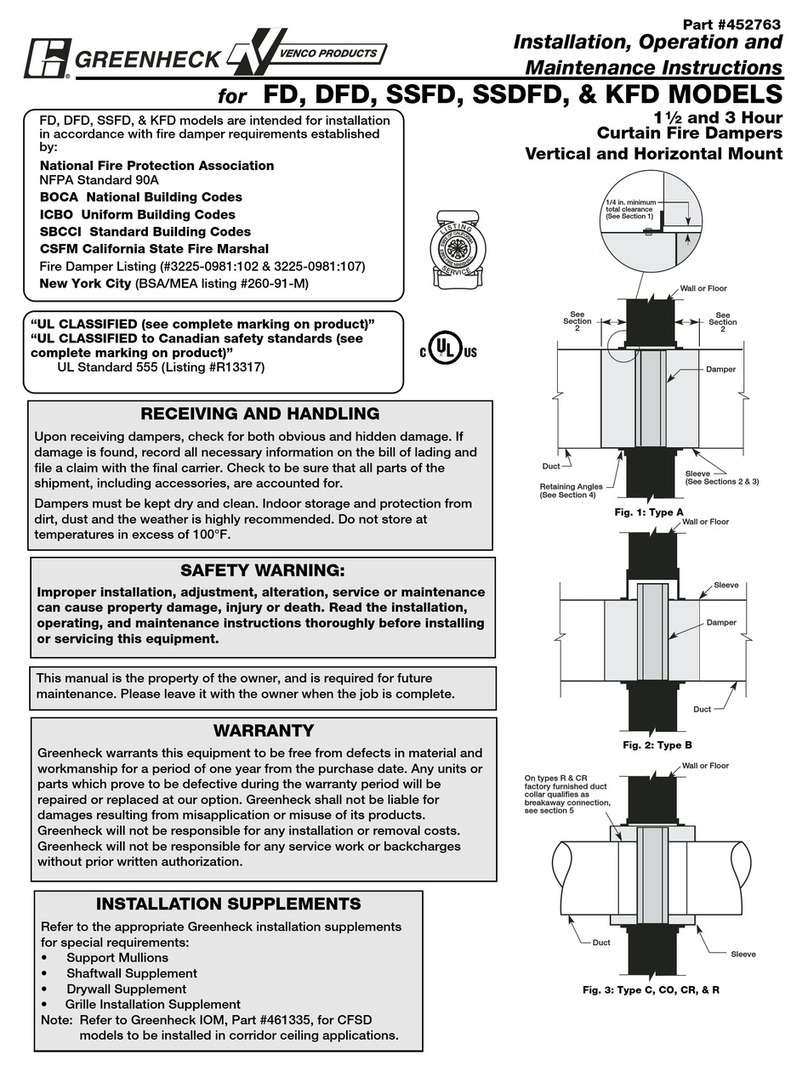

Greenheck HTD Series User manual

Other Greenheck Fire And Smoke Damper manuals

Greenheck

Greenheck FSD Series User manual

Greenheck

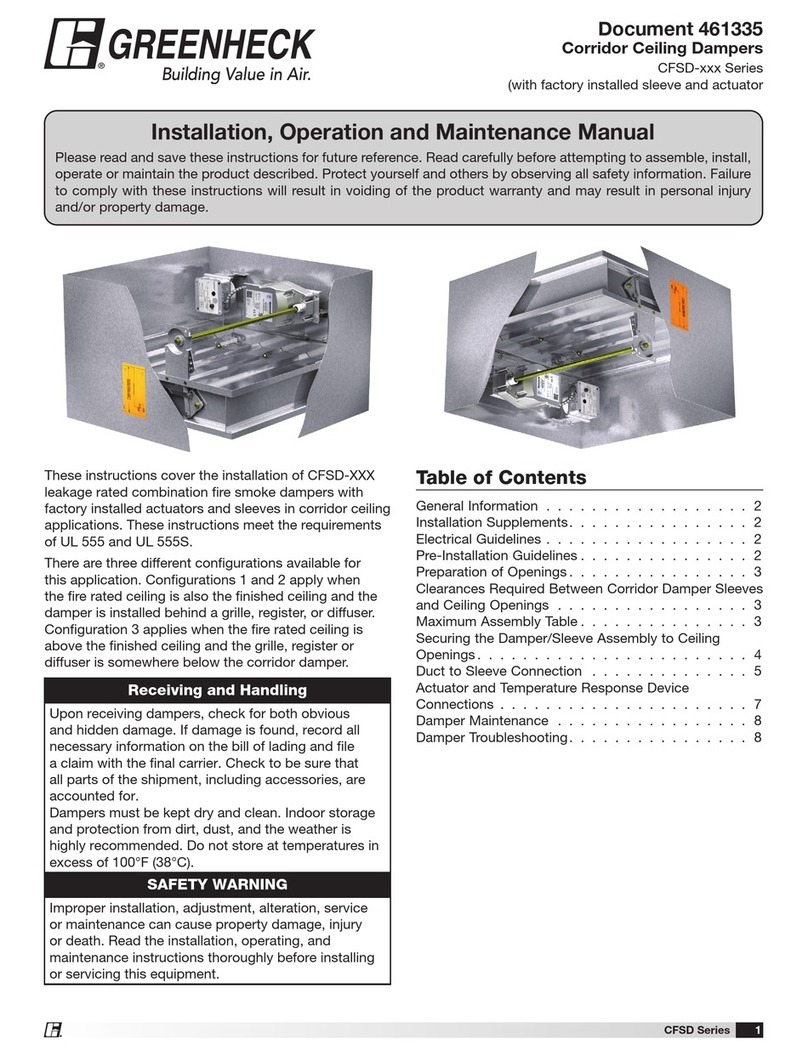

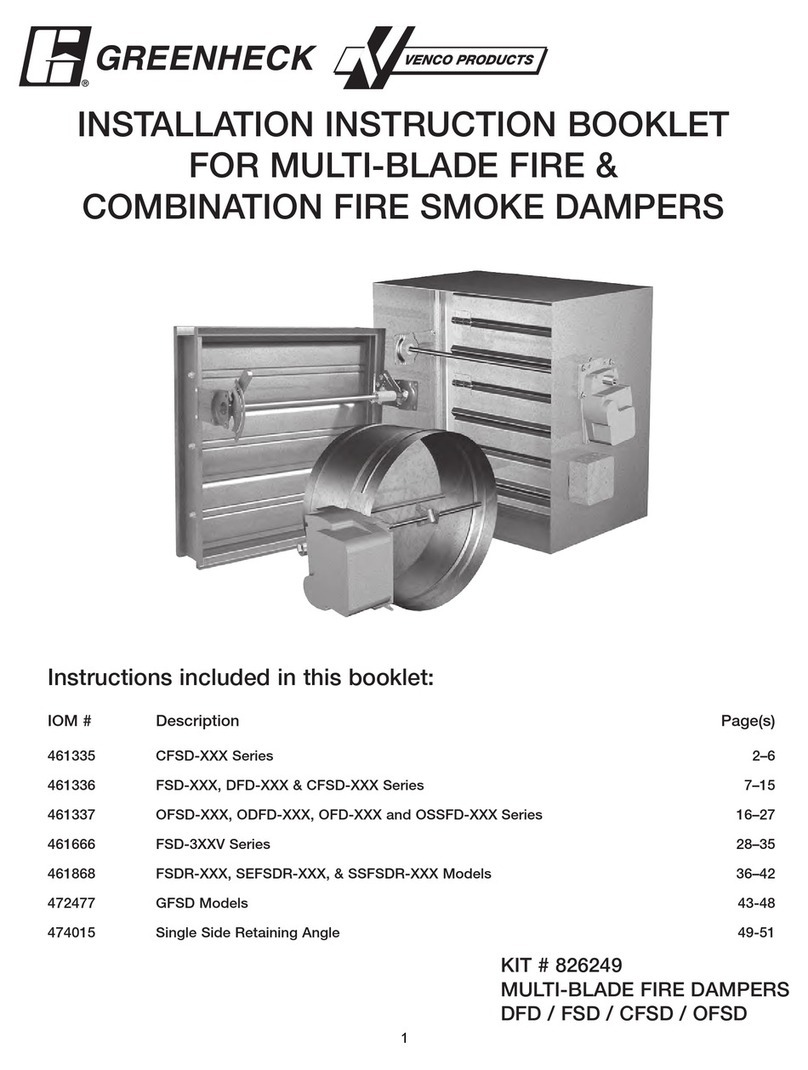

Greenheck CFSD Series User manual

Greenheck

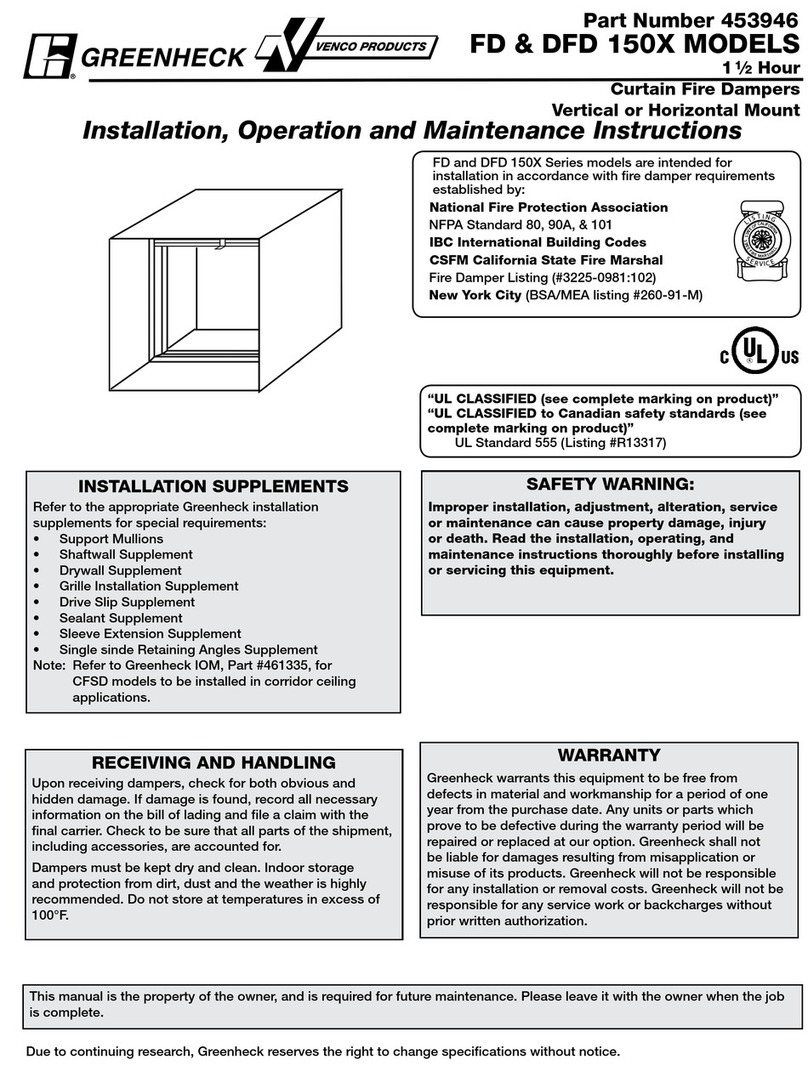

Greenheck FD150X Installation and operating instructions

Greenheck

Greenheck GFSD Series User manual

Greenheck

Greenheck HBS Series Manual

Greenheck

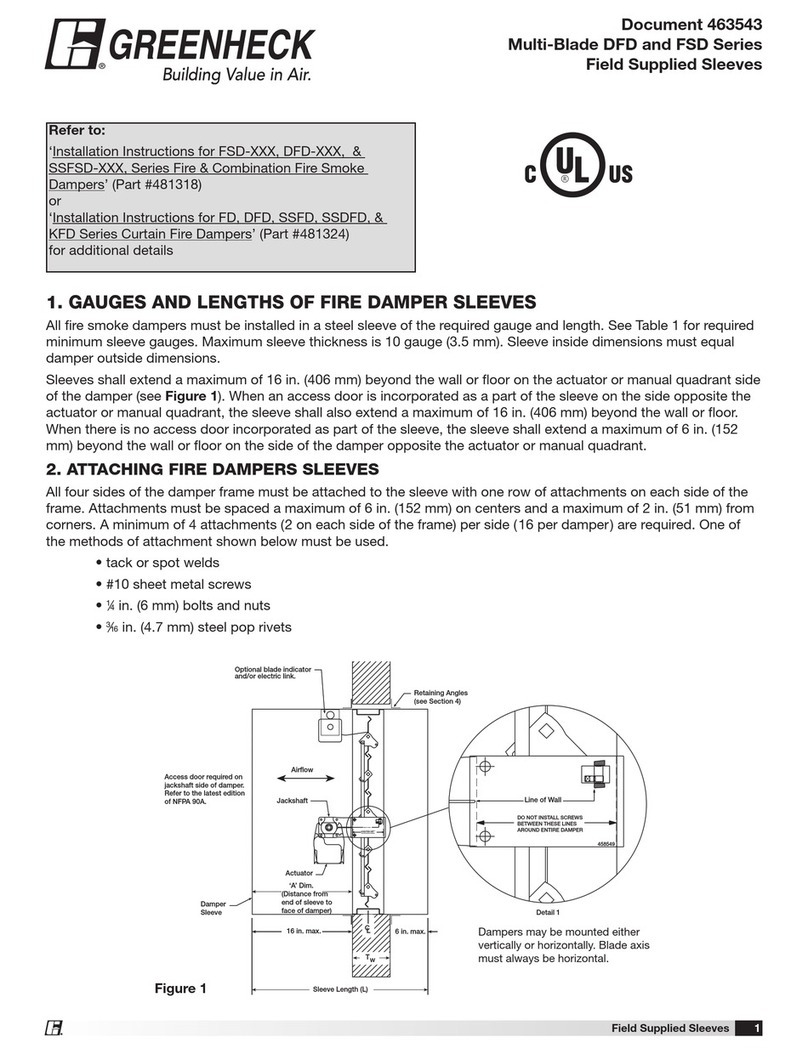

Greenheck DFD Series User manual

Greenheck

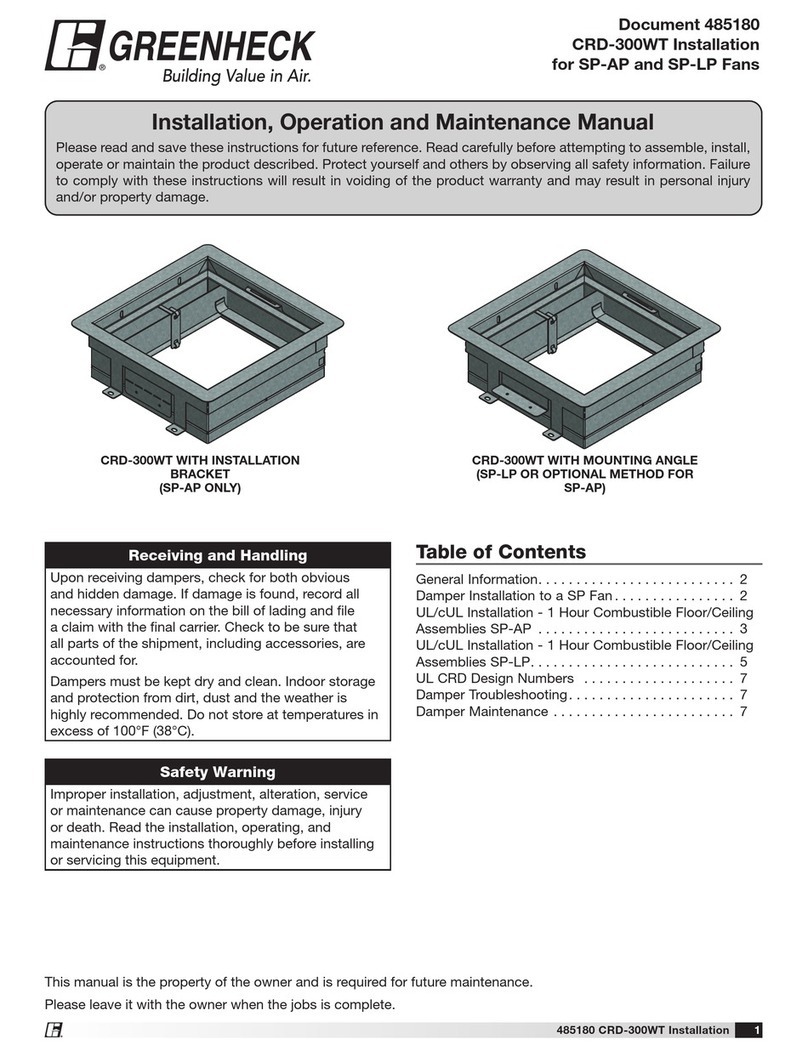

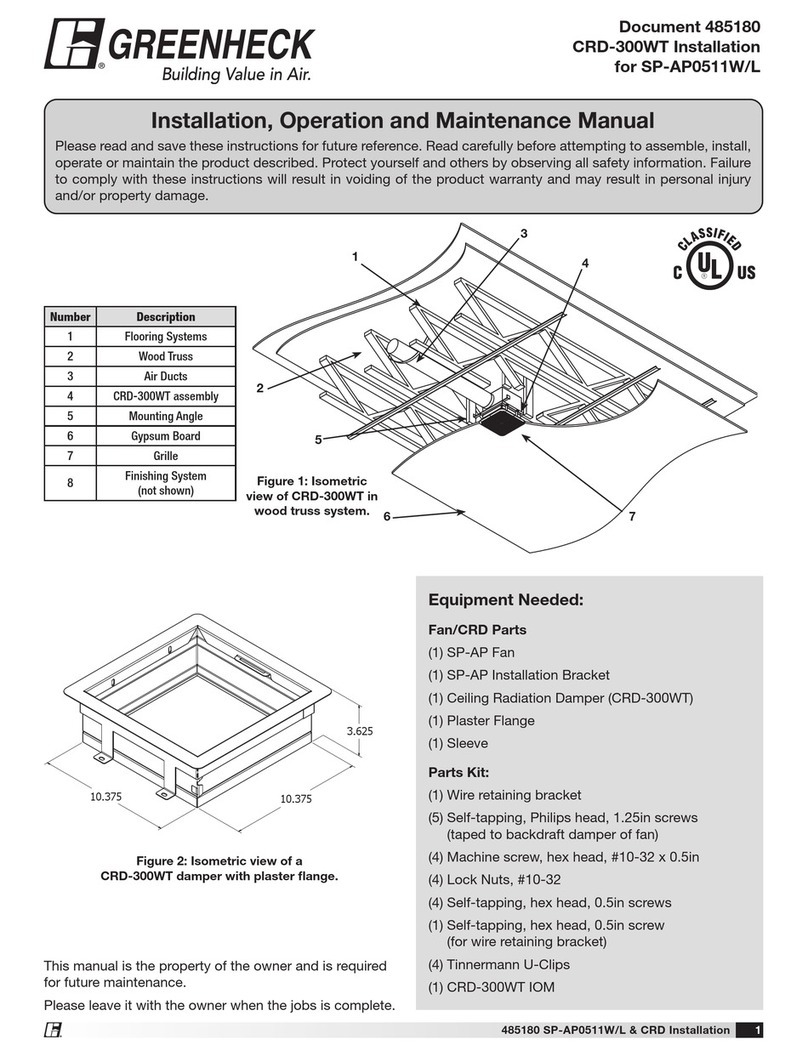

Greenheck CRD-300WT User manual

Greenheck

Greenheck VCD Series User manual

Greenheck

Greenheck FSD Series Manual

Greenheck

Greenheck CRD-1WT User manual

Greenheck

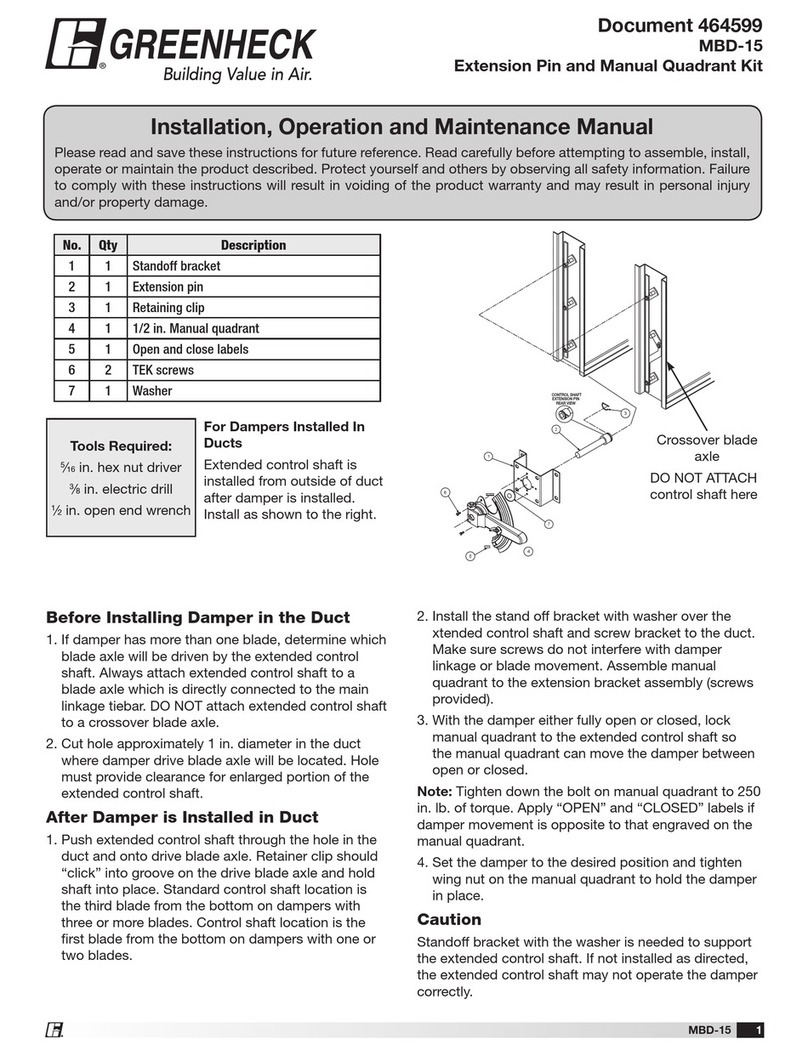

Greenheck MBD-15 User manual

Greenheck

Greenheck SMD Series User manual

Greenheck

Greenheck DFD Series User manual

Greenheck

Greenheck CFSD Series User manual

Greenheck

Greenheck Vektor-M Series User manual

Greenheck

Greenheck FD150X Manual

Greenheck

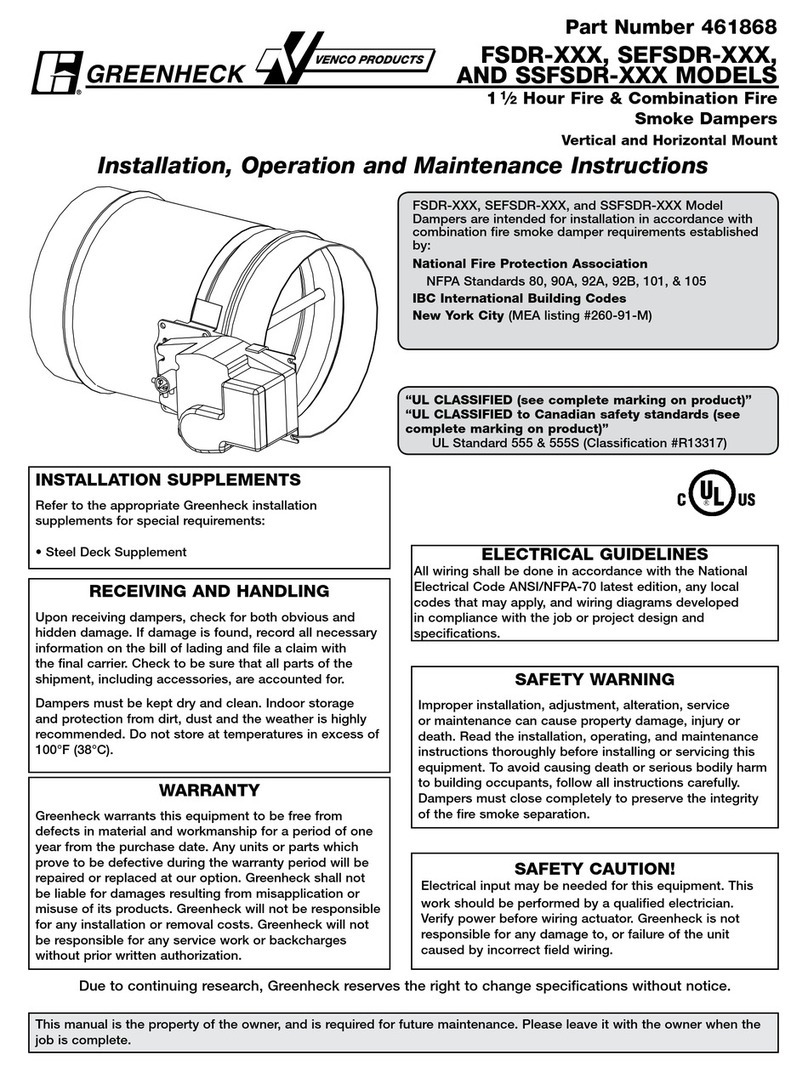

Greenheck FSDR Series Installation and operating instructions

Greenheck

Greenheck EHH-401 User manual

Greenheck

Greenheck FD Series Owner's manual

Greenheck

Greenheck CRD-300WT User manual

Popular Fire And Smoke Damper manuals by other brands

HVC

HVC NCA 700 Series Operation and maintenance manual

Wildeboer

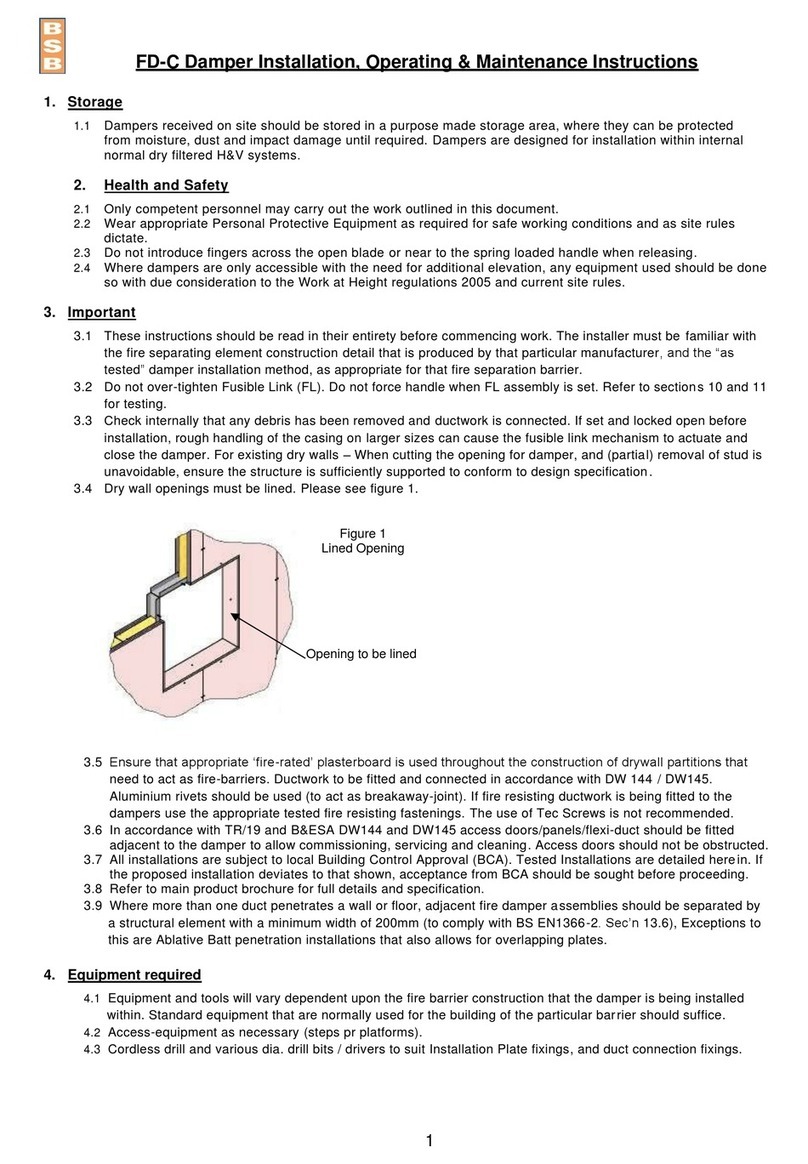

Wildeboer FR90 user manual

FläktGroup

FläktGroup ETCE Instructions for installation, operation and maintenance

Tamco

Tamco 1000 SM Series manual

Lindab

Lindab FBC2 Installation booklet

EKOVENT

EKOVENT EKO-SRB1 Installation, operating and maintenance instructions

Advanced Air

Advanced Air 0160 Series Installation, operation and maintenance manual

Swegon

Swegon Actionair CSS Series installation guide

TAKACHIHO

TAKACHIHO FYN-M 1 Series manual

Valmet

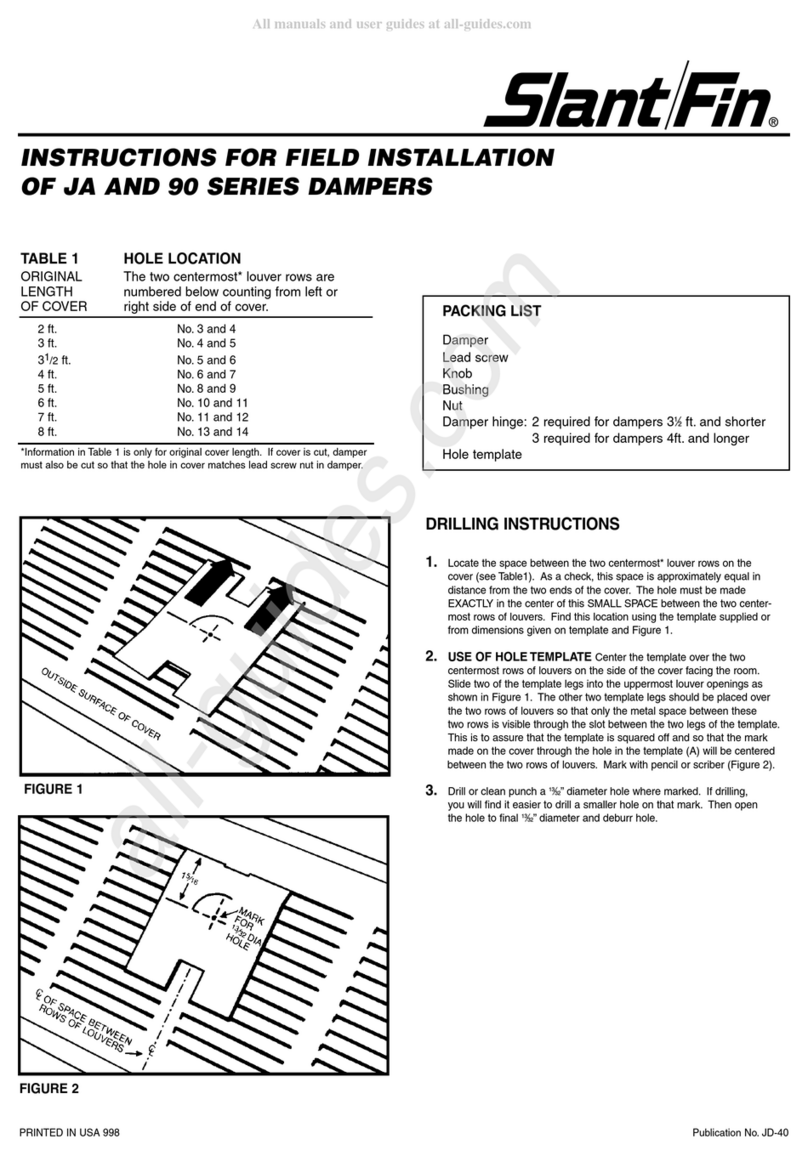

Valmet Flowrox Expulse Series Installation, operation and maintenance instructions

ETS NORD

ETS NORD NORDfire FDMB manual

Mandik

Mandik MSD manual