765042420 Rev.000 2

Table of contents

Application ..................................................................................................................................................... 3

Safety information .......................................................................................................................................... 4

Location ......................................................................................................................................................... 5

Optimizing the energy consumption .............................................................................................................. 7

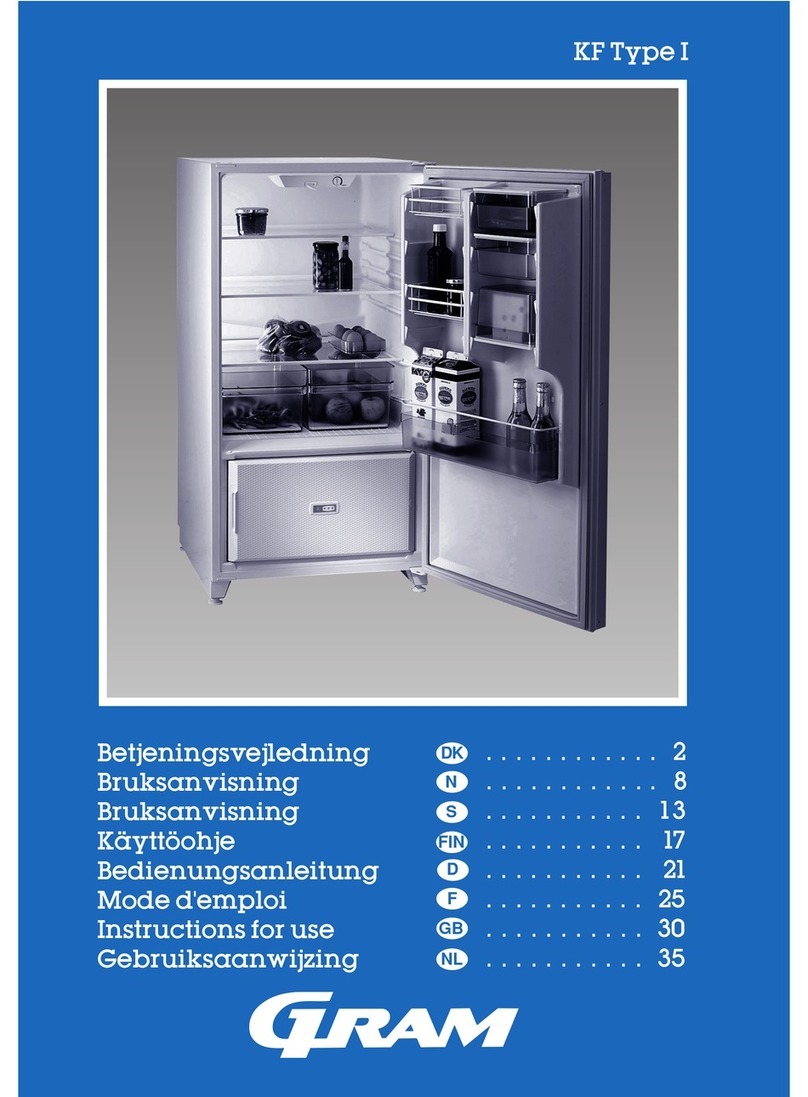

General description ....................................................................................................................................... 8

Refrigerant / GWP value ............................................................................................................................... 9

Climate / temperature class ........................................................................................................................... 9

Electrical connection ...................................................................................................................................... 9

General use ................................................................................................................................................. 11

Operating the product .................................................................................................................................. 13

Keyboard lock .............................................................................................................................................. 14

Changing the temperature ........................................................................................................................... 15

Errors and Alarms ........................................................................................................................................ 15

Display of the evaporator sensor reading ................................................................................................... 16

HACCP Alarms ............................................................................................................................................ 17

Setting of HACCP alarm values .................................................................................................................. 17

Display of HACCP alarms ........................................................................................................................... 17

Deletion of HACCP alarms .......................................................................................................................... 18

Cleaning of condenser filter ......................................................................................................................... 19

Defrosting .................................................................................................................................................... 19

Defrost water ............................................................................................................................................... 20

Door closing mechanism ............................................................................................................................. 21

Power failure ................................................................................................................................................ 21

Cleaning ...................................................................................................................................................... 21

Door gaskets ............................................................................................................................................... 22

Long term storage ....................................................................................................................................... 22

Service ......................................................................................................................................................... 23

Disposal ....................................................................................................................................................... 24

EC-Declaration of conformity ...................................................................................................................... 25

RoHS 3 - (EU) 2015/863 ............................................................................................................................. 25

Default factory settings ................................................................................................................................ 26

Access to service parameters ..................................................................................................................... 26

Parameter overview ..................................................................................................................................... 27

Wiring diagram K/M 139 .............................................................................................................................. 37

Wiring diagram F 139 .................................................................................................................................. 38

Piping diagram ............................................................................................................................................. 39