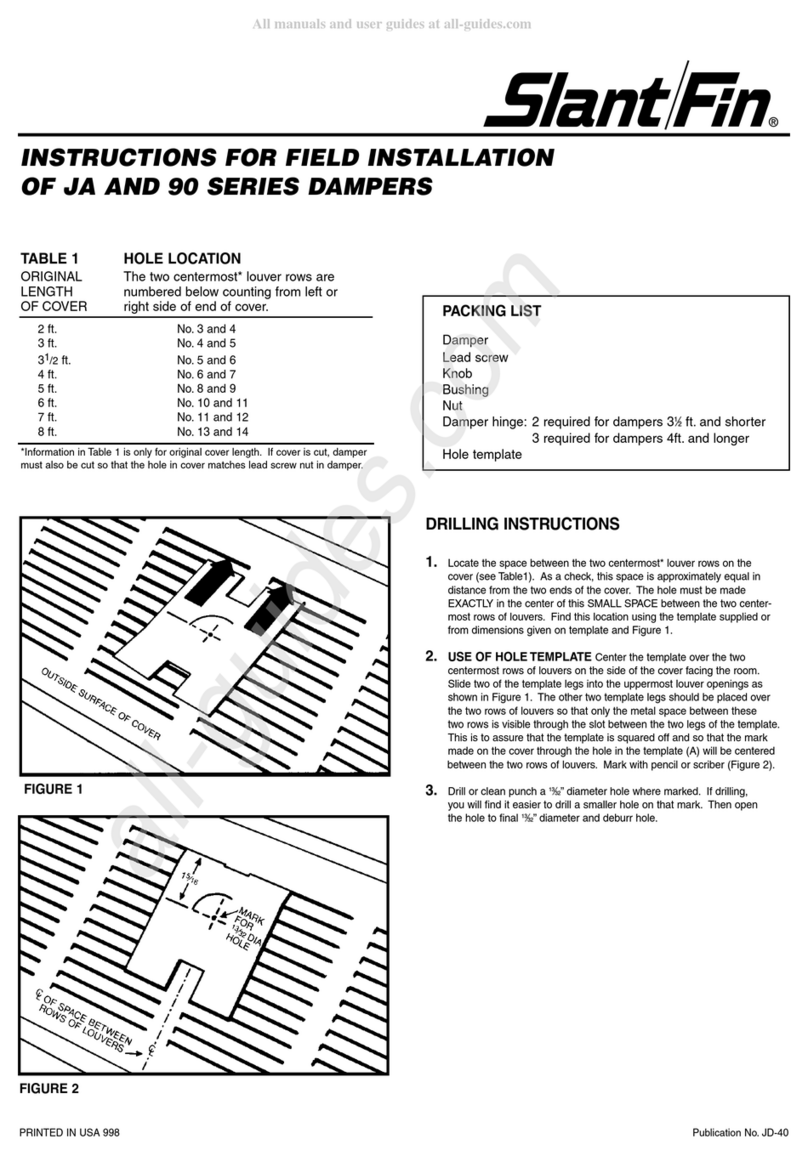

Counterbalance Adjustment

Procedure

The following instructions should be followed when

attempting to maximize the counterbalance effect

on the EM or GM model dampers. Be aware that

when the balance setting is highly sensitive, friction

wear, and contamination will have an adverse effect

to the operation of the damper. The sensitivity of

the counterbalance should only be set to meet the

application requirements. The damper must be mounted

square and plumb and operate freely before any weight

adjustments are performed.

Counterbalance Adjustment for

EM/ES/GM-30, 31, and 32: Vertical

Mount - Horizontal Airflow

There are two different adjustments that can be made:

Adjustment #1: affects the balance of the

blades in the open position. Use this adjustment

method if the damper blades do not achieve full

open position under airflow and you want them

to open further or all the way.

Adjustment #2: affects the balance of the blades

in the closed position along with a small change

to the open position balance.

If the airflow through the damper is light and the blades

only slightly move from the closed position, then

Adjustment #1 and #2 are required.

Adjustment #2: Balance the Blades in the Closed

Position

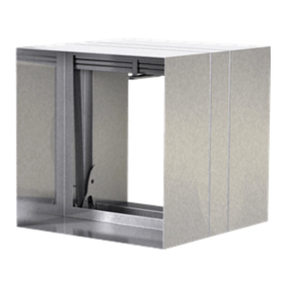

The damper is assembled with the counterbalance

weights and bracket installed such that, when the

blades are closed, the counterbalance weights and

bracket are positioned directly in-line with the blade

pivot points. This position of the weights will provide a

light load that will hold the blades in the closed position.

To reduce this load, the counterweight mounting

brackets can be bent away from the adjacent blade

surface. Bending the counterweight mounting brackets

will move the counterweight stack behind the blade

pivot point and therefore allow the blades to start

opening at lower airflow rates. This adjustment should

be performed in small increments since the blades will

not fully close if the brackets are bent too far.

Adjustment #1:Balance the Blades in the Open

Position

Moving the weight stack along the length of the

mounting bracket slot will affect the full open balance

of the blade assembly. Moving the weights further

away from the blade pivot point will cause the blades

to become more balanced so that at some point, and

with enough weight, the blades would remain open.

Care must be taken to ensure that when the weights

are moved outward from the blade pivot point they will

not interfere with the adjacent blade when the blades

close. Moving the weights back towards the blade pivot

point will allow the blades to close. If the damper blades

do not open completely and Adjustment #1 has been

addressed, then more weight(s) is required.

4) Damper must be installed into duct or opening square

and free of twist or other misalignment. Damper

must not be squeezed or stretched into duct or

opening. Out of square, racked, twisted or misaligned

installations can cause excessive leakage and/or

torque requirements to exceed damper/actuator

design.

5) Damper and actuator must be kept clean, dry and

protected from dirt, dust and other foreign materials

prior to and after installation. Examples of such

foreign materials include but are not limited to:

a) Mortar dust

b) Drywall dust

c) Firesafing materials

d) Wall texture

e) Paint overspray

6) Damper should be sufficiently covered as to prevent

overspray if wall texturing or spray painting will

be performed within 5 feet (1.50m) of the damper.

Excessive dirt or foreign material deposits on

damper can cause excessive leakage and/or torque

requirements to exceed damper/actuator design.

7) ACCESS: Suitable access (actuators maintenance,

etc.) must be provided for damper inspection and

servicing. Where it is not possible to achieve sufficient

size access, it will be necessary to install a removable

section of duct.

Bend counterweight mounting

bracket away from blades.

Bend Here

ES, EM, & GM Series Dampers2