Graco TexSpray Compact HP 231-801 Operation manual

Other Graco Paint Sprayer manuals

Graco

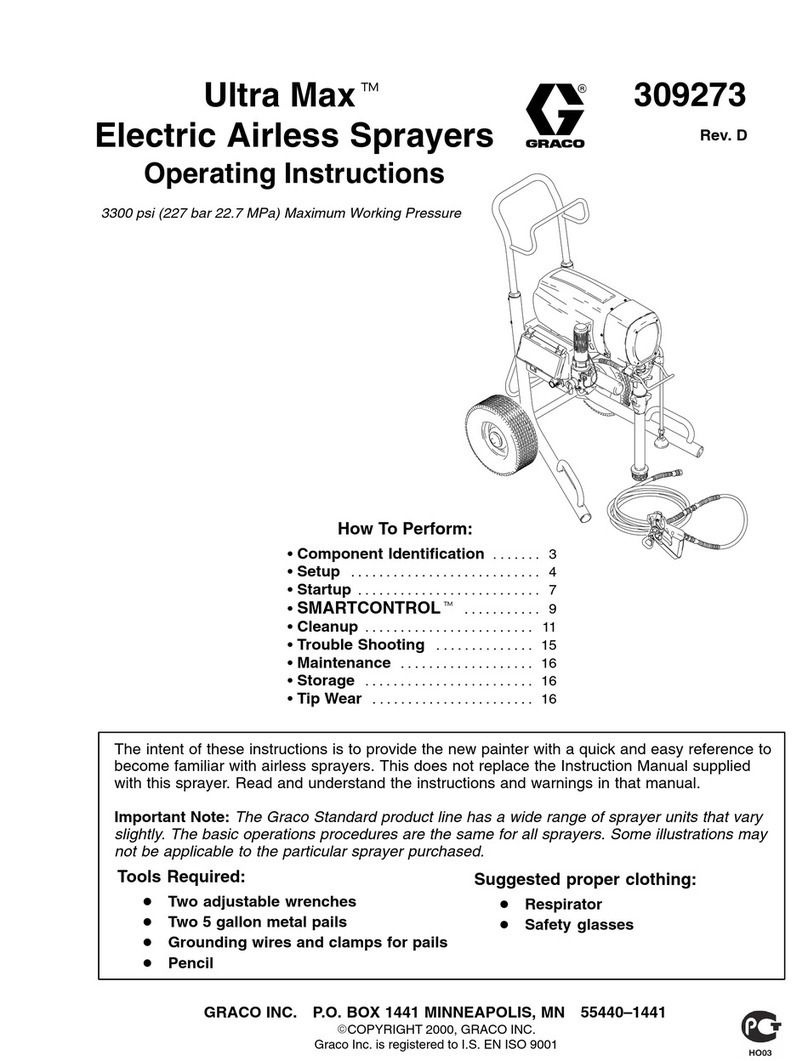

Graco Ultra Max 309273 User manual

Graco

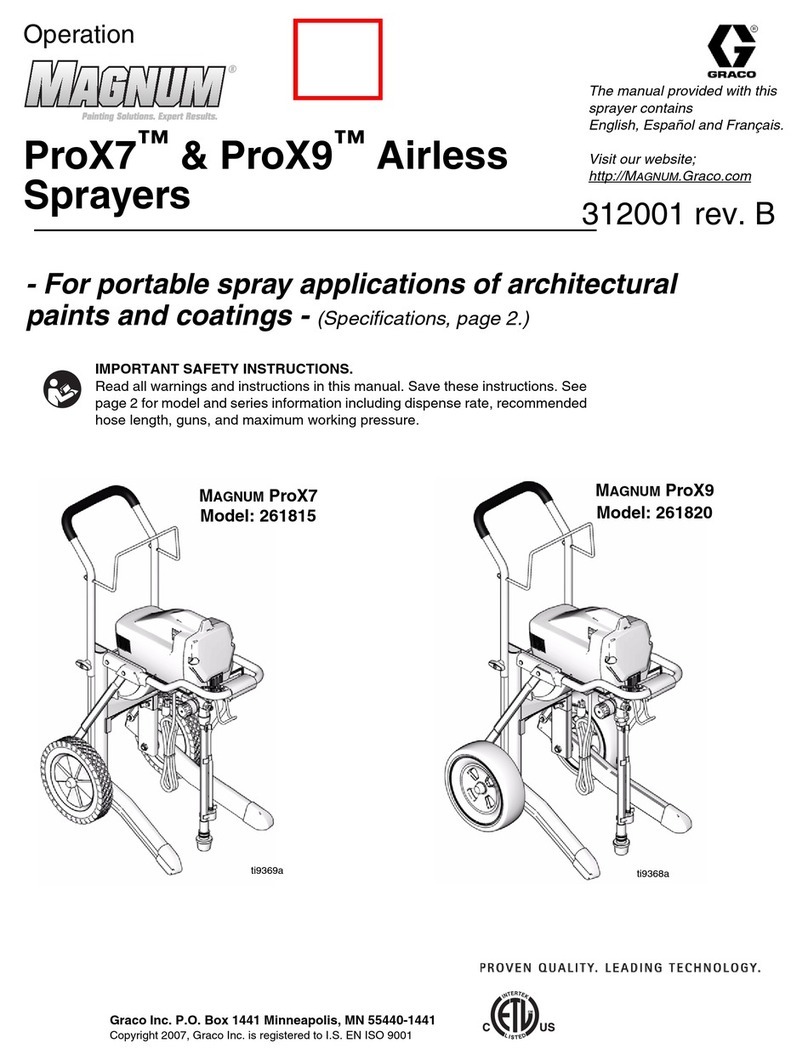

Graco Magnum ProX7 Instruction Manual

Graco

Graco RentalPro 230PC HDR User manual

Graco

Graco 309489 User manual

Graco

Graco Nova 312858B User manual

Graco

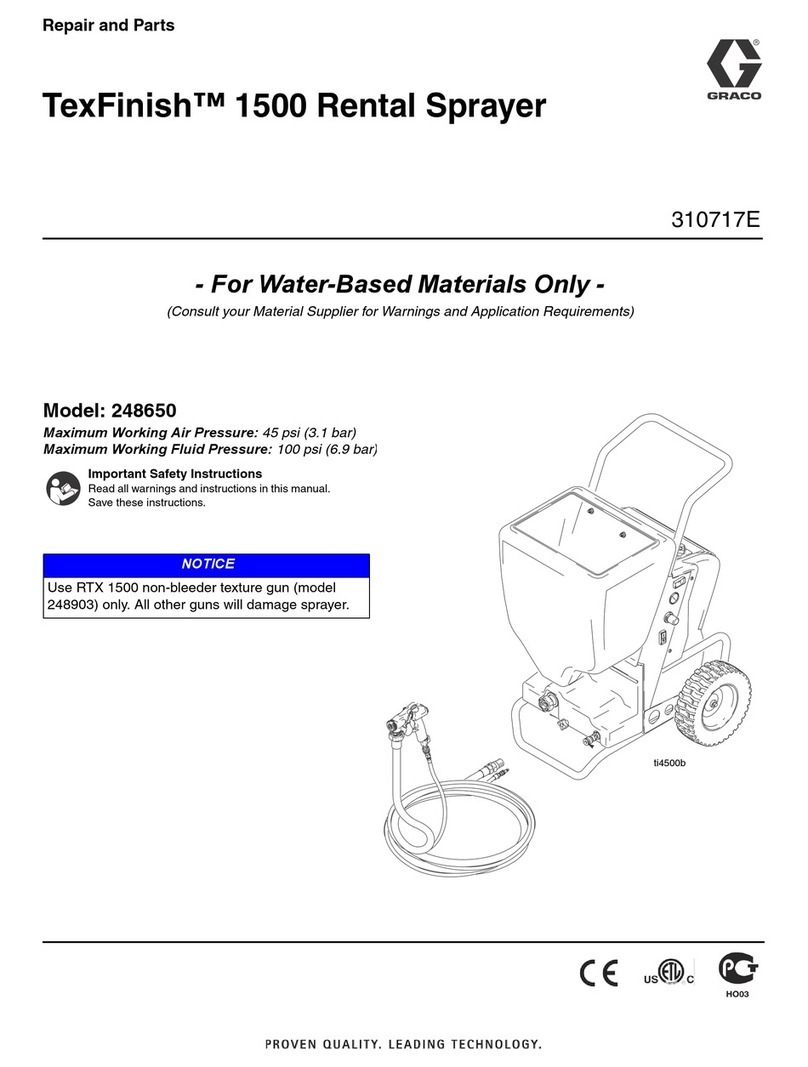

Graco RTX 1500 Guide

Graco

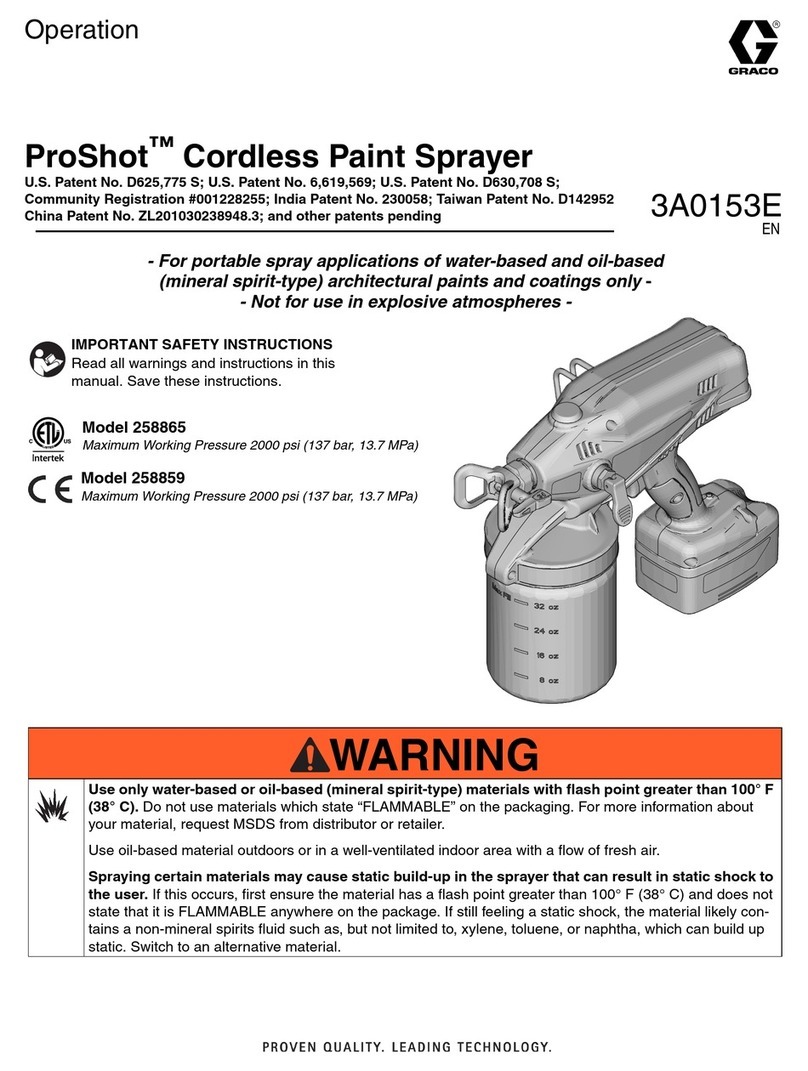

Graco ProShot 258865 User manual

Graco

Graco Project Painter Plus User manual

Graco

Graco Glascraft Formula-X User manual

Graco

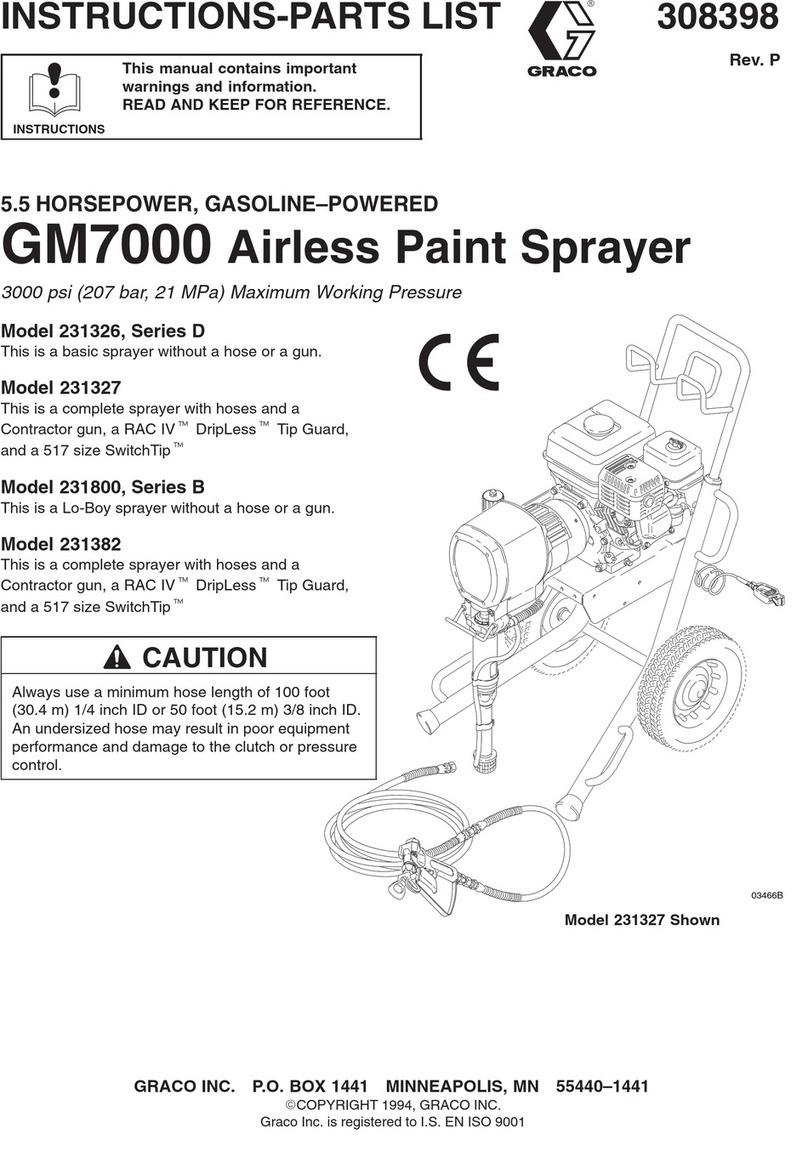

Graco GM7000 231327 Operation manual

Graco

Graco GMAX 3400 Instruction Manual

Graco

Graco EH 333 HYDRA-SPRAY A Series Operation manual

Graco

Graco UNICARB Pro AA4500 User manual

Graco

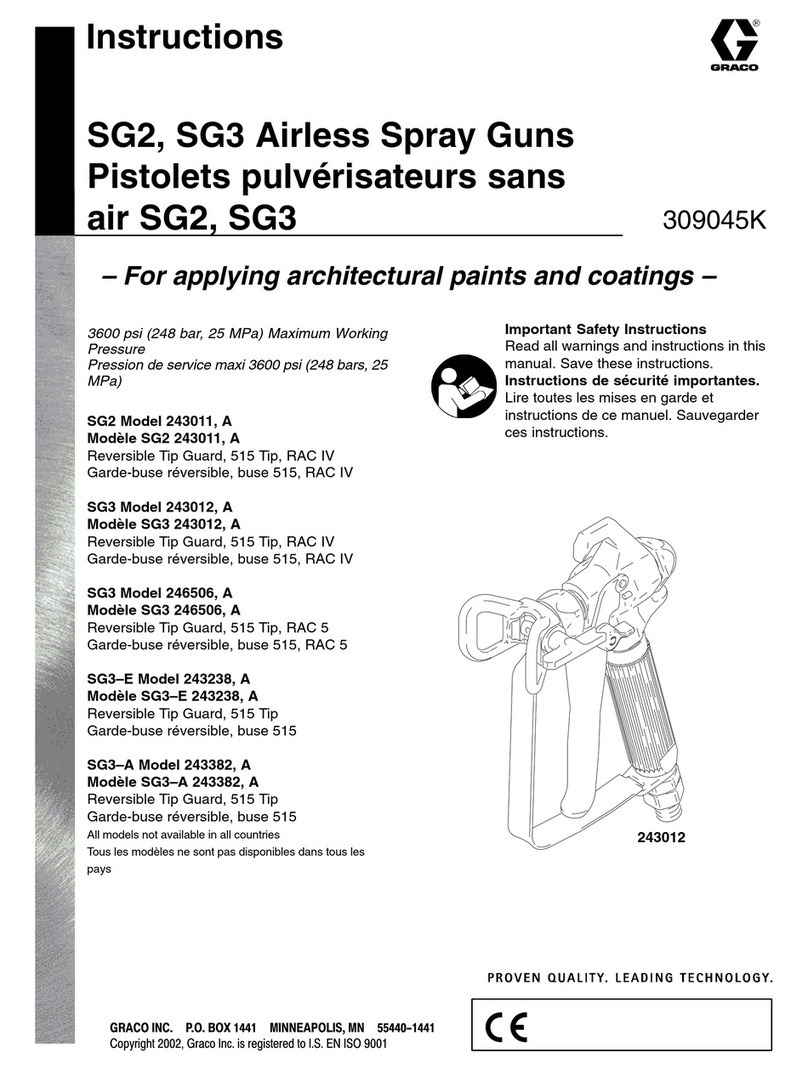

Graco Magnum 309045K User manual

Graco

Graco Finishpro 390 Instruction Manual

Graco

Graco e-Xtreme Z60 User manual

Graco

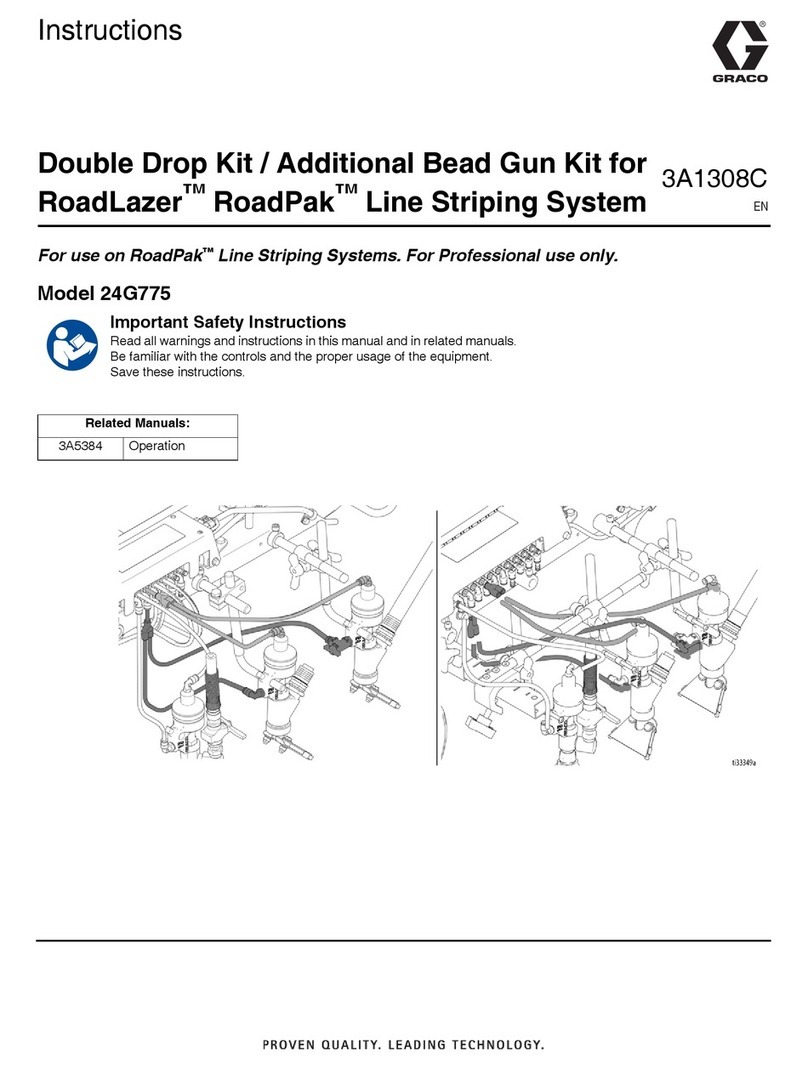

Graco 24G775 User manual

Graco

Graco PRO Xs Parts list manual

Graco

Graco 24H685 Troubleshooting guide

Graco

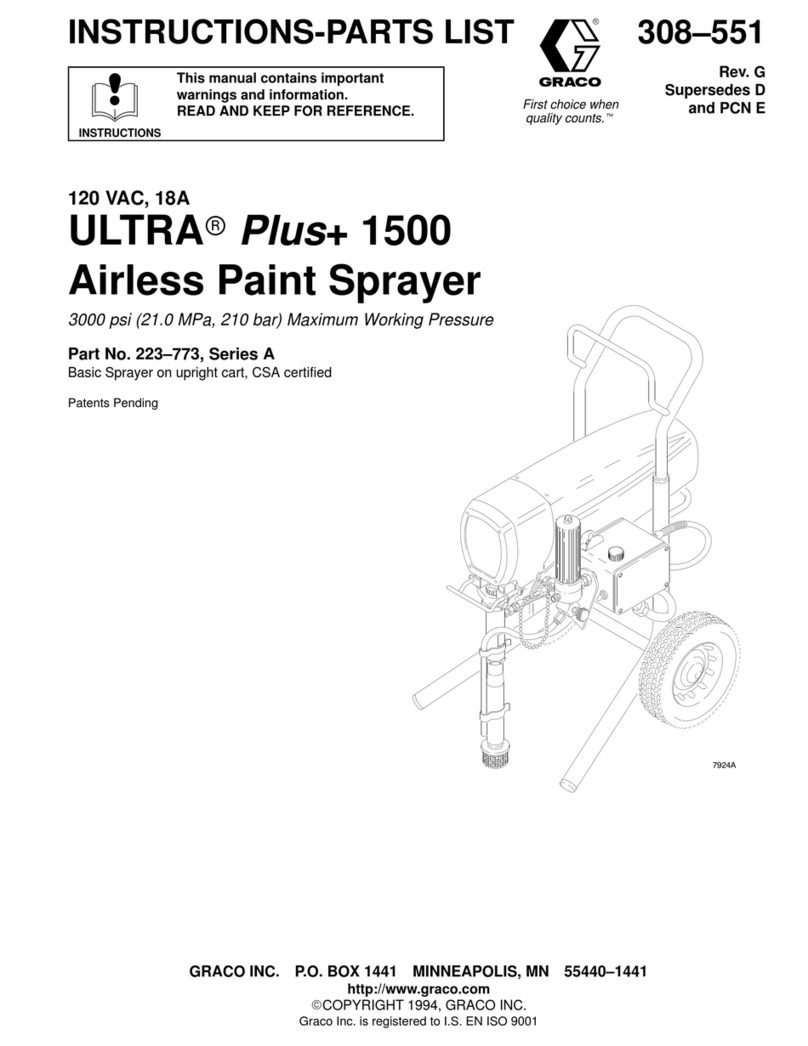

Graco 223-773 A Series Datasheet

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual