Contents Contents

Contents

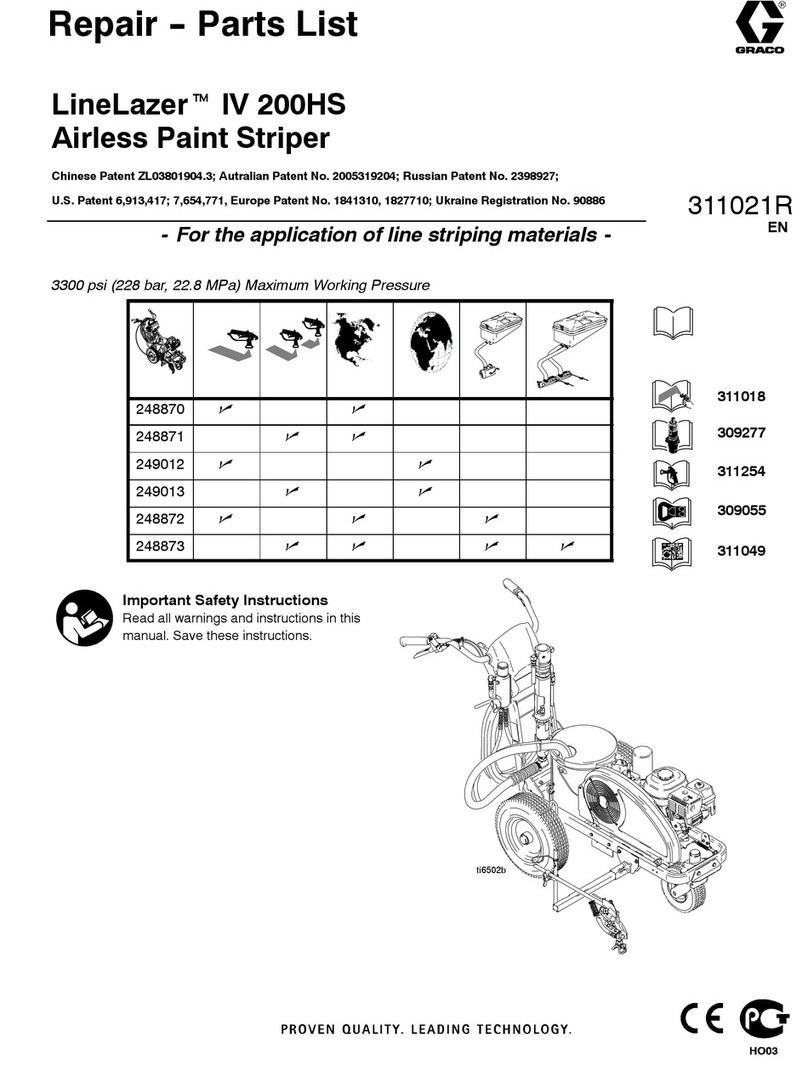

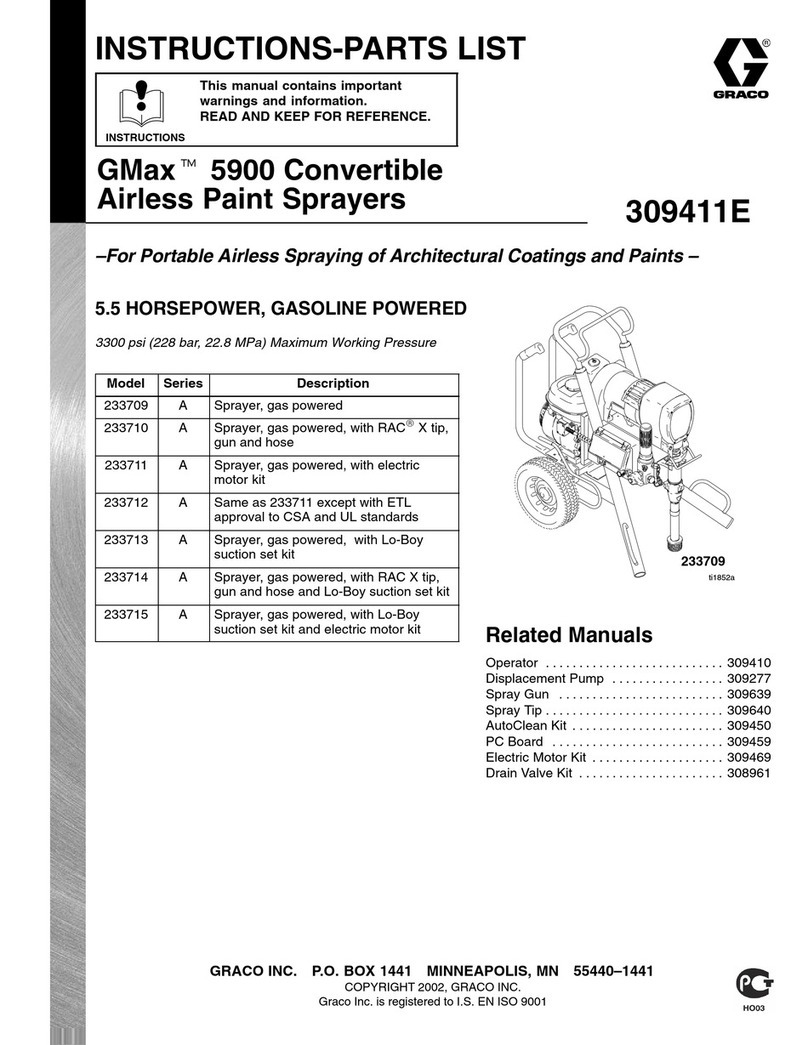

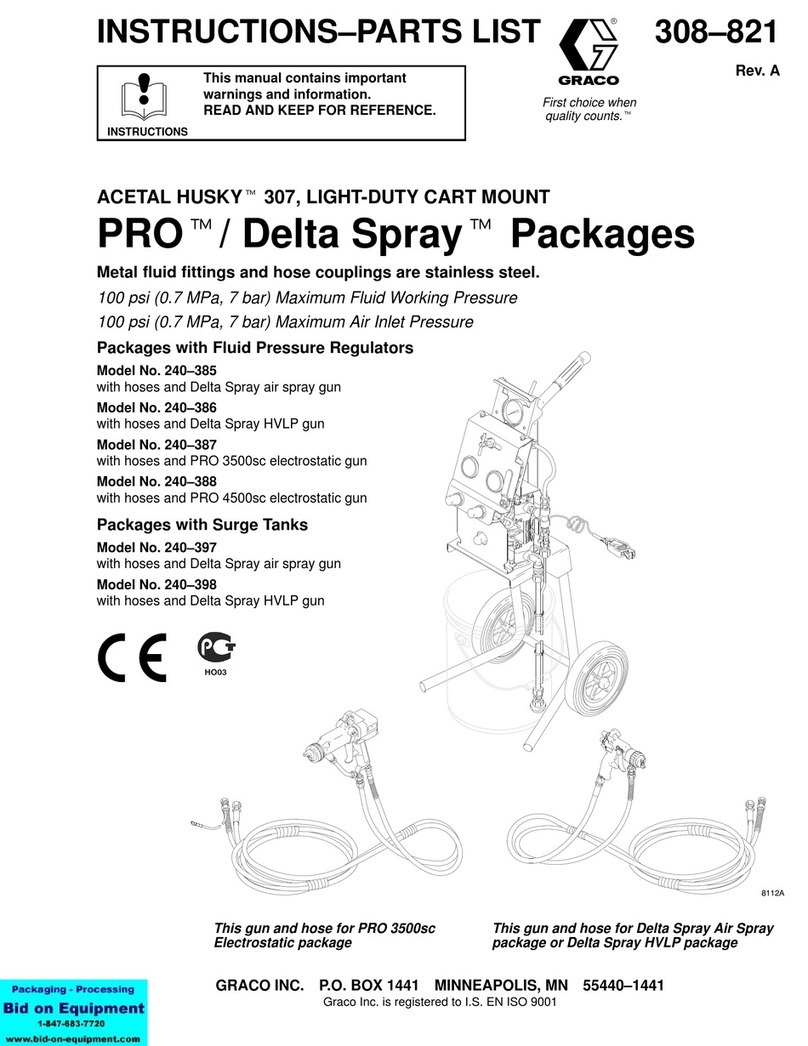

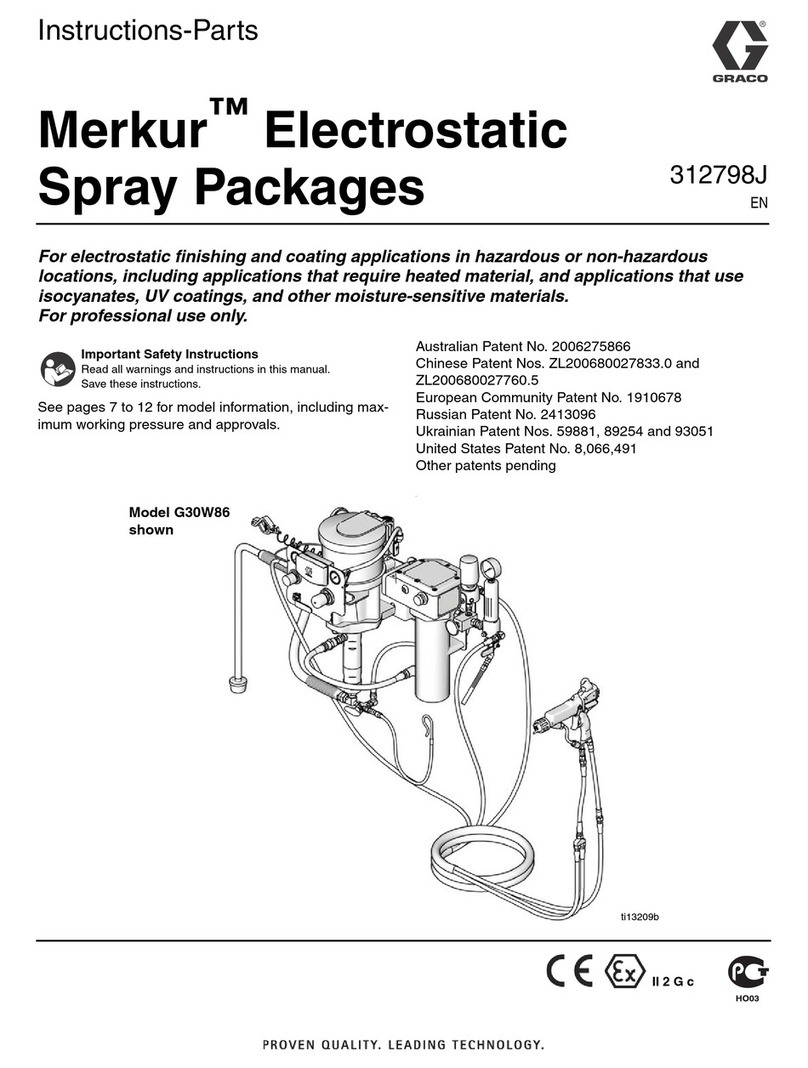

Models...............................................................3

Warnings...........................................................4

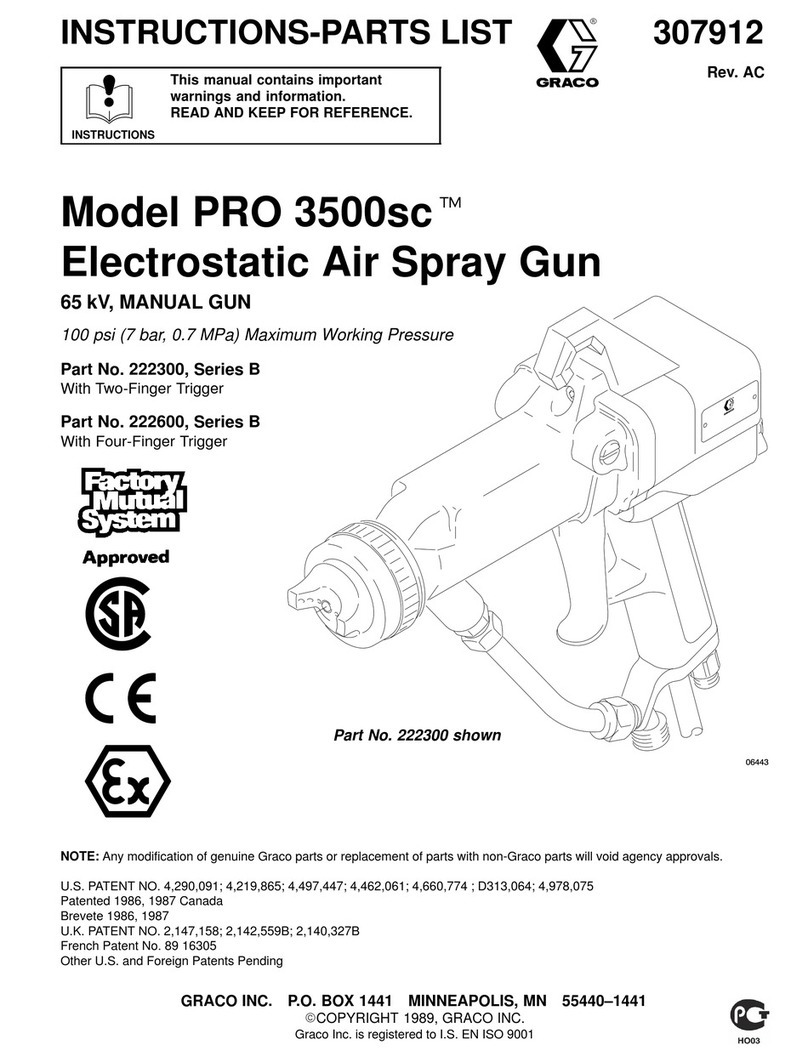

GunOverview....................................................7

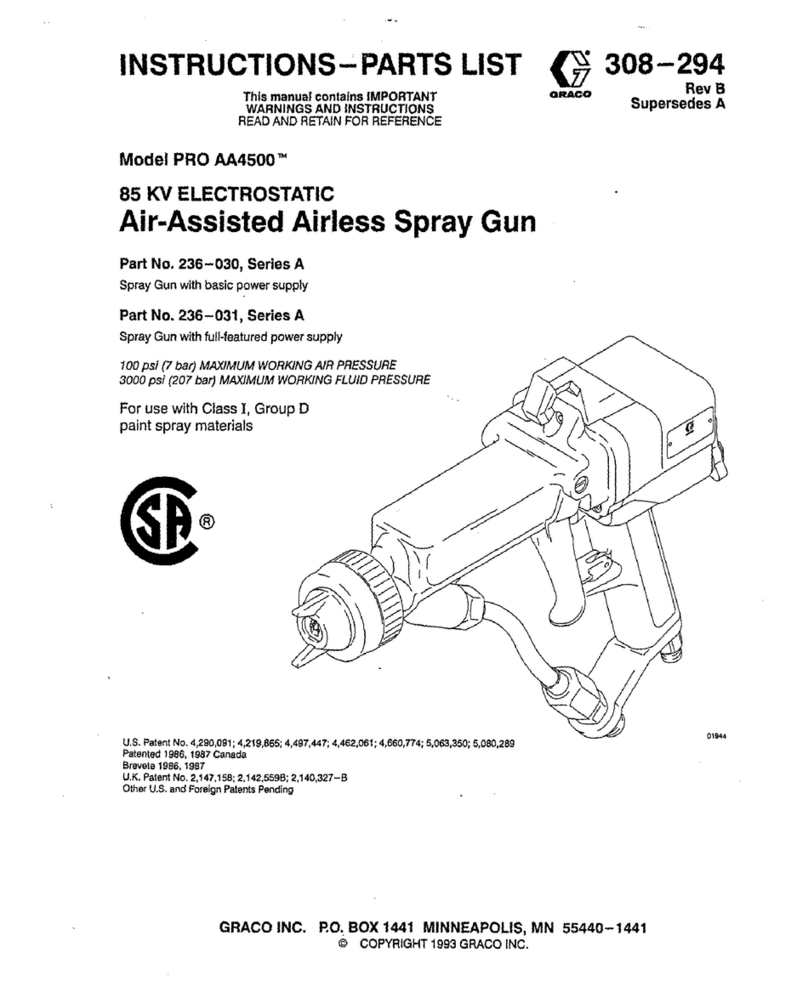

HowtheElectrostaticSprayGun

Works............................................7

Controls,Indicators,andComponents...........8

SmartGuns.................................................9

Installation..........................................................15

WarningSign...............................................15

VentilatetheSprayBooth.............................15

AirSupplyLine............................................16

FluidSupplyLine.........................................16

GunSetup..........................................................18

GunSetupChecklist....................................18

Grounding...................................................21

CheckGunElectricalGrounding...................25

CheckFluidResistivity.................................26

CheckFluidViscosity...................................26

FlushBeforeUsingEquipment......................26

GuidelinesforAbrasiveMaterials..................26

Operation...........................................................27

PressureReliefProcedure............................27

Startup........................................................27

Shutdown....................................................27

Maintenance......................................................28

Flushing......................................................28

CleantheGunDaily.....................................29

DailySystemCare.......................................30

ElectricalTests...................................................31

TestGunResistance....................................31

TestPowerSupplyResistance.....................32

TestElectrodeResistance............................32

Troubleshooting..................................................33

SprayPatternTroubleshooting......................33

GunOperationTroubleshooting....................34

ElectricalTroubleshooting............................35

Repair................................................................37

PreparetheGunforService.........................37

AirCapandNozzleReplacement..................38

ElectrodeReplacement................................39

FluidPackingRodRemoval..........................40

PackingRodRepair.....................................40

BarrelRemoval............................................42

BarrelInstallation.........................................42

PowerSupplyRemovaland

Replacement..................................43

AlternatorRemovalandReplacement...........44

FluidTubeRemovalandReplacement...........46

FanAirAdjustmentValveRepair..................47

AtomizingAirRestrictorValveRepair............48

ESOn-OffandFluidAdjustmentValve

Repair............................................49

AirValveRepair...........................................50

SmartModuleReplacement..........................51

AirSwivelandExhaustValve

Replacement..................................52

Parts..................................................................53

StandardAirSprayGunAssembly................53

RoundSprayAssembly................................55

StandardHighConductivityAirSprayGun

Assembly.......................................56

SmartHighConductivityAirSprayGun

Assembly.......................................58

SmartAirSprayGunAssembly.....................60

PackingRodAssembly.................................62

AlternatorAssembly.....................................63

ESOn-OffandFluidAdjustmentValve...........64

FanAirAdjustmentValveAssembly..............65

AtomizingAirRestrictorValve

Assembly.......................................65

SmartModuleAssembly...............................66

HighConductivityFluidTube

Assembly.......................................67

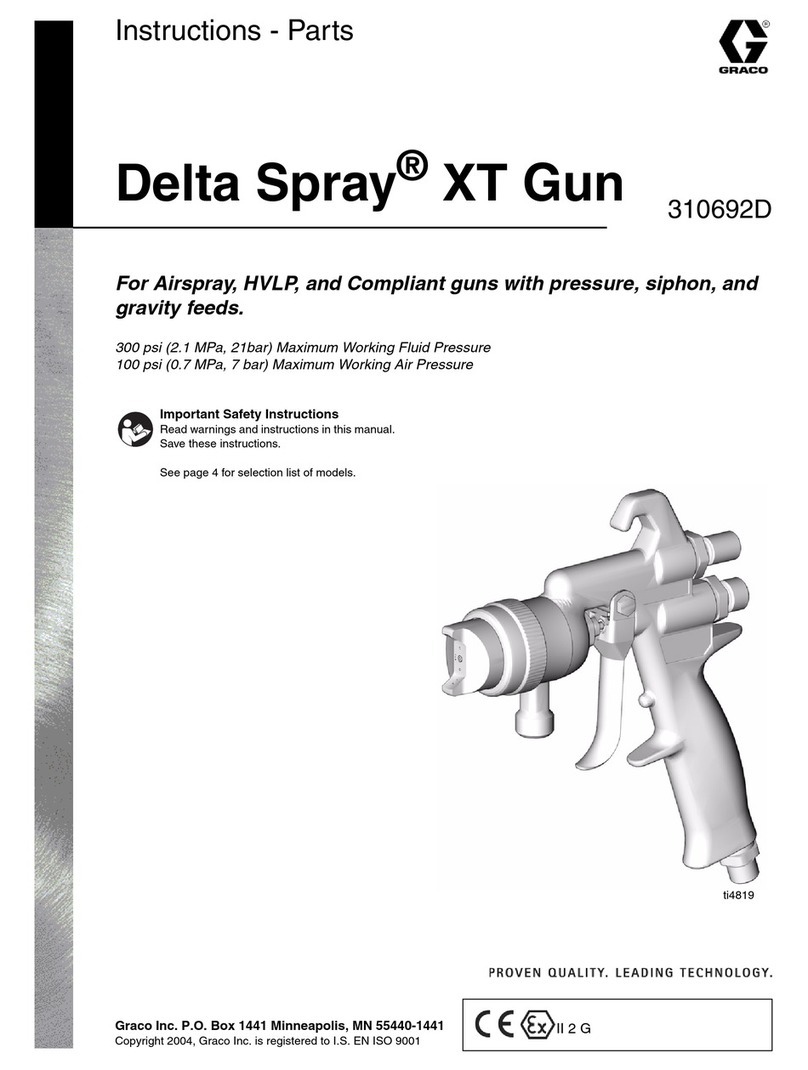

AirCapsandFluidNozzles.................................68

FluidNozzleSelectionChart.........................68

FluidNozzlePerformanceCharts..................68

AirCapSelectionChart................................70

AirConsumptionCharts...............................71

RepairKits,RelatedManuals,and

Accessories..........................................73

GunAccessories..........................................73

OperatorAccessories...................................74

SystemAccessories.....................................74

TestEquipment...........................................74

Hoses.........................................................75

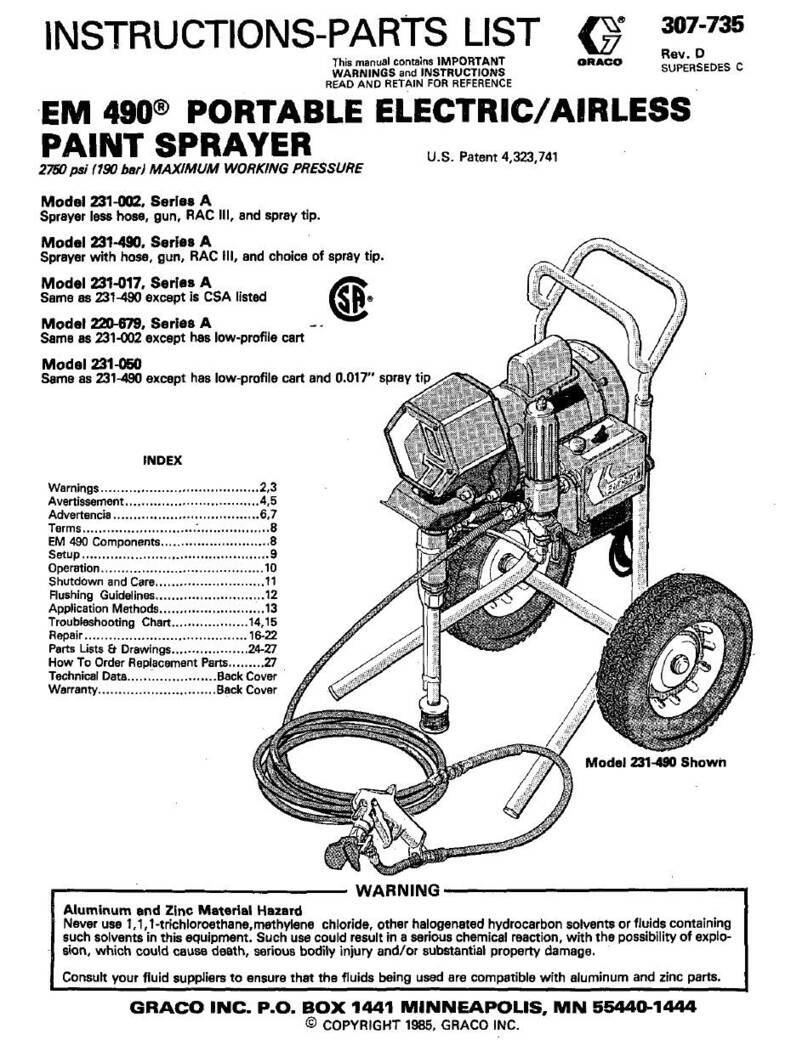

Dimensions........................................................76

TechnicalData...................................................77

GracoProXpWarranty.......................................78

2

3A2494D