765042364 Rev.000 4

Make sure the appliance is switched off at the socket before service is performed on electrical

parts. It is not sufficient to switch off the cabinet by the START/STOP key as there will still be

volta

e to some electrical parts of the cabinet..

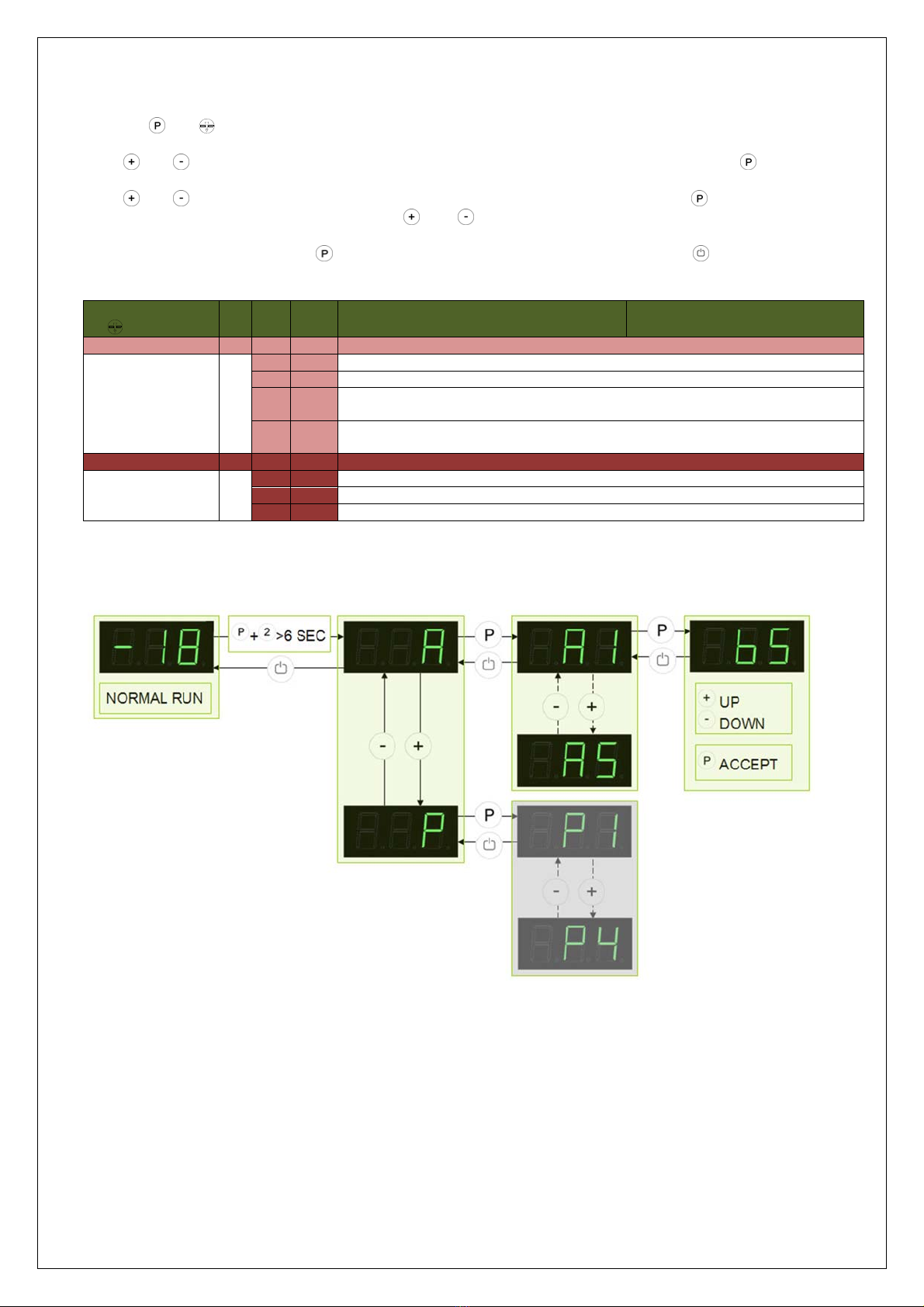

Software version and program variant in start-up sequence

When the cabinet switches ON, the controller shows the software version and program variant.

The version number glows in 2 sec. followed by name on the program variant until the controller is finished with the

start-up sequence. The program variant is like the example here below.

In the example above software ver. 2.1 and program variant M2+ is presented.

Cabinets with compressor (HAV) is given by the symbol ” ”. The

symbol should look like a “+” which means including compressor.

Cabinets without compressor (FAV) is given by the symbol ” ”.

The “-“ symbol means “Compressor not included”.

Because program variants like K and M

is difficult to present in a 7-segment

display, the symbols below is used

instead:

H (Refrigerator).

n (Extended temperature range).

P (Process cabinets).

Other program variants name:

F (freeze).

B (Counter).

V (Varm/hot/swallow cabinets)*.

E (Extreme low temperature).

* Complete new variant

Error codes in the display during normal operation

- 0 - The door is open. The alarm system is activated, if the door is not closed within a certain time.

The user is reminded that the door is not properly closed.

F1 Cabinet sensor error. In the meantime the cabinet itself will maintain the set temperature by

the memory of the controller. Service assistance is required.

F2 Evaporator sensor error.

The cabinet will keep running until the error has been mended.

Service assistance is required.

F3/F4 Condenser sensor error. The cabinet will keep running, until the error has been mended.

Service assistance is required.

Applies only to cabinets with built-in compressor.

F5 Error on the sensor for temperature controlled chilling. It has no influence on other

programmes, but it should be replaced. Service assistance is required.

F7 Indicates that the condenser temperature is too high. The cause might be a clogged

condenser, or too high ambient temperature.

If the condenser or air filter needs cleaning, the cabinet must be disconnected at the mains

power. Cleaning of the condenser is done with a brush or a vacuum cleaner.

The air filter can be removed and cleaned in a dishwasher at max. 50C.

If the ambient temperature is too high, the placement of the cabinet might be wrong, and an

alternative place should be found. Ventilation might help.

If this does not help, request service assistance.

pplies onl

to cabinets with built-in compressor.