CONTENTS

PRODUCT ....................................................................................................................2

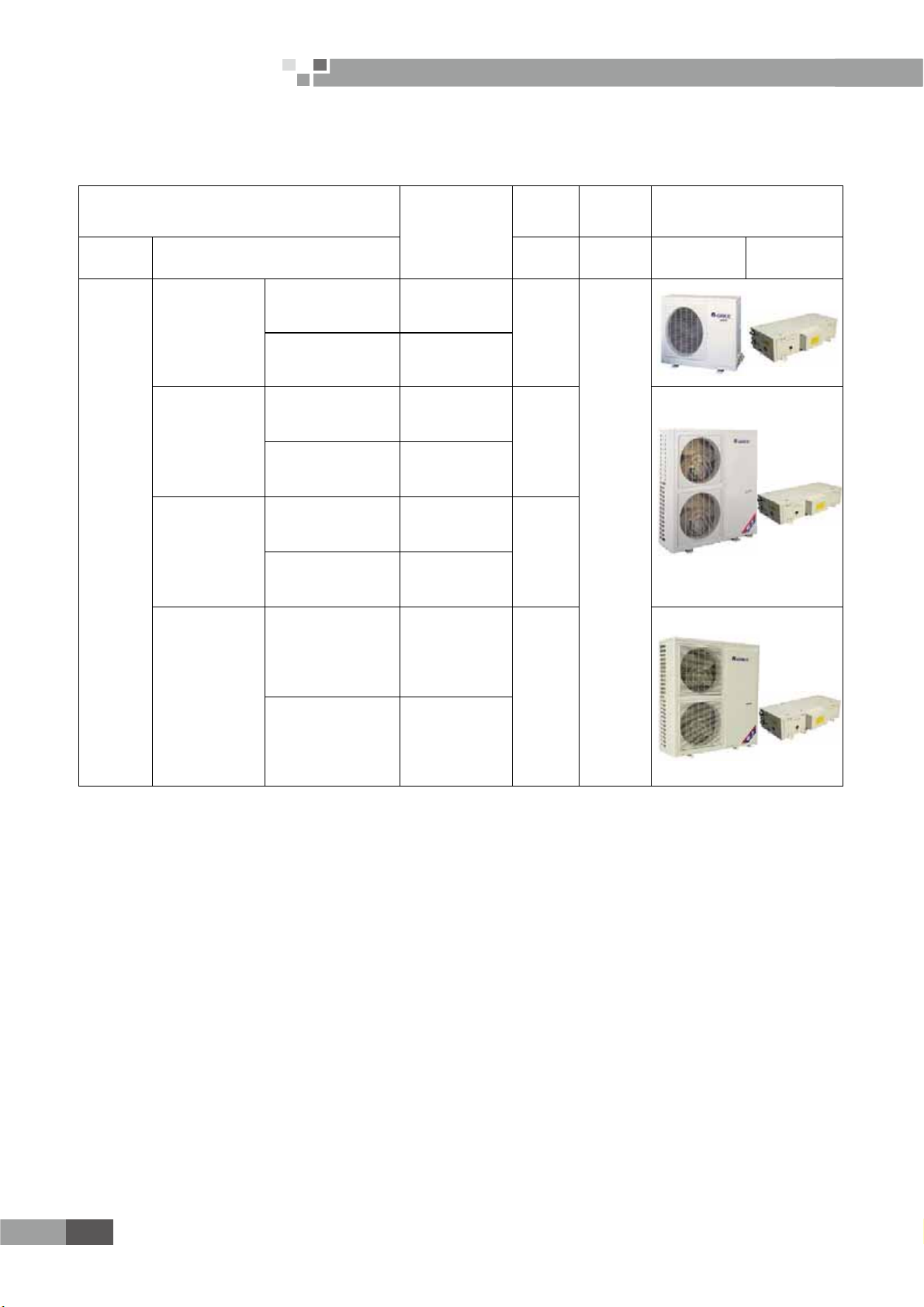

1 MODELS LIST ..........................................................................................................................2

1.1 Split Type...........................................................................................................................................................2

1.2 Integral Type.....................................................................................................................................................3

2 NOMENCLATURE....................................................................................................................3

1.1 Split Type...........................................................................................................................................................3

1.2 Integral Type.....................................................................................................................................................4

3 FUNCTION.................................................................................................................................4

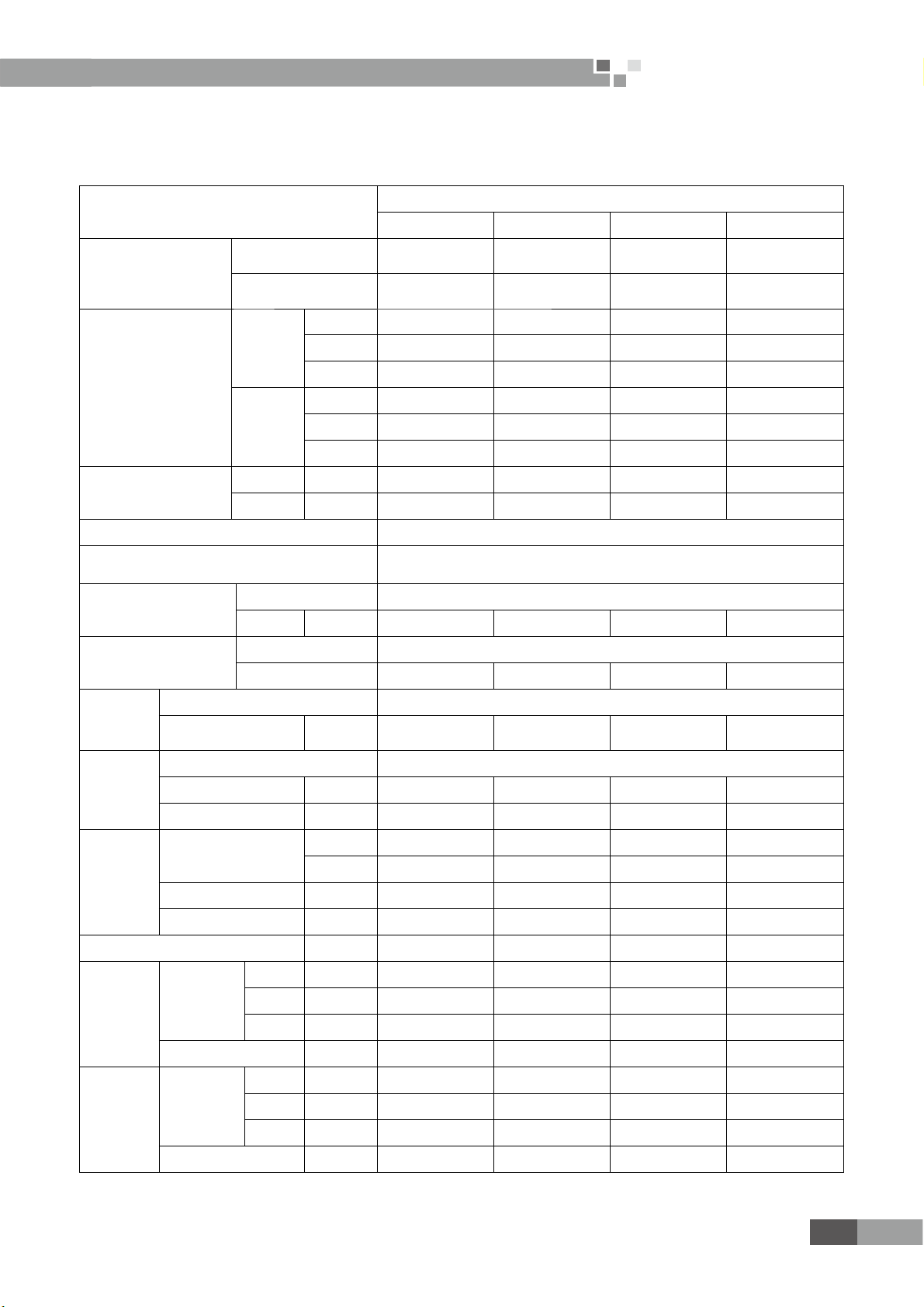

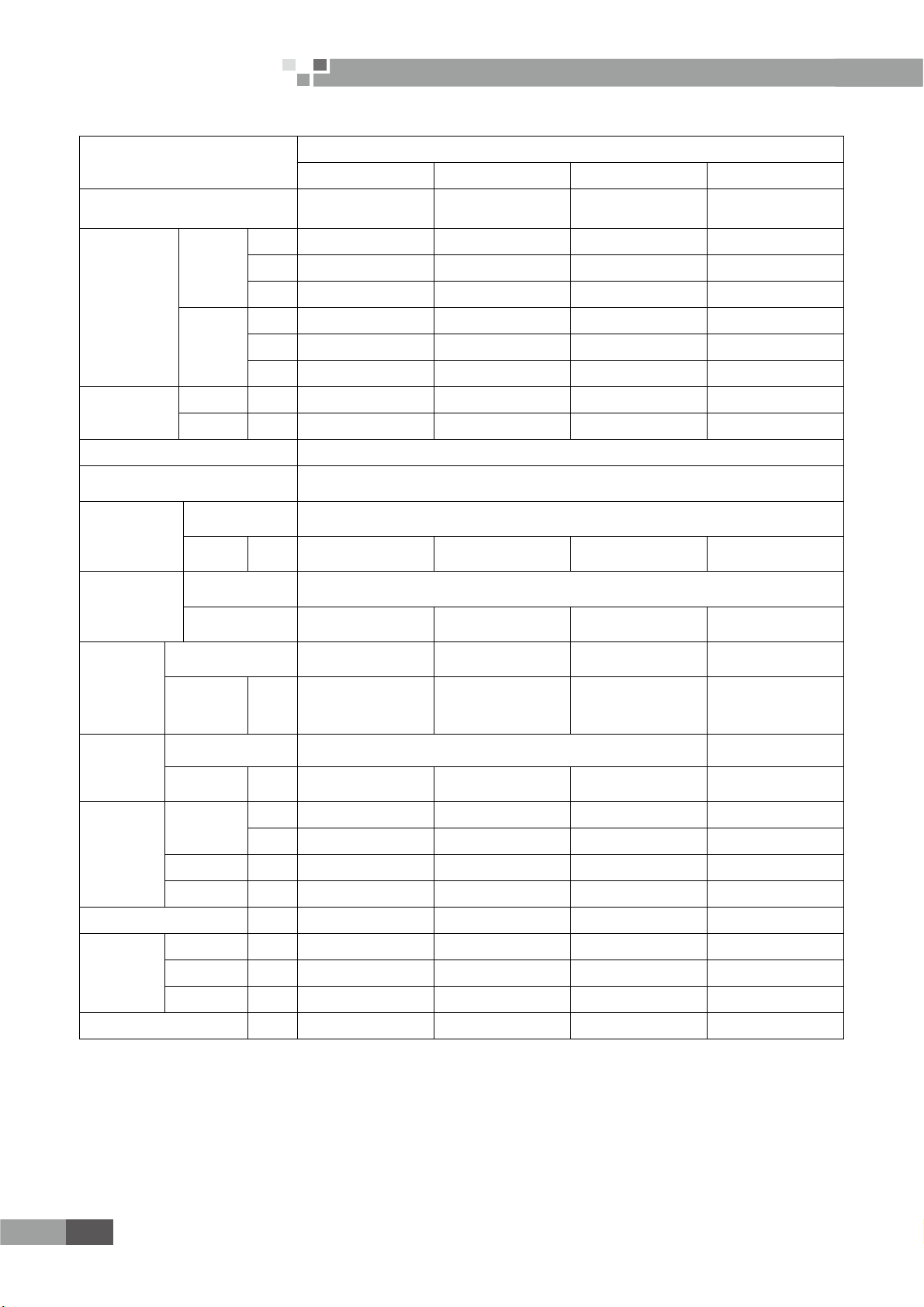

4 PRODUCT DATA.......................................................................................................................5

4.1 Product Data at Rated Condition...................................................................................................................5

4.2 Operation Range...............................................................................................................................................7

4.3 Electrical Data..................................................................................................................................................7

5 PIPING DIAGRAM...................................................................................................................7

UNITS CONTROL.......................................................................................................9

1 OPERATION FLOWCHART...................................................................................................9

1.1 Cooling Operation............................................................................................................................................9

1.2 Heating Operation..........................................................................................................................................10

2 MAIN LOGIC...........................................................................................................................11

2.1 Cooling Mode..................................................................................................................................................11

2.2 Heating Mode..................................................................................................................................................11

2.3 Defrosting Mode.............................................................................................................................................12

3 WIRED CONTROLLER ........................................................................................................12

3.1 Dimension........................................................................................................................................................12

3.2 Function...........................................................................................................................................................13

3.3 Installation......................................................................................................................................................15

4 CONTROL WIRING DESIGN...............................................................................................16

UNITS INSTALLATION ..........................................................................................18

1 UNITS INSTALLATION.........................................................................................................18

1.1 Installation Positions......................................................................................................................................18

1.2 Matters need Attention..................................................................................................................................18

1.3 DIMENSION DATA.......................................................................................................................................18

1.4 INSTALLATION CLEARANCE DATA .....................................................................................................21

2 WATER PIPING WORK..........................................................................................................23

2.1 Installation Procedure....................................................................................................................................23