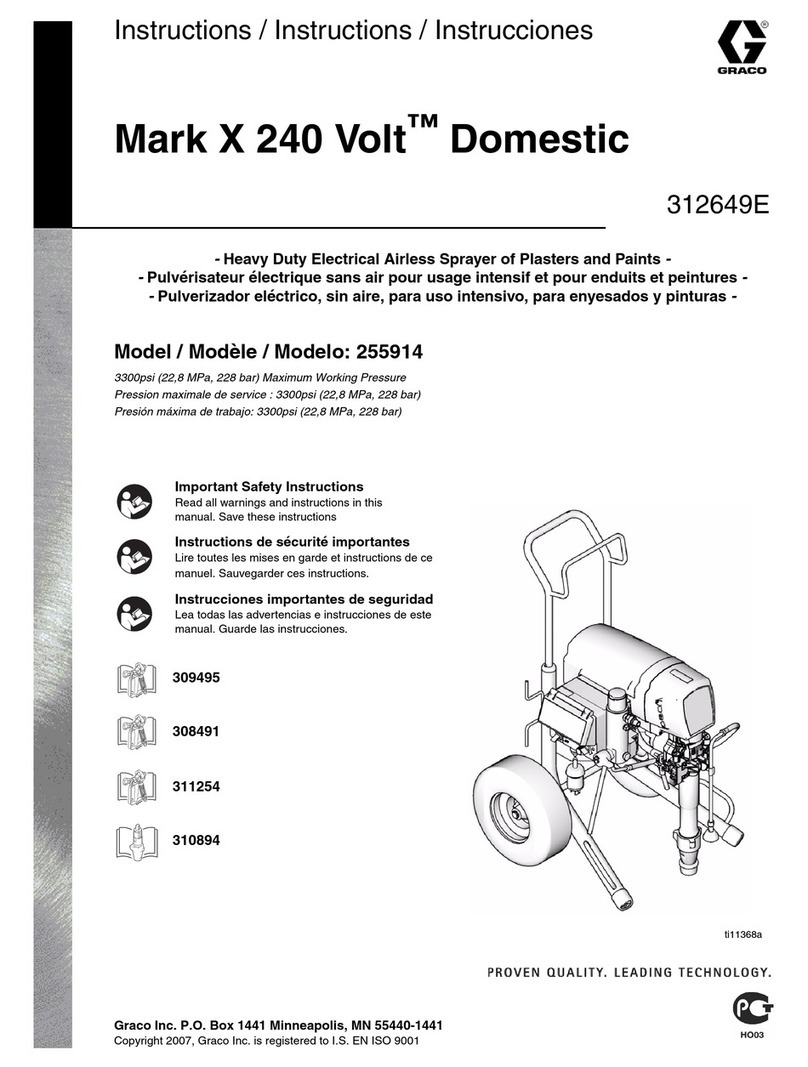

Graco Mark X 240 Volt User manual

Graco

Graco XT Series User manual

Graco

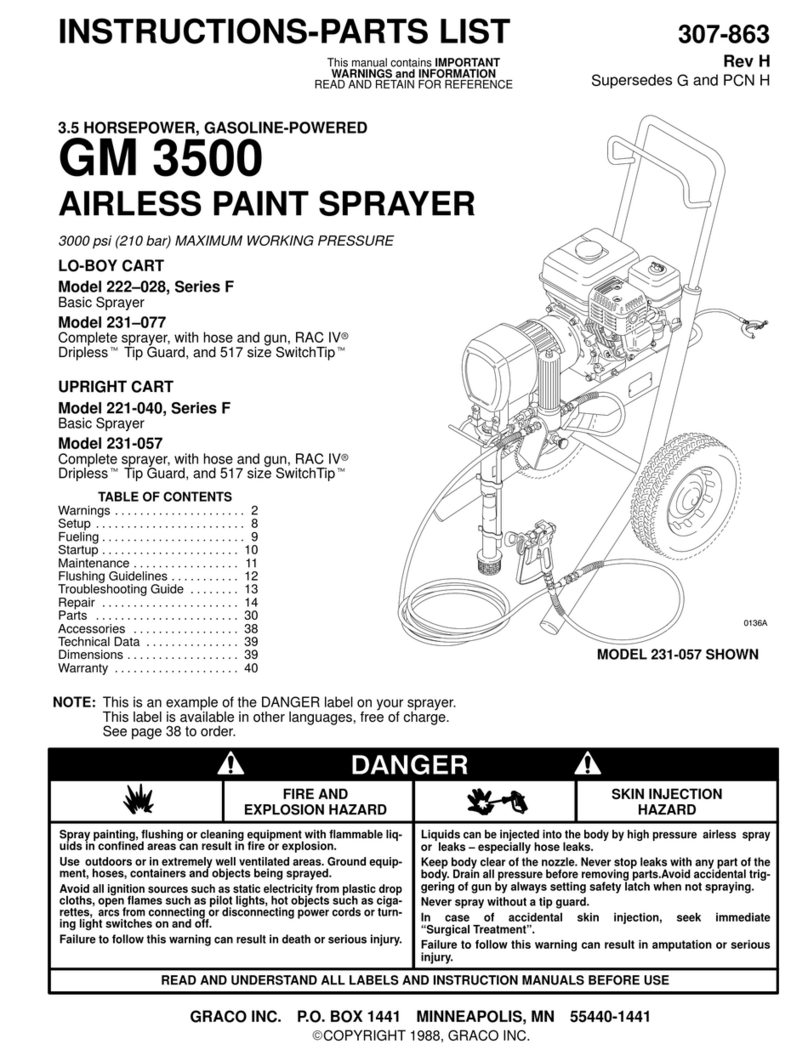

Graco GM 3500 Operation manual

Graco

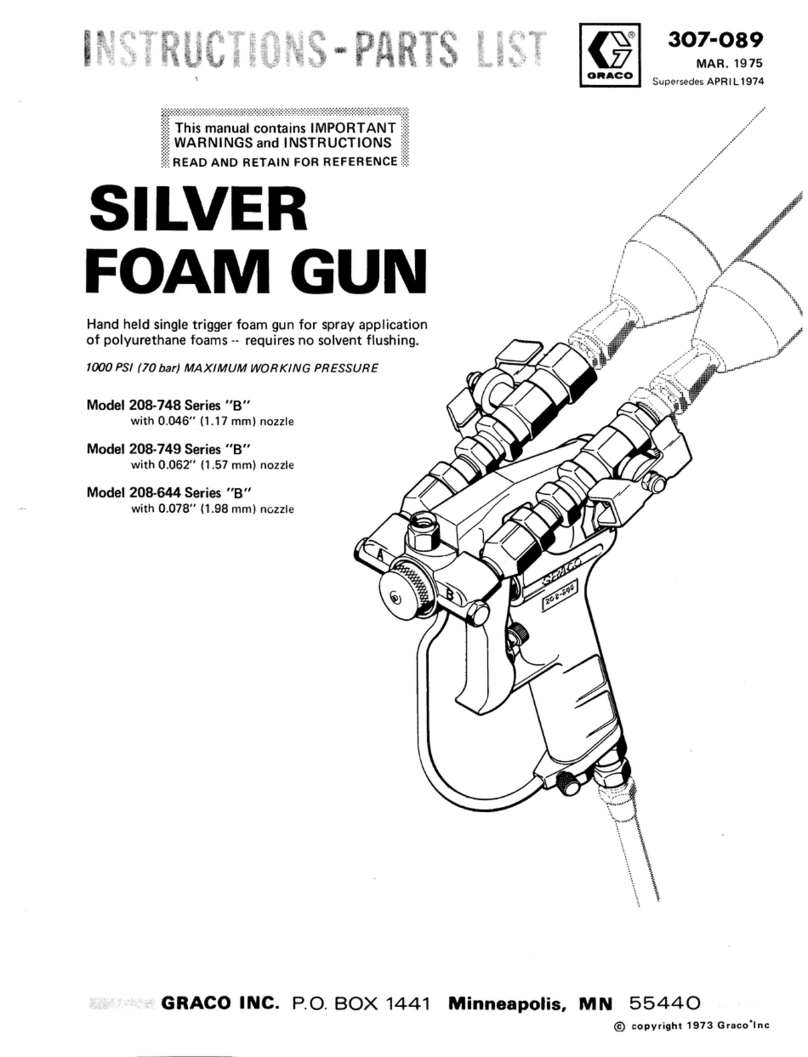

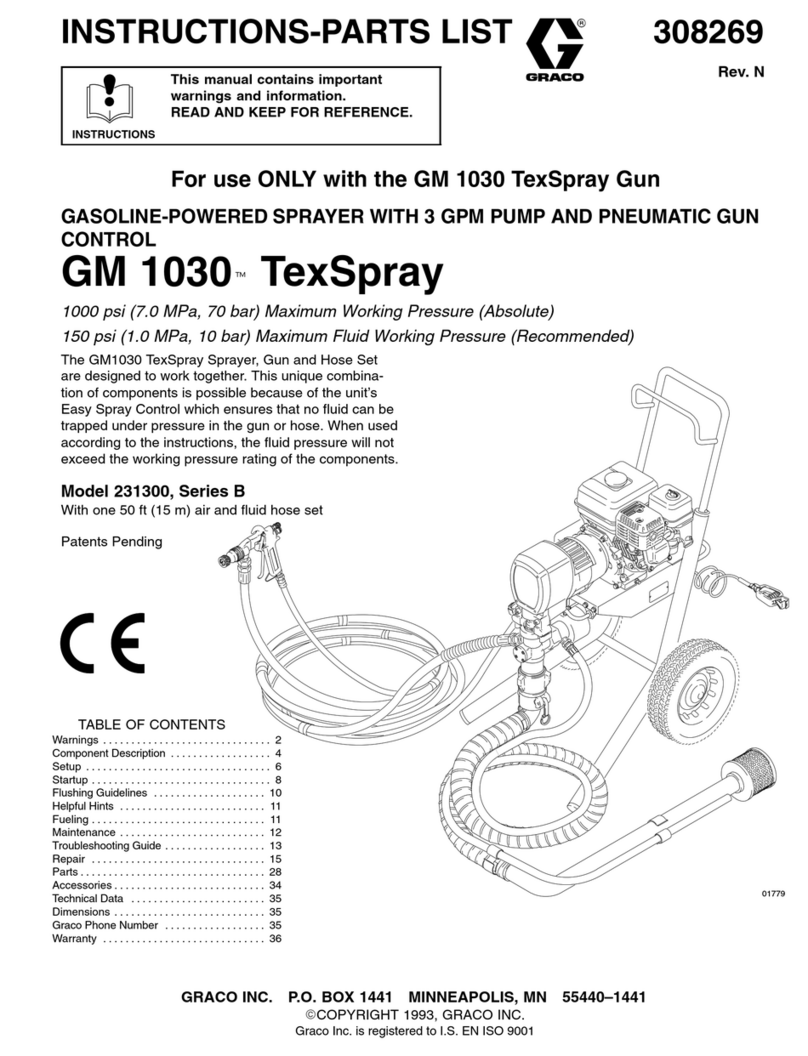

Graco Series B Operation manual

Graco

Graco C Series Guide

Graco

Graco Series A Operation manual

Graco

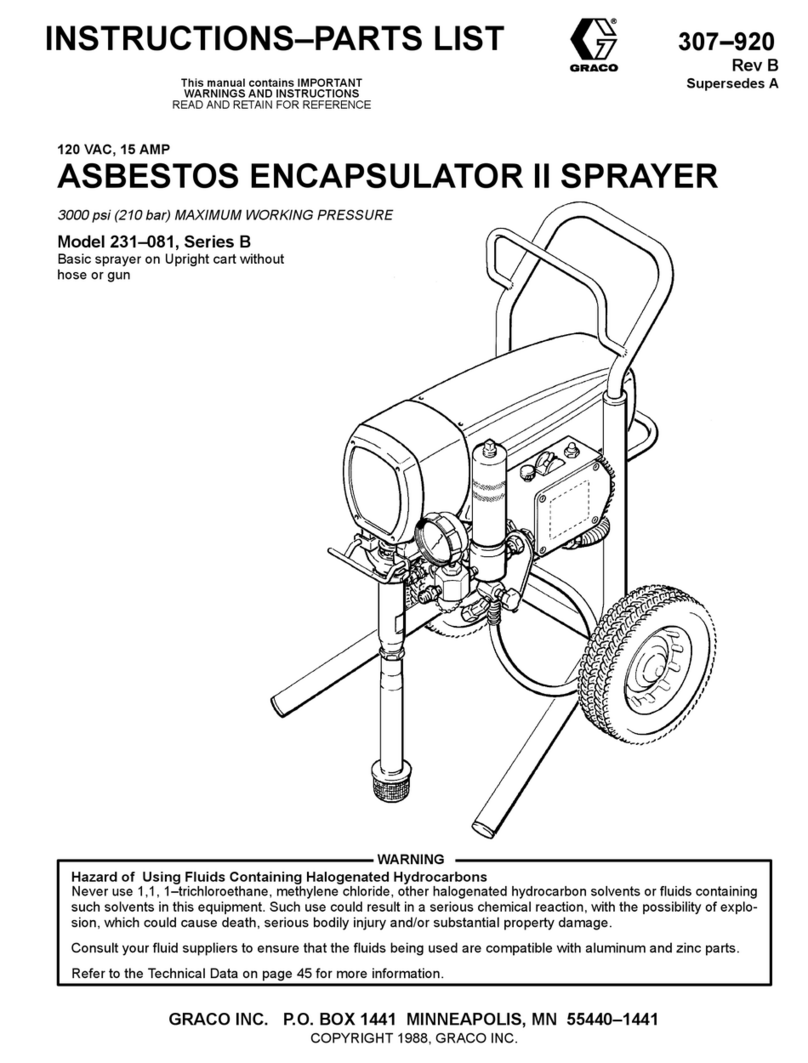

Graco 231-081 Datasheet

Graco

Graco HA1M10 Operation manual

Graco

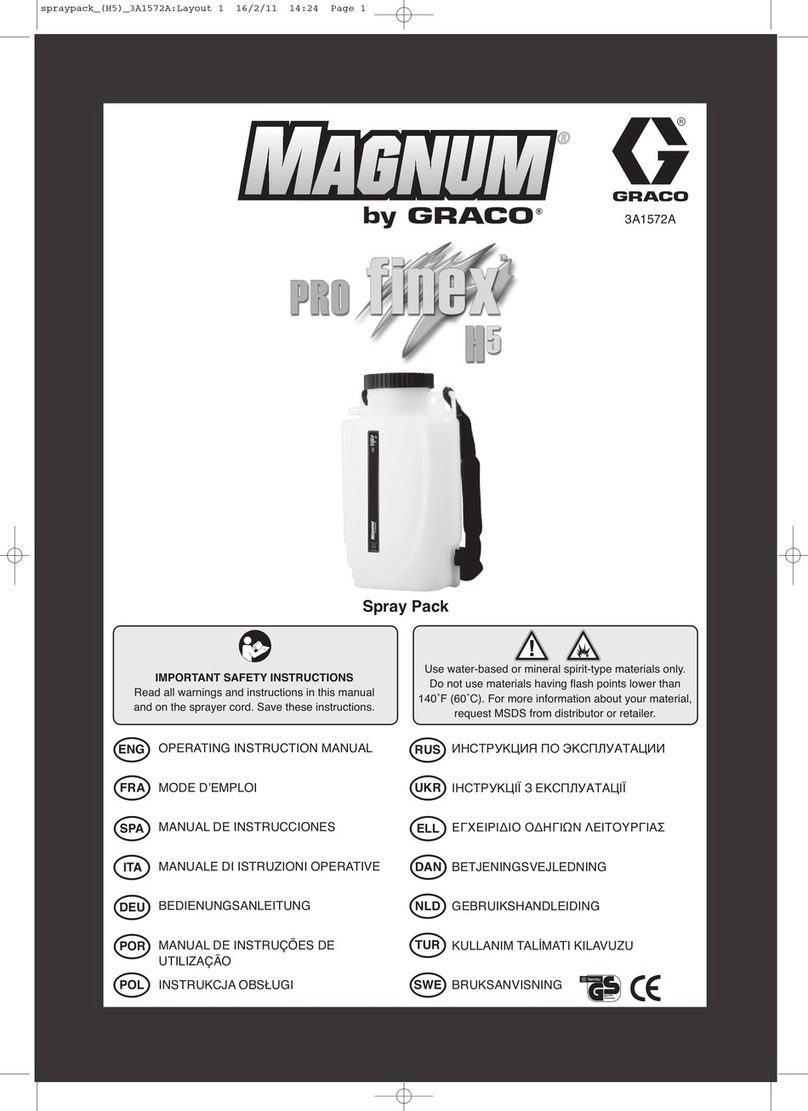

Graco Magnum XR5 User manual

Graco

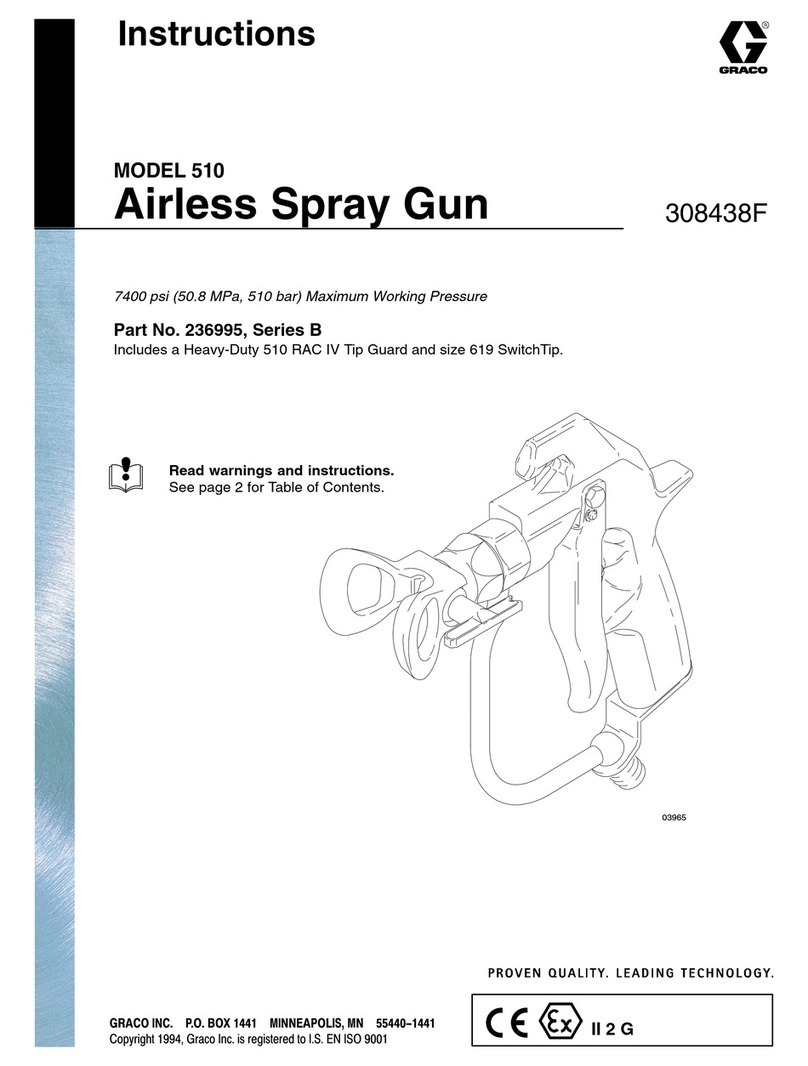

Graco 510 Manual

Graco

Graco TexSpray 248091 Guide

Graco

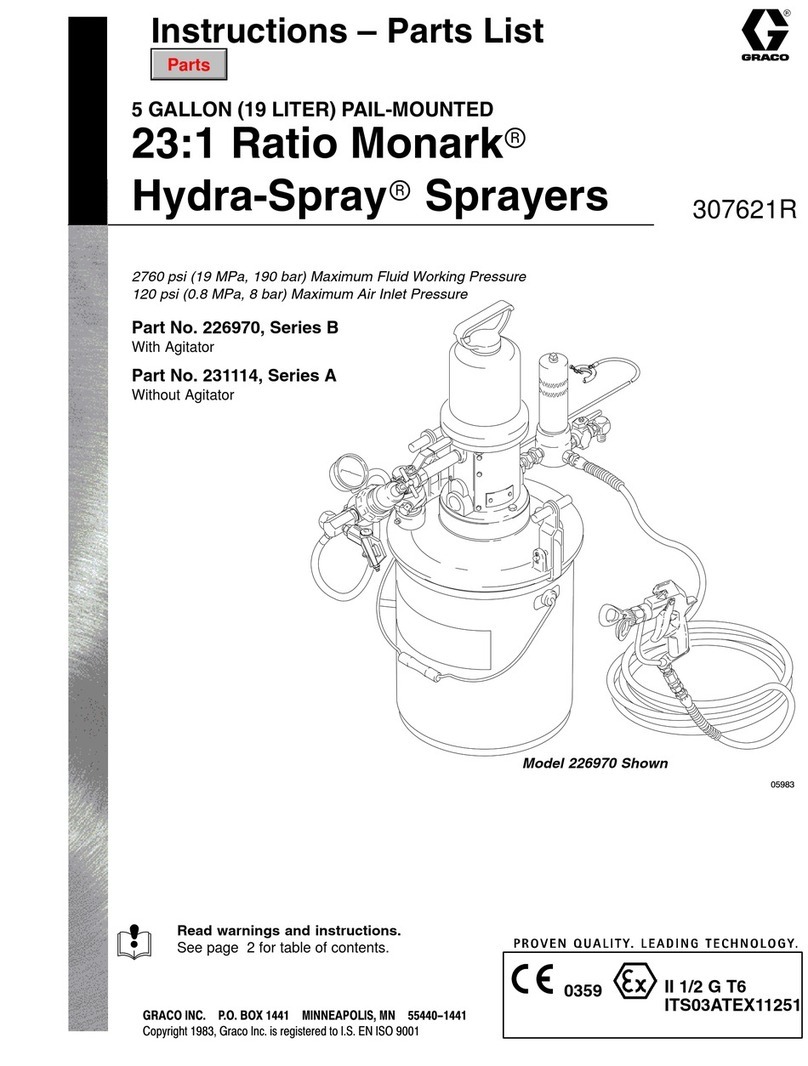

Graco Hydra-Spray B Series User manual

Graco

Graco ULTRA MAX 795 User manual

Graco

Graco DutyMax DH230 Guide

Graco

Graco 238338 Operation manual

Graco

Graco Ultra Guide

Graco

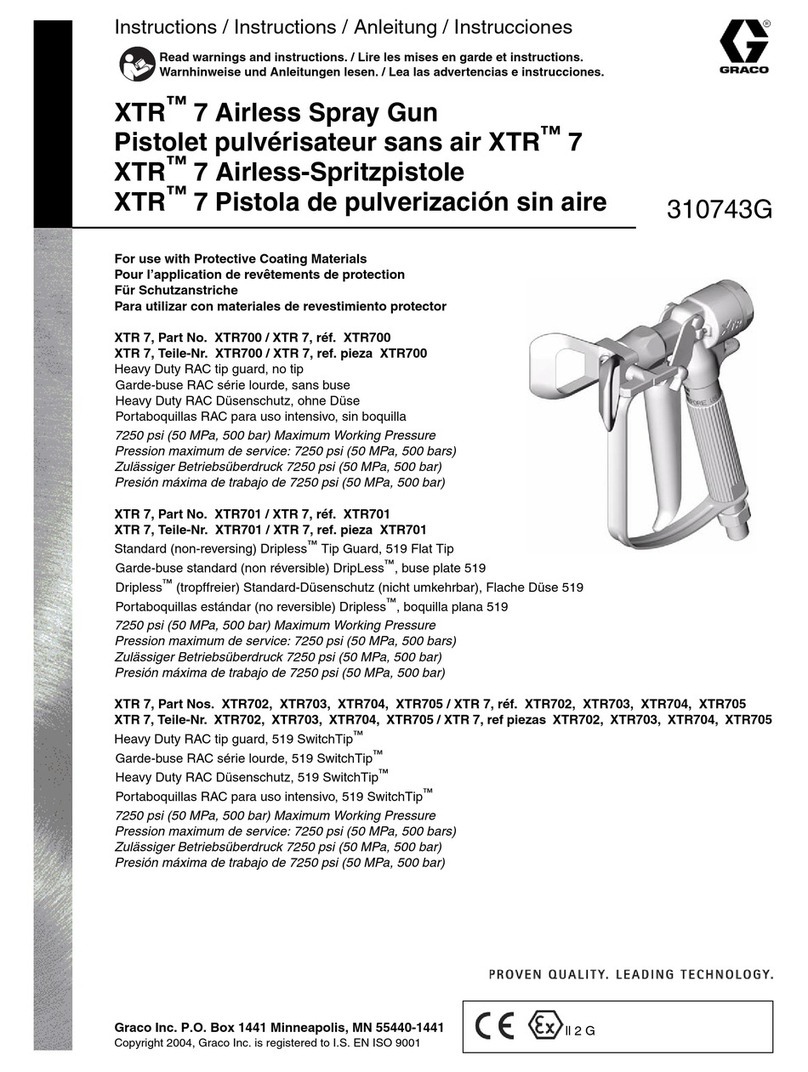

Graco XTR 310743G User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual