3/24

GrainPro® Cocoon™ Cargo Instruction Manual

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................................................ 4

2. CHECKLIST................................................................................................................................................. 5

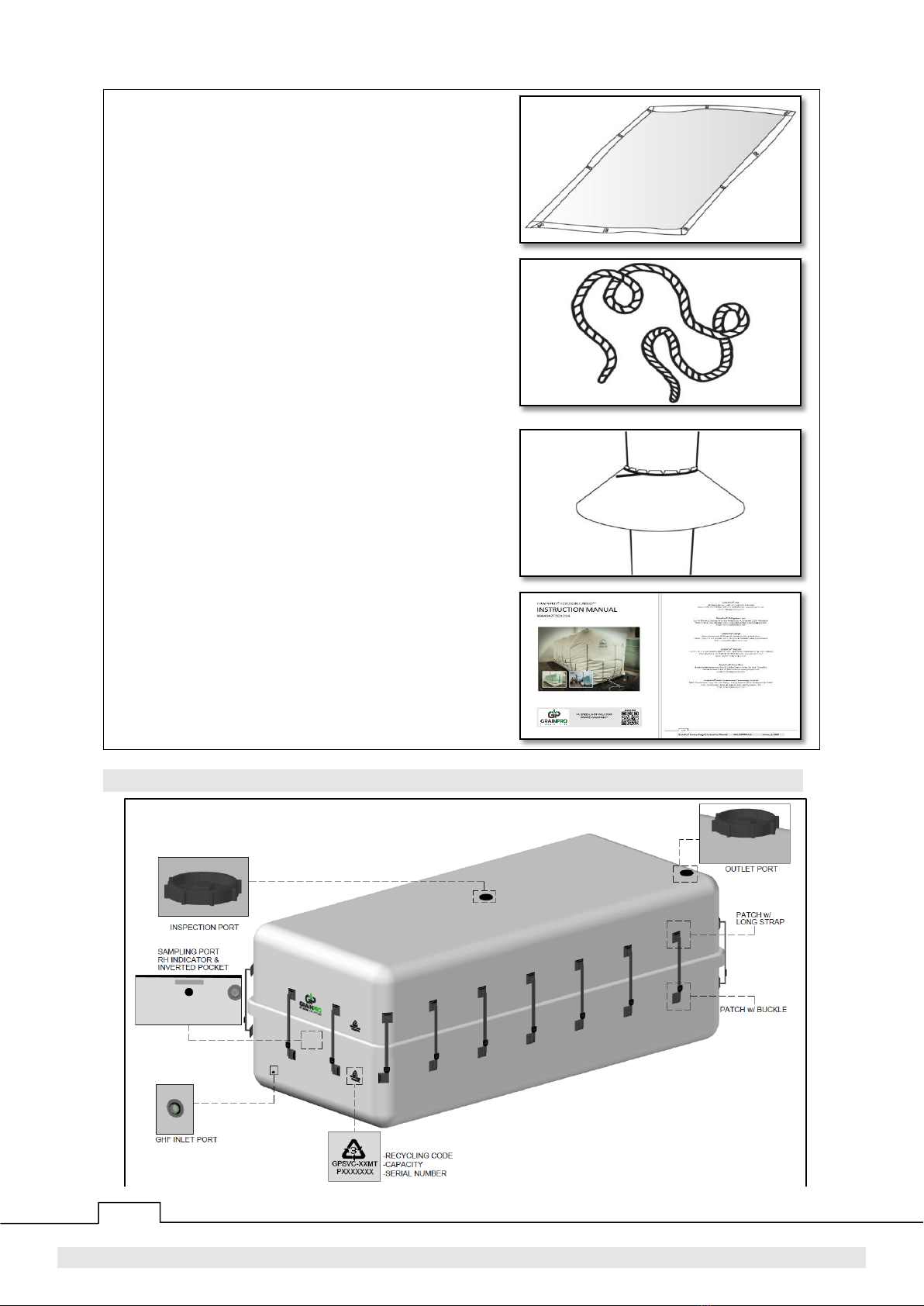

3. COMPONENTS .......................................................................................................................................... 6

4. SPECIFICATIONS........................................................................................................................................ 7

5. INSTALLATION .......................................................................................................................................... 7

Site selection....................................................................................................................................... 7

Loading ............................................................................................................................................... 7

Positioning the top section................................................................................................................. 8

Use of Desiccant (Calcium Chloride, CaCl2) –(Recommended).......................................................... 9

Zipping ................................................................................................................................................ 9

Pressure (vacuum) decay test........................................................................................................... 11

Tensioning of straps (protecting zipper)........................................................................................... 12

Carbon dioxide (CO2) safety.............................................................................................................. 12

Procedure for purging with carbon dioxide...................................................................................... 13

Using oxygen analyzer for monitoring.............................................................................................. 15

Using carbon dioxide analyzer for monitoring ................................................................................. 16

Monitoring relative humidity (%RH)................................................................................................. 17

Using GrainPro EcoWiSe for wireless monitoring............................................................................. 17

Dismantling ...................................................................................................................................... 18

6. PREVENTING CONDENSATION ............................................................................................................... 18

Why condensation occurs ................................................................................................................ 18

Moisture content (MC) requirement for safe storage...................................................................... 18

Setting-up the GrainShade (Outdoor installation)............................................................................ 19

7. MAINTENANCE AND CARE ..................................................................................................................... 19

Regular examination......................................................................................................................... 19

Physical inspection ........................................................................................................................... 19

Repairing punctures and other damages ......................................................................................... 20

Prohibited items for air shipment .................................................................................................... 20

Cleaning top and bottom sections.................................................................................................... 20

Folding .............................................................................................................................................. 21

Safekeeping ...................................................................................................................................... 21

Platform installation of rodent guard............................................................................................... 21

Termite control................................................................................................................................. 22

Recycling........................................................................................................................................... 23

8. FREQUENTLY ASKED QUESTIONS ........................................................................................................... 23

9. WARRANTY CLAUSE................................................................................................................................ 24